Abstract

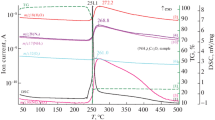

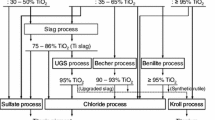

Ruthenium, as well as the rest of the platinum-group metals, is of crucial importance for industry due to its extraordinary catalytic activity and high-tech applications. Because of its scarcity and high value, there is an increasing interest towards its recovery from wastes. Chlorination metallurgy arises as one possible recovery method. The intrinsic kinetics of the chlorination of ruthenium oxide was studied with the aim of applying this process in a suitable recovery technology. Chlorination of RuO2 was investigated for temperatures between 973 K and 1073 K (700 °C and 800 °C) and chlorine partial pressure from 50 to 90 kPa. The reaction rate was measured by gravimetry and the rate equation was obtained. An activation energy of 259 ± 6 kJ mol−1 and a reaction order of 0.5 with respect of chlorine partial pressure were determined. The reaction product is unstable at atmospheric conditions. Formation of RuO2Cl2 is proposed based on experimental evidence; however, such product has not been confirmed yet.

Similar content being viewed by others

References

M. Pagliaro, S. Campestrini, R. Ciriminna. Ru-based oxidation catalysis, Chemical Society Reviews, 2005, 34, 837-845. doi:10.1039/b507094p.

E. Abd, H. Mahmoud, Y.M. Mikhail, and R.H. Blunk: Fast recycling process for ruthenium, gold and titanium coatings from hydrophilic PEM fuel cell bipolar plates. US 8323415, 2012.

S.D. Barnicki, J.S. Kanel, K.W. Hampton Jr., and E.G. Cervo: Method for recovery and recycle of ruthenium homogeneous catalysts. US 8829248, 2014.

D. Ikuta, O. Satoshi, and H. Takazawa: Recovery method of ruthenium. JP2013155391, 2013.

Y. Hirai, T. Maruko, and K. Seki: Method for recovering ruthenium. US 8454914, 2013.

B. Lai, L. Xu, Y. Han, Q. Liu, and D. Song: Method for recovering ruthenium from waste catalyst of aluminum oxide loaded with ruthenium. Patent Application WO 131453, 2013.

Henze, H. Urtel, M. Sesing, and M. Karches: Method for recovering ruthenium from spent catalysts containing ruthenium oxide. EP 2391740, 2014.

M. Bergeron and J.M. Lalancette. Dry chlorination of pgm-bearing chromite ores or concentrates, CA 2193783A1, 1998.

D.C. Craig, R.A. Grant. Refining of precious-metal containing concentrates by chlorination, EP 1072690 A1, (2001).

J.M. Lalancette. Method for the recovery of base and precious metals by extractive chloridation, WO 053788A1 2002.

M. Bergeron and M. Richer-Lafléche: Process for recovering platinum group metals from ores and concentrates, US 7972412 B2, 2011.

C. Kotze: Dry chlorine metallurgy PGM refining plant nears commercialization. Enginering News, August 23rd, 2013.

A.D. Westland, F.E. Beamish. Use of chlorine in the attack of novel metals, Analytical Chemistry, 1958, 30, 3, 414-418.

H. Over. Surface chemistry of ruthenium dioxide in heterogeneous catalysis and electrocatalysis: from fundamental to applied research, Chemical Reviews, 2012, 112, 3356-3426. doi: 10.1021/cr200247n.

M. Hevia, A. Amrute, T. Schmidt et al., Transient mechanistic study of the gas-phase HCl oxidation to Cl 2 on bulk and supported RuO 2 catalysts, Journal of Catalysis, 276, 2010, 1, 141-151. doi:10.1016/j.jcat.2010.09.009.

C.N. Guibaldo and G. De Micco, A.E.Bohé: Proc. Mater. Sci., 2015, DOI:10.1016/j.mspro.2015.04.144.

D. Crihan, M. Knapp, S. Zweidinger, E. Lundgren, C.J. Weststrate, J.N. Andersen, A.P. Seitsonen, H. Over. Stable Deacon Process for HCl Oxidation over RuO2. Angew. Chem. 2008, 47, 2131 –2134. doi: 10.1002/anie.200705124.

S. Zweidinger, D. Crihan, M. Knapp, J. P. Hofmann, A. P. Seitsonen, C. J. Weststrate, E. Lundgren, J. N. Andersen, H. Over. Reaction Mechanism of the Oxidation of HCl over RuO2(110). J. Phys. Chem. C, 112, 2008, 27, 9966-9969. doi:10.1021/jp803346q.

H. Hillebrecht, P.J. Schmidt, H.W. Rotter, G. Thiele, P. Zoennchen, H. Bengel, H.-J. Cantow, S.N. Magonov, M.-H. Whangbo: J. Alloys Compounds, 1997, 246, 70-79.

I.A. Ivanter, V.L. Kubasov, G.A. Vorob’ev, G.P. Pechnikova. Influence of conditions of the decomposition of ruthenium hydroxychloride, Zh. Prikl. Khim., 1977, 50, 4, 917-918.

S.A. Cotton. Chemistry of precious metals. Chapman & Hall, London, 1997.

J. M. Fletcher, W. E. Gardner, E. W. Hooper, K. R. Hyder, and J. L. Woodhead, Anhydrous Ruthenium Chlorides, Nature, 199, 1963, 1089.

K. Seki: Process for producing sopported ruthenium and process for producing chlorine. United States Patent, 7858065B2, 2010.

J. Szekely, J.W. Evans, and H.Y. Sohn: Gas-Solid Reaction. Academic Press, New York, NY, 1976.

Acknowledgments

The authors would like to thank the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) and Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT) for financially supporting this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 1, 2015.

Rights and permissions

About this article

Cite this article

Guibaldo, C.N., De Micco, G. & Bohe, A.E. Intrinsic Kinetics of the Chlorination of RuO2 with Cl2 Between 973 K and 1073 K (700 °C and 800 °C). Metall Mater Trans B 47, 983–988 (2016). https://doi.org/10.1007/s11663-015-0529-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0529-1