Abstract

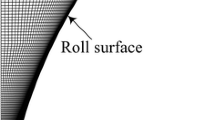

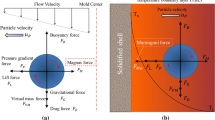

The commercialization of aluminum twin-roll casting was realized in the early 1950s, while it is still a dream for engineers to produce steel strip by this process. In the present paper, a two-dimensional mathematical model is employed to study the fluid flow, heat transfer, and solidification during the twin-roll casting for both steel and aluminum. The turbulent flow in the pool is examined using the Lam and Bremhorst low-Reynolds-number turbulence model. In order to facilitate the comparison and analysis, a new transformed coordinate system (r, φ) is established. Characteristics of the momentum boundary layer and the solidification front are described. Reasons of the formation of the wedge-shaped zone near the surface of rotating roll are given. In the transformed coordinate system (r, φ), the effect of the centrifugal force induced by the rotating roll is presented using the velocity component in the r direction and the pressure gradient in the r direction. At last, the evaluation of the solidified shell in the pool is analyzed. The results show that the twin-roll casting is a roll-rotating-driven process. The variation of the thickness of the momentum boundary layer can be divided into three stages and its thickness is very uniform at the last stage. Near the roll surface, there exists a wedge-shaped zone induced by the near-roll-surface shear flow that washes the mushy zone front, which increases the depth of the liquid pool and decreases the length of the rolling region. The rotating roll gives rise to the stirring effect to the pool region and the metal is moving away from the roll surface in the positive radial velocity region, and the effect of the centrifugal force becomes weak in the lower part of the pool. At the solidification front, the non-dimensional effective heat transfer coefficient distribution in steel twin-roll casting is larger than that in aluminum twin-roll casting. Considering that the turbulence level is determined by the flow pattern in the pool region, which demonstrates the importance of the geometry of the feeding system in steel twin-roll casting. The evaluation of the solidified shell in aluminum twin-roll casting is a parabolic growth, while in steel twin-roll casting, the parabolic growth only occurs in the lower part of the pool.

Similar content being viewed by others

References

H. Bessemer. US Patent. 1865, No. 49053.

S. Ge, M. Isac and R.I.L. Guthrie: ISIJ Int., 2012, vol. 52(12), pp. 2109–22.

S. Ge, M. Isac and R.I.L. Guthrie: ISIJ Int., 2013, vol. 53(5), pp. 729–42.

R. Cook, P.G. Grocock, P.M. Thomas, D.V. Edmmonds and J.D. Hunt: J. Mater. Process. Technol., 1995, vol. 55, pp. 76–84.

T. Haga, K. Tkahashi, M. Ikawaand and H. Watari: J. Mater. Process. Technol., 2004, vol. 153-154, pp. 42–47.

N. Zapuskalov: ISIJ Int., 2003, vol. 43(8), pp. 1115–27.

M.G. Xu, M.Y. Zhu and G.D. Wang: Metal. Mater. Trans. B, 2015, vol. 46B, pp. 1510–19.

C.K.G. Lam and K. Bremhorst: J. Fluids Eng., 1981, vol. 103, pp. 456–60.

B.G. Thomas and L.F. Zhang: ISIJ Int., 2001, vol. 41(10), pp. 1181–93.

M.E. Aboutalebi, M. Hasan and R.I.L. Guthrie: Metall. Trans., 1995, vol. 26B, pp. 731–44.

R.P. Tavares and R.I.L. Guthrie: Can. Metall. Q., 1998, vol. 37, pp. 241–50.

S.H. Seyedein and M. Hasan: Numer. Heat Transfer, 1997, vol. 31A, pp. 393–410.

W.-S. Kim, D.-S. Kim and A.V. Kuznetsov: Int. J. Heat Mass Transf., 2000, vol. 43, pp. 3811–22.

Y. Fujita, H. Sato, T. Kitagawa, S.–I. Nishioka, Y. Tsuchida and A. Ozeki: ISIJ Int., 1989, vol. 29(6), pp. 495–502.

M.C. Flemings: Metall. Trans., 1991, vol. 22B, pp. 269–93.

J.A. Sekhar: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 1213–15.

R.P. Tavares, M. Isac, F.G. Hamel and R.I.L. Guthrie: Metall. Mater. Trans. B, 2001, vol. 32B, pp. 55–66.

R.P. Tavares, M. Isac and R.I.L. Guthrie: ISIJ Int., 1998, vol. 38(12), pp. 1353–61.

D. Bouchard, F.G. Hamel, S.F. Turcotte and J.-P. Nadeau: ISIJ Int., 2001, vol. 41(12), pp. 1465–72.

J.D. Hwang, H.J. Lin, J.S.C. Jang, W.S. Hwang and C.T. Hu: ISIJ Int., 1996, vol. 36(6), pp. 690–99.

C. Pfeiler, B.G. Thomas, M. Wu, A. Ludwig and A. Klaricha: Steel Res. Int., 2008, vol. 79, pp. 599–607.

B.G. Thomas, R.O. O’Malley, and D. Stone: in Proc. MCWASP VIII, B.G. Thomas and C. Beckermann, eds., TMS Publication, Warrendale, 1998, pp. 1185–92.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted on March 21, 2015.

Rights and permissions

About this article

Cite this article

Xu, M., Zhu, M. Numerical Simulation of the Fluid Flow, Heat Transfer, and Solidification During the Twin-Roll Continuous Casting of Steel and Aluminum. Metall Mater Trans B 47, 740–748 (2016). https://doi.org/10.1007/s11663-015-0486-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0486-8