Abstract

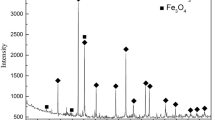

A Ghatshila chalcopyrite concentrate (average particle size, 50 μm) containing primarily CuFeS2 and SiO2 (Cu 16 pct) was reduced by a stream of hydrogen in a thermogravimetric analyzer (TGA) at selected temperatures [1173 K to 1323 K (900 °C to 1050 °C)], hydrogen flow rates, partial pressures of hydrogen (0.33 × 101.3 to 101.3 kPa), and sample bed heights. The product was a mixture of Cu (26 pct), SiO2, CuFeO2, and Fe. The rate equations for the three typical controlling mechanisms, namely, gas film diffusion (mass transfer), pore diffusion, and interfacial reaction, have been derived for the system geometry under study and applied to identify the rate-controlling steps. The first stage of the reduction, which extended up to the first 13 minutes, was rate controlled by the interfacial reaction. The last stage, which spanned over the last 60 to 120 minutes and accounted for a small percentage of reduction, was controlled by pore diffusion through the built-up Cu (and Fe) layer. The activation energy in the first stage was 101 kJ mol−1 and that in the second stage was 76 kJ mol−1. Subsequent acid leaching with 1 M HCl solution of the reduction product removed all soluble species, leaving a Cu (53.3 pct) + SiO2 mixture, with a small concentration (2.7 pct) of Cu2O in it. This result compares well with the predicted final mixture of Cu (59 pct)-SiO2 based on a mass balance on the starting concentrate. A follow-up heating at 1523 K (1250 °C) produced a sintered Cu-SiO2 composite with spherical copper particles of 400 µm diameter embedded in a silica matrix. Elemental chemical analyses were carried out by energy-dispersive X-ray spectroscopy/atomic absorption spectroscopy. The phase identification and microstructural characterization of Cu-SiO2 mixtures were carried out by X-ray powder diffraction and optical microscopy.

Similar content being viewed by others

Abbreviations

- \( C \) :

-

Total concentration of the gaseous species (=p/RT, p being the total pressure of the system)

- \( C_{{i_{\text{in}} }} \) :

-

Concentration of species i at inlet (=0, when i = H2S)

- \( C_{{i_{\text{eq}} }} \) :

-

Concentration of species i at equilibrium

- D AB :

-

Interdiffusion coefficient of A and B

- \( D_{\text{pore}} \) :

-

Pore diffusivity

- \( E \) :

-

Activation energy

- \( J^{*}_{i( - z)} \) :

-

Diffusion flux of species i relative to velocity of the mixture ((in –z direction)

- \( k^{\prime}_{f} \) :

-

Rate constant

- \( K_{\text{c}} \) :

-

Equilibrium constant in terms of concentration

- K :

-

Equilibrium constant in terms of activities

- \( N_{i( - z)} \) :

-

Diffusion flux of species i with respect to stationary coordinate (in −z direction)

- n i :

-

Moles of the species i

- \( p_{i} \) :

-

Partial pressure of species i

- R :

-

Universal gas constant

- \( S \) :

-

Cross-sectional area of the crucible

- t :

-

Time

- T :

-

Temperature (K)

- \( W_{{i\left( { - z} \right) }} \) :

-

Molar rate of diffusion of i (in −z direction)

- WP Cu :

-

Weight percentage of copper

- W(t):

-

Percentage weight of the sample at t = t relative to the initial weight W(0) = 100

- x i :

-

Mole fraction of species i

- \( X_{{{\text{CuFeS}}_{2} }} \) :

-

Fractional weight loss of chalcopyrite (CuFeS2) concentrate

- \( z_{1}^{0 } \) :

-

Initial bed height

- \( z_{2} \) :

-

Crucible height

- \( \rho_{{m_{{{\text{CuFeS}}_{2} }} }} \) :

-

Molar density of CuFeS2

References

J. R. Davis: Copper and Copper Alloys. ASM international, Materials Park, OH, 2001.

F. Habashi and R. Dugdale: Metall. Trans., 1973, vol. 4(8), pp. 1865–71.

T. R. Mankhand, V. V. P. Rao and P. M. Prasad: Metallography, 1981, vol. 14(4), pp. 335–45

H. Y. Sohn and S. Won: Metall. Trans. B, 1985, vol. 16B, pp. 831–39.

H. Y. Sohn and S. Won: Metall. Trans. B, 1985, vol. 16B, pp. 645–61.

M. Mohan, T. Mankhand and P. Prasad: Metall. Trans. B, 1987, vol. 18B, pp. 719–25.

T. Tanaka, H. Shimamura and K. Jibiki: Z. Phys. Chem., 1968, vol. 61(1), pp. 133–42.

Y. K. Rao and H. Bagheri: React. Solid., 1988, vol. 5(1), pp. 29-51.

X. Jhang, D. Zhang, X. Ni, J. Chen and H. Zheng: Mater. Res. Bull., 2008, vol. 43, pp. 2421–26

I. Zamblau, S. Varvara and L. M. Muresan: J. Mater. Sci., 2011, vol. 46, pp. 6484–90.

K. Zhang, C. H. Chew, G. Q. Xu, J. Wang and L. M. Gan: Langmuir, 1999, vol. 15, pp. 3056–61

G.A. Li, T.L. Zhu, Z.X. Deng, Y.J. Zhang, F. Jiao, H.R. Zheng: Chinese Sci. Bull., 2011, vol. 56(7), 685–90.

A. Z. Jin, Y. G. Wang and Z. Zhang: J. Crystal Growth, 2003, vol. 252, pp. 167–73.

R. Barve, R. R. Patil, N. P. Gaikwad, R. Pradeep, B. C. Bhatt, S. V. Moharil and M. S. Kulkarni, Nucl. Instum. Meth. B, 2012, vol. 289, pp. 100–05

R. F. Haglund, L. Yang, R. H. Magruder, C. W. White, R. A. Zhur, L. Yang, R. Dorsinville and R. R. Alfano: Nucl. Instrum. Methods B, 1994, vol. 91, p. 493.

A. P. Alivisatos: J. Phys. Chem., 1996, vol. 100, p. 13266.

U. Kreibig and M. Vollmer: Optical Properties of Metal Clusters, Springer, Berlin, 1995.

P. Chakraborty: J. Mater. Sci., 1998, vol. 33, pp. 2235–49.

E. T. Turkdogan, Physical Chemistry of High Temperature Technology, Academic Press, New York, NY, 1980, pp. 10-11

O. Kubaschewski, C. B. Alcock and P. J. Spencer, Materials Thermochemistry, Pergamon Press, Tarrytown, New York, 1993, pp. 258–323.

R. B. Bird, W. E. Stewart, and E. N. Lightfoot: Transport Phenomena, John Wiley and Sons, New York, NY, 1960, pp. 511.

R. Chatterjee and D. Ghosh: Metall. Trans. B, 2013, vol. 44B, pp. 1049–54.

Acknowledgments

One of the authors (R. Chatterjee) gratefully acknowledges the financial support of the University Grants Commission (Government of India) research fellowship scheme.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 27, 2015

Appendix

Appendix

Derivation of the Rate Equations (Eqs. [5–7])

Gas film diffusion-controlled kinetics

According to the shell mass balance over a shell thickness Δz in the gas film inside the crucible shown in Figure 1,

The species A is the reactant gas (H2, in the current study) and species B, which will be used subsequently, is the product gas (H2S, in the current study) in the gas-solid reaction given by Eq. [4]. At the steady state, the accumulation term disappears and since no chemical reaction occurs within the gas film, the relation simplifies to

The diffusion flux with respect to stationary coordinate, in mol area−1 time−1, is given by

where the first term in the right-hand side is the flux relative to the velocity(v*) of the gas mixture and the second term is the flux due to the velocity of the gas mixture. The second term is zero in the present case, because, according to Reaction [4], the number of moles of the reacting gas is equal to the number of moles of the produced gas. This represents a case of equimolar counterdiffusion for which N A(−z) = −N B(−z). Applying Fick’s first law of diffusion to the first term of the right-hand side of Eq. [A4], the relation reduces to

In Eq. [A6], at a given temperature, C and D AB are constants, because

and \( D_{\text{AB}} \), interdiffusion coefficient of A–B, is not a function of concentration for a low-density binary gas mixture. These give \( \frac{\text{d}}{{{\text{d}}z}}\left( {\frac{{{\text{d}}x_{A} }}{{{\text{d}}z}}} \right) = 0 \), which on two successive integration gives \( \frac{{{\text{d}}x_{A} }}{{{\text{d}}z}} = C_{1} \) and \( x_{A} = C_{1} z + C_{2} \), which is the equation of the concentration profile in terms of the two integration constants C 1 and C 2. The value of C 1 can be evaluated with the help of the following two boundary conditions (a) at \( z = z_{1}^{0} \), \( x_{A} = x_{{A_{\text{eq}} }} \) and (b) at \( z = z_{2} \), \( x_{A} = x_{{A_{\text{in}} }} \) as \( (x_{{A_{\text{in}} }} - x_{{A_{\text{eq}} }} )/(z_{2} - z_{1}^{0} ) \). Subscript ‘in’ stands for inlet gas and ‘eq’ stands for equilibrium. Substituting the value of C 1

Now, the molar rate of diffusion (in mol time−1) of A, W A(−z), is equal to the molar rate of removal of A through chemical reaction (Reaction [4]), \( - {\text{d}}n_{{{\text{H}}_{2} }} /{\text{d}}t \), since the two steps (mass transfer and interfacial reaction) are in series, and the latter is equal to \( 2( - {\text{d}}n_{{{\text{CuFeS}}_{2} }} /{\text{d}}t) \)from the stoichiometry of Reaction [4].

Since W A(−z) = S·N A(−z) (S is the cross-sectional area of the crucible), and from Eq. [A8],

Letting \( A_{1} = \frac{S}{2} \cdot C \cdot D_{\text{AB}} \frac{{x_{{A_{\text{in}} }} - x_{{A_{\text{eq}} }} }}{{z_{2} - z_{1}^{0} }} = {\text{constant}} \), the integration of Eq. [A9] gives

Now, fractional weight loss of CuFeS2 sample is given as follows:

In Eq. [A11], \( \rho_{{m_{{{\text{CuFeS}}_{2} }} }} \)is the molar density of CuFeS2. Replacing A by H2

The above equation is the rate equation, consistent with the system geometry under study, for gas film diffusion-controlled kinetics. Equation [A13] is reproduced as Eq. [5] in the text.

Pore diffusion-controlled kinetics

Unlike the gas film diffusion-controlled kinetics in which the gas film thickness is constant (steady), the pore diffusion involves a moving boundary (between porous product and CuFeS2 powder, in Figure 1) in which the thickness of the diffusion zone (i.e., the thickness of the porous product) increases with time. The shell mass balance over a shell thickness Δz in the pore diffusion zone gives, as in Eq. [A1], (Molar rate of A in) − (Molar rate of A out) = (Molar rate of accumulation of A),

This is a case of pseudo-steady-state diffusion (since the product/reactant boundary is a moving one), for which also the accumulation term is zero.

As considered previously, the diffusion flux with respect to stationary coordinate (in mol area−1 time−1) is given as follows:

The second term is, again, zero due to the equimolar counter diffusion. Applying Fick’s first law to the first term of the right-hand side

Bringing the two constant terms C and D pore out of the differentiation and integrating twice with the two boundary conditions: (a) at z = z 01 , \( x_{A} = x_{{A_{\text{in}} }} \), and (b) at z = z 1, \( x_{A} = x_{{A_{\text{eq}} }} \), the diffusion flux of A becomes, as before,

where z 1 is a function of t in accordance with the pseudo-steady state. The molar rate of diffusion (in mol time−1) of A:

The molar rate of diffusion of A (H2) at the product/reactant interface being equal to the molar rate of removal of H2 by the interfacial reaction (Reaction [4]) because the two steps are in series and using the stoichiometry of Reaction [4], as before, and Eq. [A19], the following equalities are obtained:

In Eq. [A20], \( {\text{A}}_{2} = \frac{{C \cdot D_{\text{pore}} (x_{{A_{\text{in}} }} - x_{{A_{\text{eq}} }} )}}{{2 \rho_{{m_{{{\text{CuFeS}}_{2} }} }} }} \) = constant. The fractional weight loss of CuFeS2 sample is given as follows:

Substitution of \( z_{1} \) from Eqs. [A21] into [A20] gives

On simplification and substituting back the value of A2 and replacing A by H2

The above equation is the rate equation, consistent with the system geometry under study, for pore diffusion-controlled kinetics. Eq. [A22] is reproduced as Eq. [6] in the text.

Interfacial reaction-controlled kinetics

To derive the rate equation for the interfacial reaction-controlled kinetics, Reaction [4] is considered as elementary as well as reversible and first order with respect to H2. Accordingly, the reaction is rewritten as follows:

In this case, there should be no concentration gradient across the gas film within the crucible as well as across the porous product layer because both gas film diffusion and pore diffusion steps are kinetically fast. Consequently, the hydrogen concentration at z = z 1 (which is the interface of the product and the reactant CuFeS2 and where the interfacial reaction takes place) is the same as that in the inlet gas, namely\( C_{{{\text{H}}_{{2_{\text{in}} }} }} \).The rate of the reaction, in terms of removal of hydrogen, is

where k f is the forward rate constant, k b is the backward rate constant, and \( k^{\prime}_{\text{f}} = k_{\text{f}} C_{{{\text{CuFeS}}_{2} }}^{{{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-0pt} \!\lower0.7ex\hbox{$2$}}}} \) is the modified forward rate constant and \( k^{\prime}_{\text{b}} = k_{\text{b }} C_{\text{Cu}}^{{{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-0pt} \!\lower0.7ex\hbox{$2$}}}} C_{\text{Fe}}^{{{\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 2}}\right.\kern-0pt} \!\lower0.7ex\hbox{$2$}}}} \) is the modified backward rate constant. It is to be noted that the concentrations \( C_{{{\text{CuFeS}}_{2} }} \), C Cu, and C Fe are constant with respect to time.

Using the stoichiometry, as before, the following equalities are obtained:

At equilibrium,\( - \frac{1}{S}\frac{{{\text{d}}n_{{{\text{CuFeS}}_{2} }} }}{{{\text{d}}t}} = 0,\;\frac{{k^{\prime}_{\text{f}} }}{{k^{\prime}_{\text{b}} }} = \left( {\frac{{C_{{{\text{H}}_{2} {\text{S}}}} }}{{C_{{{\text{H}}_{2} }} }}} \right)_{\text{eq}} = K_{\text{c }} \), where

where \( K_{\text{c}} \) is the equilibrium constant in terms of concentration and K is the equilibrium constant in terms of activity. This allows Eq. [A25] to be rewritten as follows:

Letting \( A_{3} = \frac{{k^{\prime}_{\text{f}} }}{2}\left[ {C_{{{\text{H}}_{{2_{\text{in}} }} }} - \frac{{C_{{{\text{H}}_{2} {\text{S}}_{\text{in}} }} }}{K}} \right], \) where A 3 is a constant that does not change with t,

From Eq. [A21],

Putting back the value of A3 in Eq. [A26],

The above equation is the rate equation, consistent with the system geometry under study, for interfacial reaction-controlled kinetics. Eq. [A27] is reproduced as Eq. [7] in the text.

Rights and permissions

About this article

Cite this article

Chatterjee, R., Ghosh, D. Kinetics of Hydrogen Reduction of Chalcopyrite Concentrate. Metall Mater Trans B 46, 2692–2705 (2015). https://doi.org/10.1007/s11663-015-0419-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0419-6