Abstract

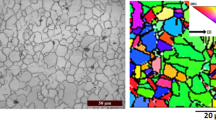

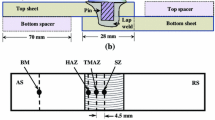

AZ31B-H24 Mg alloy sheets with a thickness of 2 mm were friction stir welded in lap configuration using two tool rotational rates of 1000 and 1500 rpm and two welding speeds of 10 and 20 mm/s. The residual stresses in the longitudinal and transverse directions of the weldments were determined using X-ray diffraction. The shear tensile behavior of the lap joints was evaluated at low [233 K (−40 °C)], room [298 K (25 °C)], and elevated [453 K (180 °C)] temperatures. The failure load was highest for the lower heat input condition that was obtained at a tool rotational rate of 1000 rpm and a welding speed of 20 mm/s for all the test temperatures, due to the smaller hooking height, larger effective sheet thickness, and lower tensile residual stresses, as compared to the other two welding conditions that were conducted at a higher tool rotational rate or lower welding speed. The lap joints usually fractured on the advancing side of the top sheet near the interface between the thermo-mechanically affected zone and the stir zone. Elevated temperature testing of the weld assembled at a tool rotational rate of 1000 rpm and a welding speed of 20 mm/s led to the failure along the sheet interface in shear fracture mode due to the high integrity of the joint that exhibited large plastic deformation and higher total energy absorption.

Similar content being viewed by others

Abbreviations

- AS:

-

Advancing side

- BM:

-

Base metal

- CRSS:

-

Critical-resolved shear stress

- EST:

-

Effective sheet thickness

- ET:

-

Elevated temperature

- FSW:

-

Friction stir welding

- HAZ:

-

Heat-affected zone

- LD:

-

Longitudinal direction

- LT:

-

Low temperature

- RD:

-

Rolling direction

- RS:

-

Retreating side

- RT:

-

Room temperature

- SEM:

-

Scanning electron microscope

- SZ:

-

Stir zone

- TD:

-

Transverse direction

- TMAZ:

-

Thermo-mechanically affected zone

- XRD:

-

X-ray diffraction

References

J. Murray and D. King: Nature, 2012, Vol. 481, pp. 433-35.

E. Aghion, B. Bronfin, and D. Eliezer: J. Mater. Process. Tech, 2001, Vol. 117, pp. 381-85.

Q. Schiermeier: Nature, 2011, Vol. 316, pp. 470-71.

X. Cao, M. Jahazi, J.P. Immarigeon, and W. Wallace, J. Mater. Process. Tech, 2006, Vol. 171, pp. 88-204.

T.M. Pollock: Science, 2010. Vol. 328, pp. 986-87.

J.F. Nie, Y.M. Zhu, J.Z. Liu and X.Y. Fang: Science, 2013, Vol. 340, pp. 957-60.

W. Yuan, R.S. Mishra, B. Carlson, R. Vermac and R.K. Mishra: Mater. Sci. Eng. A, 2012, Vol. 543, pp. 200-209.

X. Cao and M. Jahazi: Mater. Des, 2009, Vol. 30, pp. 2033-2042.

S.M. Chowdhury, D.L. Chen, S.D. Bhole, and X. Cao: Procedia Engineering, 2010, Vol. 2, pp. 825-33.

C. Liu, D.L. Chen, S.D. Bhole, X. Cao, X and M. Jahazi: Materials Characterization, 2009, Vol. 60, pp. 370-76.

N. Afrin. D.L. Chen, X. Cao and M. Jahazi: Mater. Sci. Eng. A, 2008, Vol. 472(1-2), pp. 179-186.

B.S. Naik, D.L. Chen, X. Cao and P. Wanjara: Metall. Mater. Trans. A, 2013, Vol. 44A, pp. 3732-46.

B.S. Naik, D.L. Chen, X. Cao and P. Wanjara: Metall. Mater. Trans. A, 2014, Vol. 45 (10), pp. 4333-49.

H.J. Liu, H. Fuji, M. Maeda and K. Nogi: J. Mater. Process. Tech, 2003, Vol. 143, pp. 692-96.

J. Yang, B.L. Xiao, D. Wang and Z.Y. Ma: Mater. Sci. Eng. A, 2010, Vol. 527, pp. 708-14.

A. RazalRose, K. Manisekar and V. Balasubramanian: Trans. Nonferrous Met. Soc. China, 2011, Vol. 21, pp. 974-84.

D. Liu, H. Nishio and K. Nakata: Mater. Des, 2011, Vol. 32, pp. 4818-24.

H. Omar, V.R. Iris, and M. Arif: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2867–74.

G. Bussu and P.E. Irving: Int. J. Fatigue, 2003, Vol. 25, pp. 77-88.

A. Macwan, D.L. Chen, M. Marr and O. Kesler: J. Power. Sources, 2013, Vol. 221, pp. 397-405.

ASTM International Standard ASTM D3164-03, “Standard Test Method for Strength Properties of Adhesively Bonded Lap-Shear Sandwich Joints in Shear by Tensile Loading”, 2011.

K. Deplus, A. Simar, W. Van Haver, and B. De Meester: Inter. J. Adv. Manufact. Tech, 2011, vol. 56, pp. 493–504.

O.J. Dada, C. Polese, and L.A. Cornish: Proc. Int. Multi Conf. Eng. Comput. Sci., Hong Kong, 2013, vol. II, IMECS 2013, 2013.

L. Commin, M. Dumont, R. Rotinat, F. Pierron, J. E. Masse and L. Barrallier: Mater. Sci. Eng. A, 2012, Vol. 551, pp. 288-92.

X. Cao and M. Jahazi: Mater. Des, 2011, Vol. 32, pp. 1-11.

Y.Chino, K. Sassa, and A. Kamiya: Mater. Sci. Eng. A, 2006, Vol. 441(1-2), pp. 349-56.

J. Koike, Y. Sato and D. Ando: Mater. Trans, 2008, Vol. 49(12), pp. 2792-2800.

B.H. Lee, K.S. Shin and C.S. Lee: Mater. Sci. Forum, 2005, Vol. 475-479(IV), pp. 2927-30.

H. Takuda, T. Morishita, and T. Kinoshita: J. Mater. Process. Tech, 2005, Vol. 164-165, pp. 1258-62.

Acknowledgments

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC) and AUTO21 Network of Centers of Excellence for providing financial support. The authors also thank Professor A.A. Luo from Ohio State University (formerly with General Motors Research and Development Center) for providing the test materials. One of the authors (D.L. Chen) is grateful for the financial support by the Premier’s Research Excellence Award (PREA), NSERC-Discovery Accelerator Supplement (DAS) Award, Automotive Partnership Canada (APC), Canada Foundation for Innovation (CFI), and Ryerson Research Chair (RRC) program. The assistance of Q. Li, A. Machin, J. Amankrah, R. Churaman, and M. Guerin (NRC) in performing the experiments is gratefully acknowledged. The authors also thank Professor S.D. Bhole for the helpful discussion.

Author information

Authors and Affiliations

Corresponding authors

Additional information

The following statement pertains only to authors X. Cao and P. Wanjara: Published with permission of the Crown in Right of Canada, i.e., the Government of Canada.

Manuscript submitted December 11, 2014.

Rights and permissions

About this article

Cite this article

Naik, B.S., Cao, X., Wanjara, P. et al. Residual Stresses and Tensile Properties of Friction Stir Welded AZ31B-H24 Magnesium Alloy in Lap Configuration. Metall Mater Trans B 46, 1626–1637 (2015). https://doi.org/10.1007/s11663-015-0338-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0338-6