Abstract

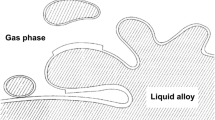

One of the most important casting defects in Al alloys is thought to be the double-oxide film defect (bifilm) which has been reported to have a deleterious effect on the reproducibility of the mechanical properties of Al castings. Previous research has suggested that the atmosphere inside such bifilms could be consumed by reaction with the surrounding melt, which might decrease the size of the defects and reduce their harmful effect on mechanical properties. In order to follow the change in the composition of the interior atmosphere of a bifilm, analog air bubbles were held inside Al alloy melts, for varying lengths of time, and subjected to stirring, followed by solidification. The bubble contents were then analyzed using a mass spectrometer to determine the changes in their compositions with time. The results suggested that initially oxygen and then nitrogen inside the bubble were consumed, and hydrogen dissolved in the melt diffused into the bubble. The consumption rates of O and N as well as the rate of H diffusion were dependent upon the type of oxide, which was dependent on the alloy composition. The reaction rates were the fastest with MgO (in an Al-5Mg alloy), slower with alumina (in commercial-purity Al alloy), and the slowest with MgAl2O4 spinel (in an Al-7Si-0.3Mg alloy). It was estimated that the times required for typical bifilm defects in the different alloys to lose their entire oxygen and nitrogen contents were about 345 seconds (~6 minutes), in the case of Al-5Mg; 538 seconds (~9 minutes), in the case of a commercial purity alloy; and 1509 seconds (~25 minutes), in the case of the Al-7Si-0.3Mg alloy (2L99) due to the different oxides that the different alloys would be expected to form.

Similar content being viewed by others

References

J. Campbell: Castings. 2nd ed., Butterworth-Heinemann, Oxford, 2003.

J. Campbell: Mater. Sci. and Tech., 2006, vol. 22: pp. 127-145.

C. Nyahumwa, N.R. Green, and J. Campbell: AFS Trans., 1998. vol. 106: pp. 215-223.

M. Aryafar, R. Raiszadeh, and A. Shalbafzadeh: J. Mater. Sci., 2010. Vol. 45, no. 11, pp. 3041-3051.

F.N. Bakhtiarani and R. Raiszadeh: Metall. Mater. Trans. B, 2011, vol. 42, pp. 331-340.

R. Raiszadeh and W.D. Griffiths: Metall. Mater. Trans. B, 2006, vol. 37, pp. 865–871.

R. Raiszadeh and W.D. Griffiths: Metall. Mater. Trans. B, 2008, vol. 39, pp. 298-303.

S. Impey, D. Stephenson, and J.R. Nicholls: Int. Conf. Microsc. Oxid., University of Cambridge, Institute of Metals, 1990, pp. 238–44.

R. Raiszadeh and W.D. Griffiths: Metall. Mater. Trans. B, 2011, vol. 42, pp. 133-143.

M. El-Sayed, H. Salem, A. Kandeil, and W.D. Griffiths: 22nd Int. Conf. Comput. Aided Prod. Eng., Edinburgh, Scotland, 2011.

M. El-Sayed, H. Salem, A. Kandeil, and W.D. Griffiths: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 1104–09.

H.Z. Ye, X.Y. Liu, and B. Luan: J. Mater. Process. Technol., 2005, vol. 166, pp. 79–85.

M.W. Chase: J. Phys. Chem. Ref. Data, 1985, vol. 14, p. 751.

W.C. Sleppy: J. Electrochem. Soc, 1961, vol. 108, no. 12, pp. 1097-1102.

J.M. Park: MRes Thesis, University of Birmingham, U.K., 2010.

Acknowledgments

The authors would like to thank Mr. Adrian Caden of the University of Birmingham; Eng. Ramy Wasfi of the American University in Cairo; and Mr. Salah Edrees of the Arab Academy for Science and Technology, Alexandria for their technical support during the laboratory work. Also, the authors wish to acknowledge the sponsorship of this study by the Arab Academy for Science and Technology, Alexandria, Egypt, and the American University in Cairo, Egypt. Finally, the authors would like to gratefully acknowledge the partial support of the EPSRC Centre for Innovative Manufacturing in Liquid Metal Engineering (grant no. EP/H026177/1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 6, 2013.

Rights and permissions

About this article

Cite this article

El-Sayed, M.A., Salem, H.A.G., Kandeil, A.Y. et al. Determination of the Lifetime of a Double-Oxide Film in Al Castings. Metall Mater Trans B 45, 1398–1406 (2014). https://doi.org/10.1007/s11663-014-0035-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0035-x