Abstract

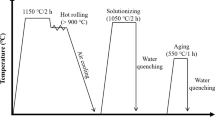

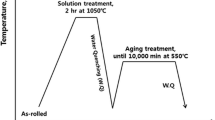

In this study, the Vickers hardnesses and room-temperature uniaxial tensile behaviors of four Fe66−x CrNiB x Si (x = 0 (0B), 0.25 (25B), 0.50 (50B), and 0.75 (75B) wt pct) advanced high-strength steels (AHSSs) in the as-hot-rolled and heat-treated (1373 K (1100 °C)/2 h + 973 K (700 °C)/20 min) conditions were investigated. Microstructural evolution after solidification, hot rolling, heat treatment, and uniaxial tensile tests of 0B, 25B, 50B, and 75B AHSSs was also characterized using field emission gun scanning electron microscopy and X-ray diffraction. The tensile behaviors of the 0B, 25B, 50B, and 75B AHSSs were manifested by an excellent combination of strength and ductility over 34.7 and 47.1 GPa pct, 36.9 and 42.3 GPa pct, 45.9 and 46.4 GPa pct, and 11.9 and 47.8 GPa pct, respectively, arising from microband-induced plasticity in the 0B, 50B, and 75B AHSSs and transformation-induced plasticity in the 25B specimens. All specimens in the as-hot-rolled and heat-treated states showed an austenitic matrix grain. Adding boron to the base alloy (0B) resulted in grain refinement, M2B dispersion, precipitation hardening, and solid solution strengthening, which led to an increase in strength. The results of the present work show promise for automotive applications that require excellent properties and reduced specific weight.

Similar content being viewed by others

References

[1] G. Jha, S. Das, S. Sinha, A. Lodh and A. Haldar: Mater. Sci. Eng. A, 2013, vol. 561, pp. 394-402.

[2] S.S. Sohn, H. Song, B.C. Suh, J.H. Kwak, B.J. Lee, N.J. Kim and S. Lee: Acta Mater., 2015, vol. 96, pp. 301-10.

[3] H. Aydin, E. Essadiqi, I.H. Jung and S. Yue: Mater. Sci. Eng. A, 2013, vol. 564, pp. 501-8.

[4] S.S. Sohn, K. Choi, J.H. Kwak, N.J. Kim and S. Lee: Acta Mater., 2014, vol. 78, pp. 181-9.

[5] H. Springer, M. Belde and D. Raabe: Mater. Des., 2016, vol. 90, pp. 1100-9.

[6] I. Gutierrez-Urrutia and D. Raabe: Scripta Mater., 2013, vol. 68, pp. 343-7.

[7] Z.B. Jiao, J.H. Luan, Z.W. Zhang, M.K. Miller, W.B. Ma and C.T. Liu: Acta Mater., 2013, vol. 61, pp. 5996-6005.

[8] C. Wang, H. Ding, M. Cai and B. Rolfe: Mater. Sci. Eng. A, 2014, vol. 610, pp. 436-44.

[9] M. Askari-Paykani, H.R. Shahverdi and R. Miresmaeili: Mater. Sci. Eng. A, 2016, vol. 668, pp. 188-200.

[10] K. Kumara, A. Pooleery, K. Madhusoodanan, R.N. Singh, J.K. Chakravartty, B.K. Dutta and R.K. Sinha: Procedia Eng., 2014, vol. 86, pp. 899-909.

[11] B.D. Cullity and S.R. Stock: Elements of X-ray Diffraction, 3 rd ed., Pearson education international, New York, 2001, pp. 347-61.

[12] Mahmohd Y. Demeri: Advanced High-Strength Steels: Science, Technology, and Application, 1st ed., ASM International, Ohio, 2013, pp. 59-65.

Steel Market Development Institute, Great design in STEEL seminar, Upper and lower body structure design strategies implements on the 2011 Chevrolet Volt. http://www.autosteel.org/~/media/Files/Autosteel/Great%20Designs%20in%20Steel/GDIS%202011/02%20-%20Steve%20McCallum%20-%20Monte%20Taylor%20-%20Volt%20Presentation.pdf

[14] I. Gutierrez-Urrutia and D. Raabe: Acta Mater., 2011, vol. 59, pp. 6449-62.

[15] J.E. Jin and Y.K. Lee: Mater. Sci. Eng. A, 2009, vol. 527, pp. 157-61.

[16] H. Ding, H. Ding, D. Song, Z. Tang, and P. Yang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 868-73.

[17] Z.H. Cai, H. Ding, X. Xue, J. Jiang, Q.B. Xin and R.D.K. Misra: Scripta Mater., 2013, vol. 68, pp. 865-8.

[18] A. Ramazani, B. Bruehl, T. Gerber, W. Bleck and U. Prahl: Mat. Des., 2014, vol. 57, pp. 479-86.

[19] C.J. Martis, S.K. Putatunda and J. Boileau: Mater. Des., 2013, vol. 46, pp. 168-74.

[20] W. Wang, M. Li, C. He, X. Wei, D. Wang and H. Du: Mater. Des., 2013, vol. 47, pp. 510-21.

[21] C.L. Lin, C.G. Chao, J.Y. Juang, J.M. Yang and T.F. Liu: J. Alloy Compd., 2014, vol. 586, pp. 616-20.

[22] A.S. Hamada, A.P. Kisko, P. Sahu and L.P. Karjalainen: Mater. Sci. Eng. A, 2015, vol. 628, pp. 154-9.

[23] A. Röttger, J. Lentz and W. Theisen: Mater. Des., 2015, vol. 88, pp. 420-9.

[24] I. Mejia, G. Altamirano, A. Bedolla-Jacuinde and J. Cabrera: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5165–76.

[25] E.J. Lavernia and T.S. Srivatsan: J. Mater. Sci., 2010, vol. 45, pp. 287–325.

[26] J.M. Vitek, A. Dasgupta adn S.A. David: Metall. Mater. Trans. A, 1983, vol. 14, pp.1833-41.

[27] J.V. Wood and R.W.K. Honeycombe: Mater. Sci. Eng. A, 1979, vol. 38, pp. 217–26.

[28] J.W. Fu, Y.S. Yang, J.J. Guo, J.C. Ma and W.H. Tong: J. Crys. Growth, 2008, vol. 311, pp. 132–6.

[29] M. Calcagnotto, Y. Adachi, D. Ponge and D. Raabe: Acta Mater., 2011, vol. 59, pp. 658-70.

[30] D.V. Porter, K.E. Easterling and M. Sherif: Phase Transformations in Metals and Alloys, 3 rd ed., CRC Press, USA, 2009, pp. 110-82.

[31] A. Gupta, A.K. Bhargava, R. Tewari and A.N. Tiwari: Metall. Mater. Trans. A, 2013, vol. 44, pp. 4248-56.

[32] P.E. Busby, M.E. Warga and C. Wells: Trans. AIME, 1953, vol. 197, pp. 1463-8.

[33] A. Wasilkowska, P. Tsipouridis, E.A. Werner, A. Pichler and S. Traint: J. Mater. Process Tech., 2014, vol. 58, pp.633-6.

[34] J. Galán, L. Samek, P. Verleysen, K. Verbeken and Y. Houbaert: Revista de Metal, 2012, vol. 48, pp. 118-31.

[35] J. Mahieu, J. Maki, B.C. De Cooman and S. Claessens: Metall. Mater. Trans. A, 2002, vol. 33, pp. 2573-80.

[36] K. Sugimoto, M. Misu, M. Kobayashi and H. Shirasawa: ISIJ Int., 1993, vol. 33, pp. 775-82.

[37] S.O. Kruijver, L. Zhao, J. Sietsma, S.E. Offerman, N.H.V. Dijk, E.M. Lauridsen, L. Margulies, S. Grigull, H.F. Poulsen and S. van der Zwaag: J. Phys. IV, 2003, vol. 104, pp. 499–502.

[38] D.A. Hughes: Acta Metall. Mater., 1993, vol. 41, pp. 1421-30.

[39] D. Kuhlmann-Wilsdorf: Mater. Sci. Eng. A, 1989, vol. 113, pp.1-41.

[40] J. Doo Yoo and K.T. Park: Mater. Sci. Eng. A, 2008, vol. 496, pp. 417-24.

[41] N. Hansen: Scripta Mater., 2004, vol. 51, pp. 801-6.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 26, 2016.

Rights and permissions

About this article

Cite this article

Askari-Paykani, M., Shahverdi, H.R. & Miresmaeili, R. Effect of Boron Addition on Microstructural Evolution and Room-Temperature Mechanical Properties of Novel Fe66−x CrNiB x Si (x = 0, 0.25, 0.50 and 0.75 Wt Pct) Advanced High-Strength Steels. Metall Mater Trans A 47, 5423–5437 (2016). https://doi.org/10.1007/s11661-016-3713-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3713-2