Abstract

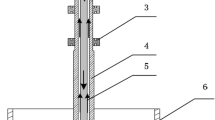

With the rapid development of the aviation industry, the turbine blade, a critical component of the aeronautical engine, has come to be widely produced by liquid-metal cooling (LMC) process. A temperature- and time-dependent heat transfer coefficient was used to represent the heat convection between the shell and the cooling liquid, and an improved Monte Carlo ray-tracing approach was adopted to handle the boundary of radiation heat transfer. Unstructured mesh was used to fit the irregular shell boundary, and the heat transfer model of directional solidification by LMC process based on finite element method (FEM) was established. The concept of local matrix was here proposed to guarantee computational efficiency. The pouring experiments of directional solidification by LMC process were carried out, then simulation and experimental results were compared here. The accuracy of the heat transfer model was validated by the cooling curves and grain morphology, and the maximum relative error between simulation and experimental cooling curve was 2 pct. The withdrawal rate showed an important influence on the shape of solidification interface, and stray grain is liable to be generated on the bottom of platform at an excessive withdrawal rate.

Similar content being viewed by others

References

G. A. Chadwick: Corros. Eng. Sci. Technol., 1984, vol. 19, no. 4, pp. 154–55.

D. X. Ma: Acta. Metall. Sin., 2015, vol. 51, no. 10, pp. 1179–90.

H. Fu, X. Geng: Sci. Technol. Adv. Mat., 2001, vol. 2, no. 1, pp. 197–204.

N. Tang, Y. L. Wang, Q. Y. Xu, X. H. Zhao and B. C. Liu: Acta. Metall. Sin., 2015, vol. 51, no. 4, pp. 499–512.

C. H. Lund, J. Hockin: Superalloys, Wiley, New York, 1972, pp. 403–25

M. Konter, M. Thumann: J. Mater. Process. Technol., 2001, vol. 117, no. 3, pp. 386–90.

J. Zhang, T. W. Huang, L. Liu and H. Z. Fu: Acta. Metall. Sin., 2015, vol. 51, no. 10, pp. 1163–78.

A. F. Giamei, J. G. Tschinkel: Metall. Mater. Trans. A, 1976, vol. 7A, no. 9, pp. 1427–34.

J. H. Liu, L. Liu, T. W. Huang, B. M. Ge, J. Zhang, H. Z. Fu, B. Yu, G. Q. Su, P. H. Wang and X. F. Liu: Foundry, 2010, vol. 59, no. 8, pp. 822–25.

A. J. Elliott, S. Tin, W. T. King, S. C. Huang, M. F. X. Gigliotti and T. M. Pollock: Metall. Mater. Trans. A, 2004, vol. 35A, no. 10, pp. 3221–31.

A. J. Elliott, G. B. Karney, M. F. X. Gigliotti and T. M. Pollock: Superalloys, TMS, Warrendale, 2004, pp. 421–30

J. Zhang, L. H. Lou: J. Mater. Sci. Technol., 2007, vol. 23, no. 3, pp. 289–300.

G. Liu, L. Liu, X. B. Zhao, W. G. Zhang, T. Jin, J. Zhang and H. Z. Fu: Acta. Metall. Sin., 2010, vol. 46, no. 1, pp. 77–83.

C. L. Brundidge, D. Vandrasek, B. Wang and T. M. Pollock: Metall. Mater. Trans. A, 2012, vol. 43A, no. 3, pp. 965-76.

J. D. Miller, T. M. Pollock: Metall. Mater. Trans. A, 2012, vol. 43A, no. 7, pp. 2414–25.

R. E. Napolitano, R. J. Schaefer: J. Mater. Sci., 2000, vol. 35, no. 7, pp. 1641–59.

A. Kermanpur, N. Varahram, P. Davami and M. Rappaz: Metall. Mater. Trans. B, 2000, vol. 31, no. 6, pp. 1293–304.

A. J. Elliott, T. M. Pollock: Metall. Mater. Trans. A, 2007, vol. 38A, no. 4, pp. 871–82.

Y. Z. Lu, D. W. Wang, J. Zhang and L. H. Lou: Foundry, 2009, vol. 58, no. 3, pp. 245–48.

Y. Z. Lu, H. J. Xi, J. Shen, W. Zheng, G. Xie, L. H. Lou and J. Zhang: Acta. Metall. Sin., 2015, vol. 51, no. 5, pp. 603–11.

X. W. Yan, N. Tang, X. F. Liu, G. Y. Shui, Q. Y. Xu and B. C. Liu: Acta. Metall. Sin., 2015, vol. 51, no. 10, pp. 1288–96.

A. R. Mitchell, D. F. Griffiths: The Finite Difference Method in Partial Differential Equations, Wiley, Hoboken, 1980.

H. K. Versteeg, W. Malalasekera: An Introduction to Computational Fluid Dynamics: The Finite Volume Method, Pearson Education, New York, 2007.

G. Dhatt, E. Lefrançois and G. Touzot: Finite Element Method, Wiley, Hoboken, 2012.

G. Vladimir: Materials in technology, 2009, vol. 43, no. 5, pp. 233–37.

T. Chen, D. M. Liao and J. X. Zhou: Materials Science Forum, 2013, vol. 762, pp. 224–29.

S. Perron, S. Boivin and J. Hérard: Comput. Fluids, 2004, vol. 33, no. 10, pp. 1305–33.

W. Gao, Y. L. Duan and R. X. Liu: J. Hydrodyn., 2009, vol. 21, no. 2, pp. 201–11.

T. Chen: PhD Thesis, Huazhong University of Science and Technology, 2013.

L. Cao, D. M. Liao, L. M. Cao, H. P. Gu, T. Chen and S. Y. Pang: Foundry, 2014, vol. 63, no. 12, pp. 1235-40.

X. C. Wang: Finite Element Method, Tsinghua University Press, Beijing, 2003.

K. Cui, Q. Y. Xu, J. Yu, B. C. Liu, A. Kimatsuka, Y. Kuroki and F. Yokoyama: Acta. Metall. Sin., 2007, vol. 43, no. 5, pp. 465–71.

J. Yu, Q. Y. Xu, J. R. Li, H. L. Yuan, S. Z. Liu and B. C. Liu: Acta. Metall. Sin., 2007, vol. 43, no. 10, pp. 1113–20.

D. Pan, Q. Y. Xu and B. C. Liu: Acta. Metall. Sin., 2010, vol. 46, no. 3, pp. 294–303.

S. S. Kutateladze, V. M. Borishanskii: Liquid-Metal Heat Transfer Media, Consultants Bureau, New York, 1959.

X. F. Sun, T. Jin, Y. Z. Zhou and Z. Q. Hu: Mater. China, 2012, vol. 31, no. 12, pp. 1–11.

Acknowledgments

This research is financially supported by the Program for New Century Excellent Talents in University (No. NCET-13-0229, NCET-09-0396), the National Science & Technology Key Projects of Numerical Control (No. 2012ZX04010-031, 2012ZX0412-011), and the National High Technology Research and Development Program (“863” Program) of China (No. 2013031003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 20, 2016

Rights and permissions

About this article

Cite this article

Cao, L., Liao, D., Lu, Y. et al. Heat Transfer Model of Directional Solidification by LMC Process for Superalloy Casting Based on Finite Element Method. Metall Mater Trans A 47, 4640–4647 (2016). https://doi.org/10.1007/s11661-016-3619-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3619-z