Abstract

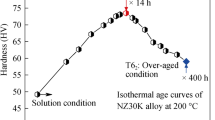

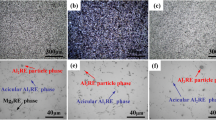

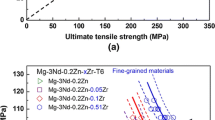

This paper investigates the fatigue properties and deformation behavior of a newly developed Mg-2.96Nd-0.21Zn-0.39Zr magnesium alloy wheel in both as-cast and T6 conditions. Compared with the as-cast alloy, the T6-treated alloy shows a significant increase in fatigue strength and cyclic stress amplitude. This is believed to be attributed to the change of defect type from porosity to oxides and the increased matrix strength in the T6 (peak-aged) condition. For the as-cast alloy wheel, fatigue failure mainly originated from the cast defects including porosity, oxide film, and inclusion at or near the sample surface. In the T6-treated alloy, however, oxides and inclusions or slip bands initiate the fatigue cracks. Solution treatment appears to reduce or eliminate the shrinkage porosity because of grain growth and dissolution of as-cast eutectic phases in the grain boundaries. The cyclic stress amplitude of the as-cast alloy increases with increasing the number of cycles, while the T6-treated alloy shows cyclic softening after the stress reaches a maximum value. The Coffin–Manson law and Basquin equation can be used to evaluate the life of low cycle fatigue. The developed long crack model and multi-scale fatigue (MSF) models can be used to predict high-cycle fatigue life of the Mg-2.96Nd-0.21Zn-0.39Zr alloys with or without casting defects.

Similar content being viewed by others

References

A.I. Taub, P.E. Krajewski, A.A. Luo, and J.N. Owens: JOM, 2007, vol. 59, pp. 48–57.

A.A. Luo: Int. Mater. Reviews, 2004, vol. 49, pp. 13–30.

H. Mayer, M. Papakyriacou, B. Zettl, and S.E. Stanzl-Tschegg: Int. J. Fatigue, 2003, vol. 25, pp. 245–56.

M.F. Horstemeyer, N. Yang, K. Gall, D.L. McDowell, J. Fan, and P.M. Gullett: Acta Mater., 2004, vol. 52, pp. 1327–36.

P.H. Fu, L.M. Peng, H.Y. Jiang, J.W. Chang, and C.Q. Zhai: Mater. Sci. Eng. A, 2008, vol. 486, pp. 183–92.

P.H. Fu, L.M. Peng, H.Y. Jiang, L. Ma, and C.Q. Zhai: Mater. Sci. Eng. A, 2008, vol. 496, pp. 177–88.

Z.M. Li, A.A. Luo, Q.G. Wang, L.M. Peng, P.H. Fu, and G.H. Wu: Mater. Sci. Eng. A, 2013, vol. 564, pp. 450–60.

Z.M. Li, Q.G. Wang, A.A. Luo, P.H. Fu, L.M. Peng, Y.X. Wang, and G.H. Wu: Metall. Mater. Trans. A, 2013, vol. 44, pp. 5202–15.

L.M. Peng, P.H. Fu, Z.M. Li, H.Y. Yue, D.Q. Li, and Y.X. Wang: Mater. Sci. Eng. A, 2014, vol. 611, pp. 170–6.

L.M. Peng, P.H. Fu, Z.M. Li, Y.X. Wang, and H.Y. Jiang: J. Mater. Sci., 2014, vol. 49, pp. 7105–15.

Z.M. Li, Q.G. Wang, A.A. Luo, P.H. Fu, and L.M. Peng: Inter. J. Fatigue, 2015, vol. 80, pp. 468–76.

J.W. Chang, L.M. Peng, X.W. Guo, A. Atrens, and P.H. Fu: J. Appl. Electrochem., 2008, vol. 38, pp. 207–14.

J.W. Chang, X.W. Guo, P.H. Fu, L.M. Peng, and W.J. Ding: Electrochim. Acta, 2007, vol. 52, pp. 3160–67.

J.W. Chang, P.H. Fu, X.W. Guo, and L.M. Peng: Corros. Sci., 2007, vol. 49, pp. 2612–27.

Z.M. Li, Q.G. Wang, A.A. Luo, L.M. Peng, P.H. Fu, and Y.X. Wang: Mater. Sci. Eng., 2013, vol. 582, pp. 170–7.

S. Begum, D.L. Chen, S. Xu, and A.A. Luo: Metall. Mater. Trans. A, 2008, vol. 39, pp. 3014–26.

S. Begum, D.L. Chen, S. Xu, and A.A. Luo: Int. J. Fatigue, 2009, vol. 31, pp. 726–35.

Q.Z. Li, Q Yu, J.X. Zhang, and Y.Y. Jiang: Scripta Mater., 2010, vol. 62, pp. 778–81.

K. Gall, M.F. Horstemeyer, B.W. Degner, D.L. McDowell, and J. Fan: Int. J. Fract., 2001, vol. 108, pp. 207–33.

D.K. Xu, L. Liu, Y.B. Xu, and E.H. Han: Scripta Mater., 2007, vol. 56, pp. 1–4.

Z.M. Li, P.H. Fu, L.M. Peng, Y.X. Wang, H.Y. Jiang, and G.H. Wu: Mater. Sci. Eng. A, 2013, vol. 579, pp. 170–9.

Q.G. Wang, C.J. Davidson, J.R. Griffiths, and P.N. Crepeau: Metall. Mater. Trans. B, 2006, vol. 44, pp. 887–95.

Q.G. Wang and P.E. Jones: Metall. Mater. Trans. B, 2007, vol. 38, pp. 615–21.

D.K. Xu, L. Liu, B.Y. Xu, and E.H. Han: Acta Mater., 2008, vol. 56, pp. 985–94.

Q.G. Wang, D. Apelian, and D.A. Lados: J. Light Met., 2001, vol. 1, pp. 73–84.

P.S. De, R.S. Mishra, and C.B. Smith: Scripta Mater., 2009, vol. 60, pp. 500–3.

Z.M. Li, P.H. Fu, L.M. Peng, E.P. Becker, and G.H. Wu: Mater. Sci. Eng. A, 2013, vol. 565, pp. 250–7.

Q.G. Wang, D. Apelian, and D.A. Lados: J. Light Met., 2001, vol. 1, pp. 85–97.

R.A. Siddiqui, S.A. Abdul-Wahab, and T. Pervez: Mater. Des., 2008, vol. 29, pp. 70–9.

M.E. Burba, M.J. Caton, S.K. Jha, and C.J. Szczepanski: Metal. Mater. Trans A, 2013, vol. 44, pp. 4954–67.

C.J. Davidson, J.R. Griffiths, and A.S. Machin: Fatigue Fract. Eng. Mater. Struct., 2002, vol. 25, pp. 223–30.

Q.G. Wang and P. Jones: SAE Int. J. Mater. Manuf., 2011, vol. 4, pp. 289–97.

Z.M. Li, Q.G. Wang, A.A. Luo, L.M. Peng and P. Zhang: Mater. Sci. Eng. A, 2015, vol. 647, pp. 113–26.

S.M. He, X.Q. Zeng, L.M. Peng, X. Gao, J.F. Nie, and W.J. Ding: J. Alloys Comp., 2007, vol. 427, pp. 316–23.

S.L. Sin, A. Elsayed, and C. Ravindran: Int. Mater. Rev., 2013, vol. 58, pp. 419–36.

A. Sarkar, B.K. Kumawat, and J.K. Chakravartty: J. Nucl. Mater., 2015, vol. 462, pp. 273–9.

N. Khutia, P.P. Dey, S.K. Paul, and S. Tarafder: Mech. Mater., 2013, vol. 65, pp. 88–102.

Q.G. Wang: Metall. Mater. Trans. A, 2003, vol. 34, pp. 2887–99.

F. Thomas, U. Noster, B. Scholtes, and P. Uggowitzer: Proceedings of the 2nd International Light Metals Technology Conference, Switzerland, 2005.

S.M. Yin, F. Yang, X.M. Yang, S.D. Wu, S.X. Li, and G.Y. Li: Mater. Sci. Eng. A, 2008, vol. 494, pp. 397–400.

L. Wu, A. Jain, D.W. Brown, G.M. Stoica, S.R. Agnew, B. Clausen, D.E. Fielden, and P.K. Liaw: Acta Mater., 2008, vol. 56, pp. 68–95.

X.Y. Lou, M. Li, P.K. Boger, S.R. Agnew, and R.H. Wagoner: Int. J. Plasti., 2007, vol. 23, pp. 44–86.

Y.J. Wu, R. Zhu, J.T. Wang, and W.Q. Ji: Scripta Mater., 2010, vol. 63, pp. 1077–80.

P.H. Fu, L.M. Peng, J.F. Nie, H.Y. Jiang, L. Ma, and L. Bourgeois: Mater. Sci. Forum., 2011, vol. 690, pp. 230–33.

C.H. Cáceres and B.I. Selling: Mater Sci Eng A, 1996, vol. 220, pp. 109–16.

Q.G. Wang: Metall. Mater. Trans. A, 2004, vol. 35, pp. 2707–18.

Q.G. Wang, C.H. Cáceres, and J.R. Griffiths: Metall. Mater. Trans. A, 2003, vol. 34, pp. 2901–12.

S.E. Harvey, P.G. Marsh, and W.W. Gerberich: Acta Metall. Mater., 1994, vol. 42, pp. 3493–502.

J. Man, M. Petrenec, K. Obrtlík, and J. Polák: Acta Mater., 2004, vol. 52, pp. 5551–61.

J. Man, K. Obrtlík, C. Blochwitz, and J. Polák: Acta Mater., 2002, vol. 50, pp. 3767–80.

J. Polák, J. Man, T. Vystavel, and M. Petrenec: Mater. Sci. Eng. A, 2009, vol. 517, pp. 204–11.

Acknowledgments

This work was carried out as a collaborative research project supported by General Motors and Shanghai Jiao Tong University. This work was also supported by the Project Funded by China Postdoctoral Science Foundation (2015M571562). The authors are grateful to Drs. Anil Sachdev and Yucong Wang (GM) and Professor Wengjiang Ding (SJTU) for their helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 8, 2015.

Rights and permissions

About this article

Cite this article

Li, Z., Luo, A.A., Wang, Q. et al. Fatigue Properties of Cast Magnesium Wheels. Metall Mater Trans A 47, 4239–4257 (2016). https://doi.org/10.1007/s11661-016-3550-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3550-3