Abstract

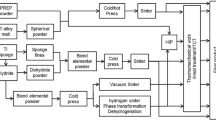

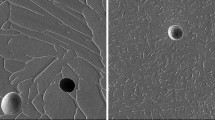

Recently, manufacturing of titanium by sintering and dehydrogenation of hydride powders has generated a great deal of interest. An overarching concern regarding powder metallurgy (PM) titanium is that critical mechanical properties, especially the high-cycle fatigue strength, are lower than those of wrought titanium alloys. It is demonstrated here that PM Ti-6Al-4V alloy with mechanical properties comparable (in fatigue strength) and exceeding (in tensile properties) those of wrought Ti-6Al-4V can be produced from titanium hydride powder, through the hydrogen sintering and phase transformation process. Tensile and fatigue behavior, as well as fatigue fracture mechanisms, have been investigated under three processing conditions. It is shown that a reduction in the size of extreme-sized pores by changing the hydride particle size distribution can lead to improved fatigue strength. Further densification by pneumatic isostatic forging leads to a fatigue strength of ~550 MPa, comparable to the best of PM Ti-6Al-4V alloys prepared by other methods and approaching the fatigue strengths of wrought Ti-6Al-4V alloys. The microstructural factors that limit fatigue strength in PM titanium have been investigated, and pathways to achieve greater fatigue strengths in PM Ti-6Al-4V alloys have been identified.

Similar content being viewed by others

References

T. Fujita, A. Ogawa, C. Ouchi, and H. Tajima: Mater. Sci. Eng. A, 1996, vol. 213, pp. 148-53.

P.J. Anderson, V.M. Svoyatytsky, F.H. Froes, Y. Mahajan, and D. Eylon: Modern Develop. Powder Metall., 1981, vol. 13, pp. 537-49.

D. Eylon, R.G. Vogt, and F.H. Froes: Modern Develop. Powder Metall., 1985, vol. 16, pp. 563-75.

Z.Z. Fang, P. Sun, and H. Wang: Adv. Eng. Mater., 2012, vol. 14(6), pp. 383-387.

Z.Z. Fang and P. Sun: Key Eng. Mater., 2012, vol. 520, pp. 15-23.

M. Hagiwara, and S. Emura: Mater. Sci. Eng. A, 2003, vol. 352, pp. 85-92.

M. Hagiwara, Y. Kaieda, Y. Kawabe, and S. Miura: ISIJ Int., 1991, vol. 31, pp. 922-90.

D. Eylon: Metall. Trans. A, 1979, vol. 10, pp. 311-17.

F.H. Froes, S.J. Mashl, V.S. Moxson, J.C. Hebeisen, and V.A. Duz: JOM, 2004, vol. 56(11), pp. 46-48.

P. Sun, Z. Z. Fang, and M. Koopman: Adv. Eng. Mater., 2013, vol. 15(10), pp. 1007-13.

P. Sun, Z. Z. Fang, M. Koopman, J. Paramore, K.S. RaviChandran, Y. Ren, and J. Lu: Acta Mater., 2015, vol. 84, pp. 29-41.

P. Sun, Z.Z. Fang, M. Koopman, Y. Xia, J. Paramore, K.S. RaviChandran, Y. Ren, and J. Lu: Metall. Mater. Trans. A, 2015, vol. 46, pp. 1-15.

W.R. Kerr, P.R. Smith, M.E. Rosenblum, F.J. Gurney, Y.R. Mahajan, and L.R. Bidwell: Titanium’80, Science and Technology, Proceedings of the 4th International Conference on Titanium., Metall. Soc. of AIME, Kyoto, Japan, 1980, pp. 2477–86.

W.R. Kerr: Metall. Mater. Trans. A, 1985, vol. 16A, pp. 1077-87.

J. Qazi, J. Rahim, F. Froes, O. Senkov, and A. Genc: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2453-63.

D.H. Kohn and P. Ducheyne: J. Mater. Sci., 1991, vol. 26, pp. 534-44.

Y. Yan, G.L. Nash, and P. Nash: Int. J. Fatigue, 2013, vol. 55, pp. 81-91.

V.S. Moxson, P. Sjoblom, and M.J. Trzcinski, Adv. Powder Metall., 1992, vol. 6, pp. 125-40.

A. Atrens, W. Hoffelner, T.W. Duerig, and J.E. Allison: Scripta Metall., 1983, vol. 17, pp. 601-06.

Y. Furuya and E. Takeuchi: Mater. Sci. Eng. A, 2014, vol. 598, pp. 135-40.

X. Liu, C. Sun, and Y. Hong, Mater. Sci. Eng. A, 2015, vol. 622, pp. 228-35.

K.J. Miller: Mater. Sci. Tech., 1993, vol. 9, pp. 453-62.

A. De Bussac: Fatigue Fract. Engng. Mater. Struct., 1994, vol. 17, pp. 1319-25.

F. Cao, P. Kumar, M. Koopman, C. Lin, Z.Z. Fang, and K.S. Ravi Chandran: Mater. Sci. Eng. A, 2015, vol. 630, pp. 139-45.

J.P. Herteman, D. Eylon, and F.H. Froes: Powder Metall. Int., 1985, vol. 17, pp. 116-19.

F.H. Froes, D. Eylon, and S.W. Schwenker: Progress in Powder Metall., 1986, vol. 41, pp. 519-530.

G. Wirth, K. J. Grundhoff, and W. Smarsly: SAMPE Quarterly, 1986, vol. 17(2), pp. 34-39.

Acknowledgments

The authors gratefully acknowledge the funding support from the US Department of Energy, Innovative Manufacturing Initiative (DEEE0005761), through the Advanced Manufacturing Office and the Office of Energy Efficiency and Renewable Energy.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 12, 2015.

Rights and permissions

About this article

Cite this article

Cao, F., Ravi Chandran, K.S., Kumar, P. et al. New Powder Metallurgical Approach to Achieve High Fatigue Strength in Ti-6Al-4V Alloy. Metall Mater Trans A 47, 2335–2345 (2016). https://doi.org/10.1007/s11661-016-3409-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3409-7