Abstract

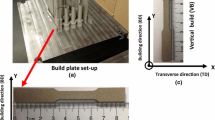

Two sets of “theta”-shaped specimens were additively manufactured with Inconel 718 powders using an electron beam melting technique with two distinct scan strategies. Light optical microscopy, mechanical testing coupled with a digital image correlation (DIC) technique, finite element modeling, and neutron diffraction with in situ loading characterizations were conducted. The cross-members of the specimens were the focus. Light optical micrographs revealed that different microstructures were formed with different scan strategies. Ex situ mechanical testing revealed each build to be stable under load until ductility was observed on the cross-members before failure. The elastic moduli were determined by forming a correlation between the elastic tensile stresses determined from FEM, and the elastic strains obtained from DIC. The lattice strains were mapped with neutron diffraction during in situ elastic loading; and a good correlation between the average axial lattice strains on the cross-member and those determined from the DIC analysis was found. The spatially resolved stresses in the elastic deformation regime are derived from the lattice strains and increased with applied load, showing a consistent distribution along the cross-member.

Similar content being viewed by others

Notes

Correlated Solutions VIC-3D™ ⊗image analysis software, Correlated Solutions, Inc., Columbia, SC, USA, 2010.

References

C.A. Brice, W.H. Hofmeister, Metall Mater Trans A, 44A (2013) 5147-5153.

R.R. Dehoff, S.S. Babu, Acta Mater, 58 (2010) 4305-4315.

W.J. Sames, K.A. Unocic, R.R. Dehoff, T. Lolla, S.S. Babu, J Mater Res, 29 (2014) 1920-1930.

W.E. Frazier, J Mater Eng Perform, 23 (2014) 1917-1928.

C.K. Chuma, K.F. Leong, C.S. Lim, Rapid Prototyping: Principles and Applications, 2nd ed., World Scientific, Singapore, 2003.

S.S. Al-Bermani, M.L. Blackmore, W. Zhang, I. Todd, Metall Mater Trans A, 41A (2010) 3422-3434.

S.M. Gaytan, L.E. Murr, F. Medina, E. Martinez, M.I. Lopez, R.B. Wicker, Mater Technol, 24 (2009) 180-190.

L.E. Murr, E.V. Esquivel, S.A. Quinones, S.M. Gaytan, M.I. Lopez, E.Y. Martinez, F. Medina, D.H. Hernandez, E. Martinez, J.L. Martinez, S.W. Stafford, D.K. Brown, T. Hoppe, W. Meyers, U. Lindhe, R.B. Wicker, Materials Charact, 60 (2009) 96-105.

R. Dehoff, C. Duty, W. Peter, Y. Yamamoto, W. Chen, C. Blue, C. Tallman, Adv Mater Process, 171 (2013) 19-22.

Y.C. Zhang, Z.G. Li, P.L. Nie, Y.X. Wu, Metall Mater Trans A, 44A (2013) 708-716.

A. Strondl, S. Milenkovic, A. Schneider, U. Klement, G. Frommeyer, Adv Eng Mater, 14 (2012) 427-438.

T. Vilaro, C. Colin, J.D. Bartout, L. Naze, M. Sennour, Mater Sci Eng A-Struct, 534 (2012) 446-451.

H. Qi, M. Azer, A. Ritter, Metall Mater Trans A, 40A (2009) 2410-2422.

A. Strondl, R. Fischer, G. Frommeyer, A. Schneider, Mater Sci Eng A-Struct, 480 (2008) 138-147.

P.L. Blackwell, J Mater Process Technol, 170 (2005) 240-246.

A. Strondl, M. Palm, J. Gnauk, G. Frommeyer, Mater Sci Tech, 27 (2011) 876-83.

Y. Tian, D. McAllister, H. Colijn, M. Mills, D. Farson, M. Nordin, S. Babu, Metall Mater Trans A, 45A (2014) 4470-4482.

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, F. Medina, Acta Mater, 60 (2012) 2229-2239.

K.N. Amato, J. Hernandez, L.E. Murr, E. Martinez, S.M. Gaytan, P.W. Shindo, S. Collins, J Mater Sci Res, 1 (2012) 3-41.

C. Radhakrishna, K.P. Rao, J Mater Sci, 32 (1997) 1977-1984.

A. Devaux, L. Naze, R. Molins, A. Pineau, A. Organista, J.Y. Guedou, J.F. Uginet, P. Heritier, Mater Sci Eng A-Struct, 486 (2008) 117-122.

L.E. Murr, E. Martinez, S.M. Gaytan, D.A. Ramirez, B.I. Machado, P.W. Shindo, J.L. Martinez, F. Medina, J. Wooten, D. Ciscel, U. Ackelid, R.B. Wicker, Metall Mater Trans A, 42A (2011) 3491-3508.

L. Sochalski-Kolbus, E. Payzant, P. Cornwell, T. Watkins, S. Babu, R. Dehoff, M. Lorenz, O. Ovchinnikova, C. Duty: Metall. Mater. Trans. A, vol. 46A, (2015) pp. 1419–32.

L.E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, K.N. Amato, P.W. Shindo, F.R. Medina, R.B. Wicker, J Mater Sci Technol, 28 (2012) 1-14.

D. Cormier, A. Harrysson, H. West, Rapid Prototyping J, 10 (2004) 35-41.

P. Rangaswamy, M.L. Griffith, M.B. Prime, T.M. Holden, R.B. Rogge, J.M. Edwards, R.J. Sebring, Mater Sci Eng A-Struct, 399 (2005) 72-83.

A.J. Durelli, S. Morse, V. Parks, Materials Res Standard, 2 (1962) 114-117.

G.D. Quinn: in Fractography of Advanced Ceramics III, J. Dusza, R. Danzer, R. Morrell, G.D. Quinn, eds., 2009, pp. 201–208.

R. Dehoff, M. Kirka, W. Sames, H. Bilheux, A. Tremsin, L. Lowe, S. Babu, Mater Sci Tech, 31 (2015) 931-938.

M. Larsson: US Patent #US 7713454 B2, 11 May 2010.

ABAQUS (2011) “ABAQUS Documentation”, Dassault Systèmes, Providence, RI, USA.

H. Si: ACM Trans. Math. Softw., 2015, vol. 41(2), art. no. 11.

Technical Bulletin: “Inconel Alloy 718”, Special Metals Corporation, 2007.

B. Baufeld, J Mater Eng Perform, 21 (2012) 1416-1421.

R.K. Bird and J. Hibberd: NASA Technical Memorandum Paper No. TM-2009-215929, 2009.

J. Repper, P. Link, M. Hofmann, C. Krempaszky, W. Petry, E. Werner, Appl Phys A-Mater, 99 (2010) 565-569.

K. An, W.B. Bailey, S.O. Craig, H. Choo, C.R. Hubbard, D.L. Erdman III, J J Neutron Res, 15 (2007) 207-213.

M.T. Hutchings, P.J. Withers, T.M. Holden, T. Lorentzen, Introduction to the characterization of residual stress by neutron diffraction, Taylor and Francis, Boca Raton, FL, 2005.

Acknowledgments

This research was sponsored by the Laboratory Directed Research and Development Program of Oak Ridge National Laboratory, managed by UT-Battelle, LLC, for the U. S. Department of Energy. Research at MDF was sponsored by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office, under contract DE-AC05-00OR22725 with UT-Battelle, LLC. Research at ORNL’s High Flux Isotope Reactor was sponsored by the Scientific User Facilities Division, Office of Basic Energy Sciences, U.S. Department of Energy. EC and TRW would like to thank Dr. E. Andrew Payzant for the neutron beam time, Mr. Christopher O. Stevens for his help with the ex situ mechanical testing, and Mr. Tom Geer for optical microscopy measurements. Further, the authors gratefully acknowledge Dr. Donald L. Erdman III, Mr. Stephen Kulan, and Dr. Ke An for their timely help with the load frame during our measurements at HFIR. EC would also like to thank Dr. Michael M. Kirka for his valuable input and Mr. Cemal Kizildag for his assistance with image processing.

Author information

Authors and Affiliations

Corresponding author

Additional information

This manuscript has been authored by UT-Battelle, LLC under Contract No. DE-AC05-00OR22725 with the U.S. Department of Energy. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a nonexclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. The Department of Energy will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan (http://energy.gov/downloads/doe-public-access-plan).

Manuscript submitted July 3, 2015.

Rights and permissions

About this article

Cite this article

Cakmak, E., Watkins, T.R., Bunn, J.R. et al. Mechanical Characterization of an Additively Manufactured Inconel 718 Theta-Shaped Specimen. Metall Mater Trans A 47, 971–980 (2016). https://doi.org/10.1007/s11661-015-3186-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-3186-8