Abstract

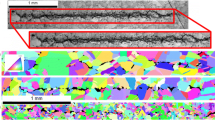

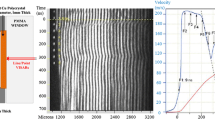

Local microstructural weak links for spall damage were investigated using three-dimensional (3-D) characterization in multicrystalline copper samples (grain size ≈ 450 µm) shocked with laser-driven plates at low pressures (2 to 4 GPa). The thickness of samples and flyer plates, approximately 1000 and 500 µm respectively, led to short pressure pulses that allowed isolating microstructure effects on local damage characteristics. Electron Backscattering Diffraction and optical microscopy were used to relate the presence, size, and shape of porosity to local microstructure. The experiments were complemented with 3-D finite element simulations of individual grain boundaries (GBs) that resulted in large damage volumes using crystal plasticity coupled with a void nucleation and growth model. Results from analysis of these damage sites show that the presence of a GB-affected zone, where strain concentration occurs next to a GB, correlates strongly with damage localization at these sites, most likely due to the inability of maintaining strain compatibility across these interfaces, with additional effects due to the inclination of the GB with respect to the shock. Results indicate that strain compatibility plays an important role on intergranular spall damage in metallic materials.

Similar content being viewed by others

References

Meyers, M.A. and Aimone, C.T.: Prog. Mater. Sci., 1983. 28: p. 1–96.

Meyers, M.A., Dynamic Behavior of Materials. 1994, New York: John Wiley & Sons, Inc.

Minich, R.W., Cazamias, J.U., Kumar, M., and Schwartz, A.J.: Metall. Mater. Trans. A, 2004. 35A: p. 2663–73.

Chen, X., Asay, J.R., Dwivedi, S.K., and Field, D.P.: J. Appl. Phys., 2006. 99: 023528

Wayne, L., Krishnan, K., DiGiacomo, S., Kovvali, N., Peralta, P., Luo, S.-N., Greenfield, S., Byler, D., Paisley, D., McClellan, K.J., Koskelo, A., and Dickerson, R.: Scripta mater., 2010. 63: p. 1065–68.

Peralta, P., DiGiacomo, S., Hashemian, S., Luo, S.-N., Paisley, D.L., Dickerson, R., Loomis, E., Byler, D., McClellan, K.J., and D’Armas, H.: Int. J. Damage Mech., 2009. 18: p. 393-413.

Escobedo, J.P., Dennis-Koller, D., Cerreta, E.K., Patterson, B.M., Bronkhorst, C.A., Hansen, B.L., Tonks, D., and Lebensohn, R.A.: J. Appl. Phys., 2011. 110(3): p. 033513.

Cerreta, E.K., Escobedo, J.P., Perez-Bergquist, A., Koller, D.D., Trujillo, C.P., Gray Iii, G.T., Brandl, C., and Germann, T.C.: Scripta Mater., 2012. 66(9): p. 638–41.

Luo, S.-N., Germann, T.C., Tonks, D.L., and An, Q.: J. Appl. Phys., 2010. 108(9): p. 093526.

Han, W., An, Q., Luo, S., Germann, T., Tonks, D., and Goddard, W.: Phys. Rev. B, 2012. 85(2): 024107

Fensin, S.J., Valone, S.M., Cerreta, E.K., and Gray, G.T.: J. Appl. Phys., 2012. 112(8): p. 083529.

Fensin, S.J., Escobedo-Diaz, J.P., Brandl, C., Cerreta, E.K., Gray Iii, G.T., Germann, T.C., and Valone, S.M.: Acta Mater., 2014. 64(0): p. 113-122.

Sutton, A.P. and Ballufi, R.W., Interfaces in Crystalline Materials. 1995, New York: Oxford University Press.

Cochran, S. and Banner, D.: J. Appl. Phys., 1977. 48: 2729

Follansbee, P.S. and Kocks, U.F.: Acta Metall., 1988. 36: p. 81-93.

Steinberg, D.J., Cochran, S.G. and Guinan, M.W.: J. Appl. Phys., 1980. 51(3): p. 1498–504.

Zerilli, F.J. and Armstrong, R.W.: J. Appl. Phys, 1987. 61: p. 1816–25.

Gurson, A.L.: J. Eng. Mater. Technol., 1977. 99: p. 2-15.

Tvergaard, V. and Needleman, A.: Acta Metall., 1984. 32: p. 157–69.

Chaboche, J.L.: J.Appl. Mech., 1988. 55: p. 59-64.

Lemaitre, J. and Desmorat, R., Engineering Damage Mechanics: Ductile, Creep, Fatigue and Brittle Failures. 2005, Berlin: Springer-Verlag.

Czarnota, C., Jacques, N., Mercier, S., and Molinari, A.: J. Mech. Phys. Sol., 2008. 56: p. 1624–50.

Wright, T.W. and Ramesh, K.T.: J. Mech. Phys. Sol., 2008. 56: p. 336–59.

Becker, R.: Int. J. Plast., 2004. 20: p. 1983-2006.

Lukyanov, A.A.: Int. J. Plast., 2008. 24:140–67

Luscher, D.J., Bronkhorst, C.A., Alleman, C.N., and Addessio, F.L.: J. Mech. Phys. Sol., 2013. 61(9): p. 1877–94.

Lloyd, J.T., Clayton, J.D., Austin, R.A., and McDowell, D.L.: J. Mech. Phys. Sol., 2014. 69: p. 14-32.

Potirniche, G.P., Horstemeyer, M.F. and Ling, X.W.: Mech. Mater., 2007. 39: p. 941–52.

Vignjevic, R., Djordjevic, N., Campbell, J., and Panov, V.: Int. J. Impact Eng., 2012. 49: p. 61-76.

Clayton, J.D.: J. Mech. Phys. Sol., 2005. 53(2): p. 261-301.

Vogler, T. and Clayton, J.: J. Mech. Phys. Sol., 2008. 56(2): p. 297-335.

Jawad, F.F. and Zikry, M.A.: Int. J. Damage Mech., 2009. 18(4): p. 341–69.

Peralta, P., Llanes, L., Bassani, J., and Laird, C.: Phil. Mag. A, 1994. 70(1): p. 219–32.

Escobedo, J.P., Cerreta, E.K., Dennis-Koller, D., Trujillo, C.P., and Bronkhorst, C.A.: Phil. Mag., 2013. 93(7): p. 833–46.

Kocks, U.F.: Metall. Trans., 1970. 1: p. 1121–43.

Luo, S.-N., Peralta, P., Ma, C., Paisley, D.L., Greenfield, S.R., and Loomis, E.N.: Appl. Surf. Sci., 2007. 253: p. 9457–66.

T. Antoun, L. Seaman, D.R. Curran, G.I. Kanel, S.V. Razorenov, and A.V. Utkin: in High-Pressure Shock Compression of Condensed Matter, L. Davison and Y. Horie, eds., Springer-Verlag, New York, 2003.

Jones, O.E. and Motes, J.D.: J. Appl. Phys., 1969. 40(12): p. 4920–28.

Lee, E.H.: J. Appl. Mech., 1969. 36(1): p. 1–6.

Rice, J.R.:.J. Mech. Phys. Solids, 1971. 19: p. 433–55.

Bammann, D.J. and Aifantis, E.C.: Nucl. Eng. Des., 1989. 116: p. 355–62.

Asaro, R.J.: Adv. Appl. Mech., 1983. 23: 1–115.

Staroselsky, A. and Cassenti, B.N.: Mech. Mater., 2010. 42(10): p. 945–59.

Belytschko, T., Liu, W.K., and Moran, B., Nonlinear Finite Elements for Continua and Structures. 2000, Chichester, England: Wiley.

ABAQUS Software, Abaqus Theory Manual, Dassault Systemes/Simulia, 2010.

Chu, C.C. and Needleman, A.: J. Eng. Mater. Technol., 1980. 102(3): p. 249–56.

Ortiz, M. and Molinari, A.: J. Appl. Mech., 1992. 59: p. 48-53.

Tong, W. and Ravichandran, G.: J. Appl. Mech., 1995. 62: 633–39.

Chin, G.Y. and Mammel, W.L.: Trans. Metall. Soc. AIME, 1967. 239: p. 1400-05.

Peralta, P. and Laird, C.: Acta mater., 1997. 45(12): p. 5129–43.

Acknowledgments

This work was funded by LANL under the Laboratory Directed Research and Development (LDRD) program, award # 20060021DR, and by the Department of Energy, National Nuclear Security Administration (NNSA), under Grants # DE-FG52-06NA26169, DE-FG52-10NA29653, and DE-NA0002005. Eric Loomis, Pat Dickerson (LANL), Damian Swift (LLNL), David Wright, Karl Weiss, and Dallas Kingsbury (ASU) are thanked for their help during research work. Access to TRIDENT and the Electron Microscopy Lab at LANL, and the Center for High Resolution Electron Microscopy at ASU is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 6, 2014.

Appendix

Appendix

The material constants obtained from the calibration process are given below, listed in order of the equations where they are used.

Equation [5]: Reference shear strain rate \( \dot{\gamma }_{0} \) = 0.001 s−1 and rate sensitivity exponent m = 20

Equation [7]: Initial hardening modulus h 0 = 342 MPa, yield shear stress τ 0 = 26 MPa, which is in good agreement with the value of 22 MPa reported in Reference 38, stage I shear stress τ s = 90 MPa and latent hardening parameter q = 1.4.

Equation [8]: Kinematic hardening parameters k 1 = 104 MPa and k 2 = 185 MPa.

Equations [16]: parameters for the modified GTN damage model q 1 = 1.5 and q 02 = 0.5.

Equation [20]: statistical parameters for void nucleation f N = 0.04, s N = 0.1 and e N = 0.1.

Equation [21]: initial void volume fraction f 0 = 0.0001.

Rights and permissions

About this article

Cite this article

Krishnan, K., Brown, A., Wayne, L. et al. Three-Dimensional Characterization and Modeling of Microstructural Weak Links for Spall Damage in FCC Metals. Metall Mater Trans A 46, 4527–4538 (2015). https://doi.org/10.1007/s11661-014-2667-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2667-5