Abstract

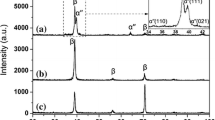

The microstructure, tensile, and creep behavior of a Ti-5Al-45Nb (at. pct) alloy was evaluated. The main objective of processing and characterizing this alloy was to obtain the constituent properties of a fully-β Ti-Al-Nb alloy to aid in modeling the tensile and creep properties of two-phase orthorhombic + body-centered-cubic (O + bcc) alloys. A second objective was to compare the tensile and creep behavior of this fully-β alloy to that for two-phase O + bcc alloys. This alloy exhibited a single-phase microstructure, containing the disordered bcc phase (β), after all the processing and heat treatments performed. This alloy was easily fabricated and workable; however, its creep resistance was significantly worse than that for fully-O and two-phase O + bcc alloys. The alloy exhibited little strain hardening along with a room-temperature yield strength (YS) of 545 MPa, an ultimate tensile stress (UTS) of 559 MPa, a Young’s modulus (E) of 86 GPa, and a tensile elongation to failure of 25 pct. Extensive surface slip was evident on the deformed material. Its room-temperature tensile properties were quite similar to those for a fully-β Ti-12Al-38Nb microstructure (YS = 553 MPa, UTS = 566 MPa, E = 84, and ε f > 27 pct). Thus, the room-temperature tensile properties and behavior of fully-β Ti-Al-Nb microstructures containing 50 at. pct Ti are not sensitive to compositional variations between 5 to 12 at. pct Al and 38 to 45 at. pct Nb.

Similar content being viewed by others

Notes

Henceforth, all alloy compositions are given in atomic percent.

References

M.F. Bartholomeusz, J.A. Wert: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 3257–64

M.F. Bartholomeusz, J.A. Wert: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 2161–71

H.T. Kestner-Weykamp, C.W. Ward, T.F. Broderick, M.J. Kaufman: Scripta Metall., 1989, vol. 23, pp. 1697–1702

L.A. Bendersky, W.J. Boettinger, A. Roytburd: Acta Metall. Mater., 1991, vol. 39, pp. 1059–69

C.G. Rhodes, J.A. Graves, P.R. Smith, M.R. James: in Structural Intermetallics, R. Darolia, J.J. Lewandowski, C.T. Liu, P.L. Martin, D.B. Miracle, M.V. Nathal, eds., TMS, Warrendale, PA, 1993, pp. 45–52

C.J. Cowen, C.J. Boehlert: Phil. Mag., 2006, vol. 86, pp. 99–124

C.J. Boehlert, B.S. Majumdar, V. Seetharaman, D.B. Miracle: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2305–23

P.R. Smith, A. Rosenberger, M.J. Shepard: Scripta Mater., 1999, vol. 41, pp. 221–28

S.R. Woodard and T.M. Pollock: in Orthorhombic Titanium Matrix Composites II, AF TR WL-TR-97-4082, P.R. Smith, ed., Wright-Patterson Air Force Base, OH, 1997, pp. 265–76

R.G. Rowe, M. Larsen: in Titanium ‘95, P.A. Blenkinsop, W.J. Evans, H.M. Flower, eds., The University Press, Cambridge, United Kingdom, 1996, pp. 364–71

C.J. Boehlert, D.B. Miracle: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 2349–67

C.J. Boehlert, J.F. Bingert: J. Mater. Process. Technol., 2001, vol. 117, pp. 401–09

R.W. Hayes: Scripta Metall., 1996, vol. 34 (6), pp. 1005–1112

P.R. Smith, M. Khobaib, J.A. Graves: Scripta Metall., 1993, vol. 29, pp. 1313–18

J.C. Chesnutt, R.A. Amato, C.M. Austin, R.L. Fleischer, M.F.X. Gigliotti, D.A. Hardwick, S.C. Huang, D.G. Konitzer, M.M. Lee, P.L. Martin, C.G. Rhodes, R.G. Rowe, G.K. Scarr, D.S. Shih, and P.A. Zomcik: in Very High Temperature Titanium-Base Materials Research, WL-TR-91-4070, GE Aircraft Engines, Cincinnati, OH, 1993

C.J. Boehlert: Mater. Sci. Eng., 1999, vol. A267, pp. 82–98

C.M. Austin, J.R. Dobbs, H.L. Fraser, D.G. Konitzer, D.J. Miller, M.J. Parks, J.C. Schaeffer, and J.W. Sears: in Rapidly Solidified Oxidation Resistant Niobium Base Alloys, WL-TR-93-4059, GE Aircraft Engines, Cincinnati, OH, 1992

R.G. Rowe, D.G. Konitzer, A.P. Woodfield, and J.C. Chesnutt: in High Temperature Ordered Intermetallic Alloys-IV, L.A. Johnson, D.P. Pope, and J.O. Stiegler, eds., Materials Research Society, Pittsburgh, PA, 1991, vol. 231, pp. 703–08

P.R. Smith, J.A. Graves, C.G. Rhodes: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1267–83

P.R. Smith, W.J. Porter, W.J. Kralik, and J.A. Graves: Metal Matrix Composites, Proc. 10th Int. Conf. on Composite Materials, A. Poursartip and K.N. Street, eds., Woodhead Publishing Ltd., Cambridge, UK, 1995, vol. 2, pp. 731–38

B.S. Majumdar, C.J. Boehlert, A.K. Rai, and D.B. Miracle: in High Temperature Ordered Intermetallic Alloys-VI, J. Horton, I. Baker, S. Hanada, R.D. Noebe, and D.S. Schwartz, eds., Materials Research Society, Pittsburgh, PA, 1995, vol. 364, pp. 1259–65

P.R. Smith, A. Rosenberger, M.J. Shepard, R. Wheeler: J. Mater. Sci., 2000, vol. 35, pp. 3169–79

C.F. Yolton, J.P. Beckman: Mater. Sci. Eng., 1995, vols. A192–A193, pp. 597–603

J.W. Zhang, C.S. Lee, D.X. Zou, S.Q. Li, J.K.L. Lai: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 559–64

C.J. Cowen, C.J. Boehlert: Intermetallics, 2006, vol. 14, pp. 412–22

C.J. Cowen and C.J. Boehlert: Adv. Mater. Res., 2007, Part 1, vols. 15–17, pp. 976–81

C.J. Boehlert, B.S. Majumdar, V. Seetharaman, D.B. Miracle, R. Wheeler: in Structural Intermetallics, R. Darolia, J.J. Lewandowski, C.T. Liu, P.L. Martin, D.B. Miracle, M.V. Nathal, eds., TMS, Warrendale, PA, 1997, pp. 795–804

C.G. Rhodes, P.R. Smith, W.H. Hanusiak, M.J. Shephard: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2931–41

C.J. Boehlert: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1977–88

A.K. Gogia, T.K. Nandy, K. Muraleedharan, D. Banerjee: Mater. Sci. Eng., A, 1992, vol. 159, pp. 73–86

F.C. Dary, T.M. Pollock: Mater. Sci. Eng., 1996, vol. A208 (2), p. 188–202

F. Popille, J. Douin: Phil. Mag., 1996, vol. 73, pp. 1401–18

D. Banerjee, A.K. Gogia, T.K. Nandy, K. Muraleedharan, R.S. Mishra: in Structural Intermetallics, R. Darolia, J.J. Lewandowski, C.T. Liu, P.L. Martin, D.B. Miracle, M.V. Nathal, eds., TMS, Warrendale, PA, 1993, pp. 19–33

T.K. Nandy, R.S. Mishra, D. Banerjee: Scripta Metall. Mater., 1993, vol. 28, pp. 569–74

T.K. Nandy, R.S. Mishra, A.K. Gogia, D. Banerjee: Scripta Metall. Mater., 1995, vol. 32, pp. 851–56

T.K. Nandy, D. Banerjee: Intermetallics, 2000, vol. 8, pp. 915–28

J.E. Hilliard: Met. Progr., 1964, vol. 78, pp. 99–100

Standard Test Methods for Determining Average Grain Size, ASTM Designation E112-96e3, ASTM, West Conshohocken, PA, 1996

R.W. Evans and B. Wilshire: in Creep of Metals and Alloys, The Institute of Metals, New York, NY, 1985

R.W. Hertzberg: in Deformation and Fracture Mechanics of Engineering Materials, 4th ed., John Wiley and Sons, New York, NY, 1996

D.L. Moffat and U.R. Kattner: Metall. Trans. A, 1988, vol. 19A, pp. 2389–97

C.J. Cowen and C.J. Boehlert: in Advanced Intermetallic-Based Alloys, C.L. Fu, H. Clemens, J. Wiezorek, M. Takeyama, and D. Morris, eds., Materials Research Society, Pittsburgh, PA, 2007, vol. 980, paper no. 0980-II05-05

R.S. Mishra, D. Banerjee: Mater. Sci. Eng., 1990, vol. A130, pp. 151–64

A. Kelly, K.N. Street: Proc. R. Soc. London A, 1972, vol. 328, pp. 283–93

Acknowledgment

This work was supported by the National Science Foundation through Grant No. DMR-0533954.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 18, 2007.

Rights and permissions

About this article

Cite this article

Cowen, C., Boehlert, C. The Microstructure, Creep, and Tensile Behavior for Ti-5Al-45Nb (Atomic Percent) Fully-β Alloy. Metall Mater Trans A 38, 2747–2753 (2007). https://doi.org/10.1007/s11661-007-9322-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9322-3