Abstract

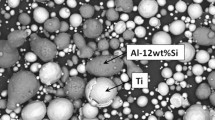

In order to improve the oxidation resistance of TiAl alloy, silicide coatings were prepared by pack cementation method at 1273, 1323, and 1373K for 1-3 hours. Scanning electron microscopy (SEM), energy dispersive spectrometry (EDS) and X-ray diffraction (XRD) were employed to investigate the microstructures and phase constitutions of the coatings. The experimental results show that all silicon deposition coatings have multi-layer structure. The microstructure and composition of silicide coatings strongly depend on siliconizing temperatures. In order to investigate the rate controlling step of pack siliconizing on TiAl alloy, coating growth kinetics was analyzed by measuring the mass gains per unit area of silicided samples as a function of time and temperature. The results showed that the rate controlling step was gas-phase diffusion step and the growth rate constant (k) ranged from 1.53 mg2/(cm4·h2) to 2.3 mg2/(cm4·h2). Activation energy (Q) for the process was calculated as 109 kJ/mol, determined by Arrhenius' equation: k = k 0 exp[–Q/(RT)].

Similar content being viewed by others

References

Pflumm R, Friedle S, Schütze M. Oxidation Protection of γ-TiAl-based Alloys-A Review[J]. Intermetallics, 2015: 1–14

Xiang ZD, Rose SR, Burnell-Gray JS, et al. Co-deposition of Aluminide and Silicide Coatings on γ-TiAl by Pack Cementation Process[J]. Journal of Materials Science, 2003, 38(1): 19–28

Chen YY, Xiao SL, Wang ZT, et al. The Effect of Yttrium Addition on the Oxidation Resistance of Ti2AlNb Based Alloy[J]. Journal of Wuhan University of Technology, 2009(S1): 5–8

Goral M, Swadzba L, Moskal G, et al. Si-modified Aluminide Coatings Deposited on Ti46Al7Nb Alloy by Slurry Method[J]. Intermetallics, 2009, 17(11): 965–967

Li XY, Taniguchi S, Matsunaga Y, et al. Influence of Siliconizing on the Oxidation Behavior of a γ-TiAl-based Alloy[J]. Intermetallics, 2003, 11: 143–150

Koo CH, Yu TH. Pack Cementation Coatings on Ti3Al-Nb Alloys to Modify the High-temperature Oxidation Properties[J]. Surface & Coatings Technology, 2000, 126: 171–180

Bai CY, Luo YJ, Koo CH. Improvement of High Temperature Oxidation and Corrosion Resistance of Superalloy IN-738LC by Pack Cementation[J]. Surface & Coatings Technology, 2004, 183(1): 74–88

Cockeram BV, Rapp RA. The Kinetics of Multilayered Titanium-silicide Coatings Grown by the Pack Cementation Method[J]. Metallurgical & Materials Transactions A, 1995, 26(4): 777–791

Bianco R, Harper MA, Rapp RA. Codepositing Elements by Halide-Activated Pack Cementation[J]. Jom the Journal of the Minerals Metals & Materials Society, 1991, 43(11): 68–73

Cockeram BV and Rapp RA. The Kinetics of Multilayered Titaniumsilicide Coatings Grown by the Pack Cementation Method[J]. Metallurgical & Materials Transactions A, 1995, 26(4): 777–791

Gupta BK, Sarkhel AK, Seigle LL. On the kinetics of pack aluminization[J]. Thin Solid Films, 1976: 313–320

John J. A Kinetic Model for Iron Aluminide Coating by Low Pressure Chemical Vapor Deposition: Part II. Model Formulation[J]. Thin Solid Films, 2004, 466: 331–338

Levine SR and Caves RM. Thermodynamics and Kinetics of Pack Aluminide Coating Formation on IN0[J]. Journal of the Electrochemical Society, 1973, 121(8): 1051–1064

Zarchi H, Msoltanieh Mraboutalebi, et al. Kinetic study on NaFactivated Pack-aluminizing of Pure Titanium at 950–1100 °C[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1959–1968

Guo XP, Zhao LX, Guan P, et al. Oxidation Behavior and Pack Siliconized Oxidation-resistant Coatings of an Nb-Based Ultrahigh Temperature Alloy[J]. Materials Science Forum, 2007, 561–565

Hickl AJ and Heckel RW. Kinetics of Phase Layer Growth during Aluminide Loating of Nicke[J]. Metall. Trans. A, 1975, 6A: 431–452

Cockeram BV, Rapp RA. The Kinetics of Multilayered Titaniumsilicide Coatings Grown by the Pack Cementation Method[J]. Metallurgical & Materials Transactions A, 1995, 26(4):777–791

Lin NM, Xie FQ, Zou JJ, et al. Application of Artificial Neural Network in Predicting the Thickness of Chromizing Coatings on P110 Steel[J]. Journal of Wuhan University of Technology, 2013, 28(1): 196–201

Li YQ, Xie FQ, Wu XQ, et al. Effects of Y2O3 on the Microstructures and Wear Resistance of Si-Al-Y Co-deposition Coatings Prepared on Ti-Al Alloy by Pack Cementation Technique[J]. Applied Surface Science, 2013, 287(2): 30–36

Tian XD, Guo XP. Structure and Oxidation Behavior of Si-Y Codeposition Coatings on an Nb Silicide Based Ultrahigh Temperature Alloy Prepared by Pack Cementation Technique[J]. Surface & Coatings Technology, 2009, 204(3): 313–318

John J. A Kinetic Model for Iron Aluminide Coating by Low Pressure Chemical Vapor Deposition: Part II. Model Formulation[J]. Thin Solid Films, 2004, 466: 331–338

Popela T, Vojtech D, Vogt JB, et al. Structural, Mechanical and Oxidation Characteristics of Siliconized Ti-Al-X (X = Nb, Ta) Alloys[J]. Applied Surface Science, 2014, 307(1): 579–588

Ugur S, Azkan O, Senol Y, et al. Kinetics of Iron Silicide Deposited on AISI D2 Steel by Pack Method[J]. Metal, 2013, 2013, 5: 15–21

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Natural Science Program for Basic Research in Key Areas of Shaanxi Province (2014JZ012)

Rights and permissions

About this article

Cite this article

Huang, L., Wu, X., Xie, F. et al. Microstructure and growth kinetics of silicide coatings for TiAl alloy. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 245–249 (2017). https://doi.org/10.1007/s11595-017-1587-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1587-9