Abstract

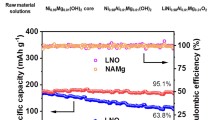

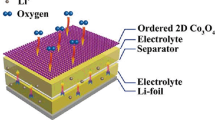

The porous spherical LiNi1/3Co1/3Mn1/3O2 has been synthesized using CaCO3-template and a conventional solid-state reaction. The physical and electrochemical properties of the materials are examined by many characterizations including XRD, SEM, EDS, BET, CV, EIS, and galvanostatic charge–discharge cycling. The results indicate that the as-synthesized materials prepared by this new method own a well-ordered layered α-NaFeO2 structure (space group: R-3m (166)). And massively porous channels could be observed in the spherical LiNi1/3Co1/3Mn1/3O2. Compared with the firm-surface spherical LiNi1/3Co1/3Mn1/3O2, the porous spherical material exhibits larger specific surface area and superior electrochemical performances. It delivers a higher initial capacity of 164.0 mAh g−1 at 0.1 C (1 C = 180 mA g−1) between 2.7 and 4.3 V, and 93.5 mAh g−1 is still respectively reached at 20 C. After 100 charge–discharge cycles at 1 C in the range of 2.7–4.3 V, the capacity retention is 95.1 %, indicating excellent cycling stability.

Similar content being viewed by others

References

Hyung Choi I, Min Choi J, Ju Hwang Y, Aravindan V, Sung Lee Y, Suk Nahm K (2014) Influence of dilution effect on the electrochemical performance of integrated 0.5Li(Mn1.5Ni0.5)O4 · 0.5(Li2MnO3–Li(Mn0.5Ni0.5)O2) cathodes. Ceram Int 408:13033–13039

Yu X, Lyu Y, Gu L, Wu H, Bak SM, Zhou Y, Amine K, Ehrlich SN, Li H, Nam KW, Yang XQ (2014) Understanding the rate capability of high-energy-density Li-rich layered li1.2Ni0.15Co0.1Mn0.55O2 cathode materials. Adv Energy Mater 45:1–11

Sun YK, Kang HB, Myung ST, Prakash J (2010) Effect of manganese content on the electrochemical and thermal stabilities of Li[Ni0.58Co0.28−x Mn0.14+x ]O2 cathode materials for lithium-ion batteries. J Electrochem Soc 15712:A1335–A1340

Jiang KC, Xin S, Lee JS, Kim J, Xiao XL, Guo YG (2012) Improved kinetics of LiNi1/3Mn1/3Co1/3O2 cathode material through reduced graphene oxide networks. Phys Chem Chem Phys 148:2934–2939

Liang L, Du K, Peng Z, Cao Y, Duan J, Jiang J, Hu G (2014) Co–precipitation synthesis of Ni0.6Co0.2Mn0.2(OH)2 precursor and characterization of LiNi0.6Co0.2Mn0.2O2 cathode material for secondary lithium batteries. Electrochim Acta 130:82–89

Ou QZ, Tang Y, Zhong YJ, Guo XD, Zhong BH, Heng L, Chen MZ (2014) Submicrometer porous Li3V2(PO4)3/C composites with high rate electrochemical performance prepared by sol–gel combustion method. Electrochim Acta 137:489–496

Yang S, Chen J, Liu Y, Yi B (2014) Preparing LiNi0.5Mn1.5O4 nanoplates with superior properties in lithium-ion batteries using bimetal-organic coordination-polymers as precursors. J Mater Chem A 224:9322–9330

Noh H-J, Youn S, Yoon CS, Sun YK (2013) Comparison of the structural and electrochemical properties of layered Li[Ni x Co y Mn z ]O2 (x = 1/3, 0.5, 0.6, 0.7, 0.8 and 0.85) cathode material for lithium-ion batteries. J Power Sources 233:121–130

Xu Z, Xiao L, Wang F, Wu K, Zhao L, Li MR, Zhang HL, Wu Q, Wang J (2014) Effects of precursor, synthesis time and synthesis temperature on the physical and electrochemical properties of Li(Ni1−x−y Co x Mn y )O2 cathode materials. J Power Sources 248:180–189

Yang S, Wang X, Chen Q, Yang X, Li J, Wei Q (2011) Effects of complexants on [Ni1/3Co1/3Mn1/3]CO3 morphology and electrochemical performance of LiNi1/3Co1/3Mn1/3O2. J Solid State Electrochem 162:481–490

Li J, Xiong S, Liu Y, Ju Z, Qian Y (2013) Uniform LiNi1/3Co1/3Mn1/3O2 hollow microspheres: designed synthesis, topotactical structural transformation and their enhanced electrochemical performance. Nano Energy 26:1249–1260

Yang Z, Lu J, Bian D, Zhang W, Yang X, Xia J, Chen G, Gu H, Ma G (2014) Stepwise co-precipitation to synthesize LiNi1/3Co1/3Mn1/3O2 one-dimensional hierarchical structure for lithium ion batteries. J Power Sources 272:144–151

He P, Wang H, Qi L, Osaka T (2006) Electrochemical characteristics of layered LiNi1/3Co1/3Mn1/3O2 and with different synthesis conditions. J Power Sources 1601:627–632

Hua W, Zhang J, Zheng Z, Liu W, Peng X, Guo XD, Zhong B, Wang YJ, Wang X (2014) Na-doped Ni-rich LiNi0.5Co0.2Mn0.3O2 cathode material with both high rate capability and high tap density for lithium ion batteries. Dalton Trans 4339:14824–14832

Weng Y, Xu S, Huang G, Jiang C (2013) Synthesis and performance of Li[(Ni1/3Co1/3Mn1/3)(1−x)Mg x O2 prepared from spent lithium ion batteries. J Hazard Mater 246–247:163–172

Li Q, Li G, Fu C, Luo D, Fan J, Li L (2014) K+-doped Li1.2Mn0.54Co0.13Ni0.13O2: a novel cathode material with an enhanced cycling stability for lithium-ion batteries. ACS Appl Mater Interfaces 613:10330–10341

Chen Y, Zhang Y, Chen B, Wang Z, Lu C (2014) An approach to application for LiNi0.6Co0.2Mn0.2O2 cathode material at high cutoff voltage by TiO2 coating. J Power Sources 256:20–27

Yao Y, Liu H, Li G, Peng H, Chen K (2013) Synthesis and electrochemical performance of phosphate-coated porous LiNi1/3Co1/3Mn1/3O2 cathode material for lithium ion batteries. Electrochim Acta 113:340–345

Shi H, Wang X, Hou P, Zhou E, Guo J, Zhang J, Wang D, Guo F, Song D, Shi X, Zhang L (2014) Core–shell structured Li[(Ni0.8Co0.1Mn0.1)0.7(Ni0.45Co0.1Mn0.45)0.3]O2 cathode material for high-energy lithium ion batteries. J Alloy Compd 587:710–716

Liang LW, Du K, Peng ZD, Cao YB, Hu GR (2014) Synthesis and electrochemical performance of LiNi0.6Co0.2Mn0.2O2 as a concentration-gradient cathode material for lithium batteries. Chin Chem Lett 256:883–886

Huang Z-D, Liu XM, Oh SW, Zhang B, Ma PC, Kim JK (2011) Microscopically porous, interconnected single crystal LiNi1/3Co1/3Mn1/3O2 cathode material for lithium ion batteries. J Mater Chem 2129:10777–10784

Kim KJ, Jo YN, Lee WJ, Subburaj T, Prasanna K, Lee CW (2014) Effects of inorganic salts on the morphological, structural, and electrochemical properties of prepared nickel-rich Li[Ni0.6Co0.2Mn0.2]O2. J Power Sources 268:349–355

Hu M, Tian Y, Wei J, Wang D, Zhou Z (2014) Porous hollow LiCoMnO4 microspheres as cathode materials for 5 V lithium ion batteries. J Power Sources 247:794–798

Zhang L, Borong W, Ning L, Feng W (2014) Hierarchically porous micro-rod lithium-rich cathode material Li1.2Ni0.13Mn0.54Co0.13O2 for high performance lithium-ion batteries. Electrochim Acta 118:67–74

Yao Y, Liu H, Li G, Peng H, Chen K (2014) Multi-shelled porous LiNi0.5Mn1.5O4 microspheres as a 5 V cathode material for lithium-ion batteries. Mater Chem Phys 1432:867–872

Penki TR, Shanmughasundaram D, Munichandraiah N (2014) Porous lithium rich Li1.2Mn0.54Ni0.22Fe0.04O2 prepared by microemulsion route as a high capacity and high rate capability positive electrode material. Electrochim Acta 143:152–160

Xiong W, Jiang Y, Yang Z, Li D, Huang Y (2014) High-performance hierarchical LiNi1/3Mn1/3Co1/3O2 microspheres synthesized via a facile template-sacrificial route. J Alloy Compd 589:615–621

Li J, Cao C, Xu X, Zhu Y, Yao R (2013) LiNi1/3Co1/3Mn1/3O2 hollow nano-micro hierarchical microspheres with enhanced performances as cathodes for lithium-ion batteries. J Mater Chem A 138:11848–11852

Massoni N, Le Gallet S, Hoffmann S, Launeau P, Grin Y, Bernard F (2015) Sintering of synthetic barytocalcite BaCa(CO3)2, kutnahorite CaMn(CO3)2 and rhodochrosite MnCO3 for carbon-14 sequestration. J Eur Ceram Soc 351:297–308

He YS, Ma ZF, Liao XZ, Jiang Y (2007) Synthesis and characterization of submicron-sized LiNi1/3Co1/3Mn1/3O2 by a simple self-propagating solid-state metathesis method. J Power Sources 1632:1053–1058

Huang X, Wang M, Che R (2014) Modulating the Li+/Ni2+ replacement and electrochemical performance optimizing of layered lithium-rich Li1.2Ni0.2Mn0.6O2 by minor Co dopant. J Mater Chem A 225:9656–9665

Deng C, Zhang S, Wu B, Yang SY, Li HQ (2009) Synthesis and characteristics of nanostructured Li(Co1/3Ni1/3Mn1/3)O2 cathode material prepared at 0 °C. J Solid State Electrochem 145:871–875

Oljaca M, Blizanac B, Du Pasquier A, Sun Y, Bontchev R, Suszko A, Wall R, Koehlert K (2014) Novel Li(Ni1/3Co1/3Mn1/3)O2 cathode morphologies for high power Li-ion batteries. J Power Sources 248:729–738

Hua WB, Guo XD, Zheng Z, Wang YJ, Zhong BH, Fang B, Wang JZ, Chou SL, Liu H (2015) Uncovering a facile large-scale synthesis of LiNi1/3Co1/3Mn1/3O2 nanoflowers for high power lithium-ion batteries. J Power Sources 275:200–206

Huang ZD, Liu XM, Zhang B, Oh SW, Ma PC, Kim JK (2011) LiNi1/3Co1/3Mn1/3O2 with a novel one-dimensional porous structure: a high-power cathode material for rechargeable Li-ion batteries. Scr Mater 642:122–125

Wu SL, Zhang W, Song X, Shukla AK, Liu G, Battaglia V, Srinivasan V (2012) High rate capability of Li(Ni1∕3Mn1∕3Co1∕3)O2 electrode for li-ion batteries. J Electrochem Soc 1594:A438–A444

Gao P, Yang G, Liu H, Wang L, Zhou H (2012) Lithium diffusion behavior and improved high rate capacity of LiNi1/3Co1/3Mn1/3O2 as cathode material for lithium batteries. Solid State Ionics 207:50–56

Yin K, Fang W, Zhong B, Guo X, Tang Y, Nie X (2012) The effects of precipitant agent on structure and performance of LiNi1/3Co1/3Mn1/3O2 cathode material via a carbonate co-precipitation method. Electrochim Acta 85:99–103

Ohzuku T, Ueda A, Nagayama M (1993) Electrochemistry and structural chemistry of LiNiO2 (R3m) for 4 volt secondary lithium cells. J Electrochem Soc 1407:1862–1870

Liu X, Li H, Li D, Ishida M, Zhou H (2013) PEDOT modified LiNi1/3Co1/3Mn1/3O2 with enhanced electrochemical performance for lithium ion batteries. J Power Sources 2430:374–380

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 575 kb)

Rights and permissions

About this article

Cite this article

Zhang, J., Wu, Z., Hua, W. et al. High-performance porous spherical cathode materials based on CaCO3-template synthesis of LiNi1/3Co1/3Mn1/3O2 for lithium-ion batteries. Ionics 21, 3151–3158 (2015). https://doi.org/10.1007/s11581-015-1501-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-015-1501-4