Abstract

Purpose

The aim of this work was to introduce a computer-aided design (CAD) tool that enables the design of large skull defect (>100 \(\mathrm{cm}^2\)) implants. Functional and aesthetically correct custom implants are extremely important for patients with large cranial defects. For these cases, preoperative fabrication of implants is recommended to avoid problems of donor site morbidity, sufficiency of donor material and quality. Finally, crafting the correct shape is a non-trivial task increasingly complicated by defect size.

Methods

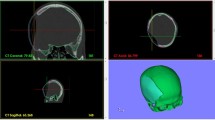

We present a CAD tool to design such implants for the neurocranium. A combination of geometric morphometrics and radial basis functions, namely thin-plate splines, allows semiautomatic implant generation. The method uses symmetry and the best fitting shape to estimate missing data directly within the radiologic volume data. In addition, this approach delivers correct implant fitting via a boundary fitting approach.

Results

This method generates a smooth implant surface, free of sharp edges that follows the main contours of the boundary, enabling accurate implant placement in the defect site intraoperatively. The present approach is evaluated and compared to existing methods. A mean error of 89.29 % (72.64–100 %) missing landmarks with an error less or equal to 1 mm was obtained.

Conclusion

In conclusion, the results show that our CAD tool can generate patient-specific implants with high accuracy.

Similar content being viewed by others

References

Parthasarathy J (2014) 3D modeling, custom implants and its future perspectives in craniofacial surgery. Ann Maxillofac Surg 4(1):9–18

Liao YL, Lu CF, Wu CT, Lee JD, Lee ST, Sun YN, Wu YT (2013) Using three-dimensional multigrid-based snake and multiresolution image registration for reconstruction of cranial defect. Med Biol Eng Comput 51(19):89–101

Rotaru H, Stan H, Florian IS, Schumacher R, Park YT, Kim SG, Chezan H, Balc N, Baciut M (2012) Cranioplasty with custom-made implants: analyzing the cases of 10 patients. J Oral Maxillofac Surg 70(2):169–176

Liao YL, Lu CF, Sun YN, Wu CT, Lee JD, Lee ST, Wu YT (2011) Three-dimensional reconstruction of cranial defect using active contour model and image registration. Med Biol Eng Comput 49(2):203–211

Lüthi M, Albrecht T, Vetter T (2009) Building shape models from lousy data. MICCAI LNCS 5762:1–8

Wu T, Engelhardt M, Fieten L, Popovic A, Radermacher K (2006) Anatomically constrained deformation for design of cranial implant: Methodology and validation. MICCAI LNCS 4190:9–16

Hierl T, Wollny G, Schulze FP, Scholz E, Schmidt JG, Berti G, Hendricks J, Hemprich A (2006) CAD-CAM implants in esthetic and reconstructive craniofacial surgery. J Comput Inf Technol 1:65–70

Dean D, Min KJ, Bond A (2003) Computer aided design of pre-fabricated cranial plates. J Craniofac Surg 14:819–832

Min KJ, Dean D (2003) Highly accurate CAD tools for cranial implants. MICCAI LNCS 2878:99–107

Min KJ, (2003) Computer aided design of cranial implants using deformable templates, PhD thesis, Case Western Reserve University, Cleveland Ohio

Eufinger H, Saylor B (2001) Computer-assisted prefabrication of individual craniofacial implants. AORN J 74:648–654

Hsu J, Tseng C (2001) Application of three-dimensional orthogonal neural network to craniomaxillary reconstruction. Comput Med Imaging Graph 25:477–482

Hsu J, Tseng C (2000) Application of three-dimensional orthogonal neural network to craniomaxillary reconstruction. J Med Eng Technol 24:262–266

Carr JC, Fright WR, Beatson RK (1997) Surface interpolation with radial basis functions for medical imaging. IEEE Trans Med Imaging 16:96–107

Wehmöller M, Eufinger H, Kruse D, Massberg W (1995) CAD by processing of computed tomography data and CAM of individually designed prostheses. Int J Oral Maxillofac Surg 24:90–97

Bookstein FL (1991) Morphometric tools for landmark data: geometry and biology. cambridge University Press, Cambridge

Slice DE (2005) Modern morphometrics in physical anthropology. Kluwer Academic-Prenum Publishers, New York

Stegmann MB, Gomez DD (2002) A brief introduction to statistical shape analysis, technical report, informatics and mathematical modelling. Technical University of Denmark, DTU, Copenhagen

Carr JC, Beatson RK, Cherrie JB, Mitchell TJ, Fright WR, McCallum BC, Evans TR, (2001) Reconstruction and representation of 3D objects with radial basis functions. Computer Graphics (SIGGRAPH 01 Conf. Proc.), :67–76

Heuzé Y, Marreiros FMM, Verius M, Eder R, Huttary R, Recheis W (2008) The use of procrustes average shape in the design of custom implant surface for large skull defects. Int J Comput Assist Radiol Surg 3(1):283–284

Bookstein FL (1989) Principal warps: thin-plate splines and the decomposition of deformations. IEEE Trans Pattern Anal Mach Intell 6:567–585

Bookstein FL (1997) Landmark methods for forms without landmarks: morphometrics of group differences in outline shape. Med Image Anal 1:225–243

Gunz P, Mitteroecker P, Bookstein FL (2005) Semilandmarks in three dimensions. In: Modern morphometrics in physical anthropology. Kluwer Academic/Plenum Publishers, New York, pp 73–98

Rohlf FJ, Slice D (1990) Extensions of the procrustes method for the optimal superimposition of landmarks. Syst Zool 39:40–59

Schroeder W, Martin K, Lorensen B (1997) The visualization toolkit: an object-oriented approach to 3D graphics. Prentice Hall, New Jersey

Rosenfeld A, Pfaltz JL (1966) Sequential operations in digital picture processing. J ACM 13(4):471–494

Shapiro LG, Stockman GC (2002) Computer vision. Prentice Hall, New Jersey

Moore-Jansen PH, Ousely SD, Jantz R (1994) Data collection procedures for forensic skeletal material. University of tennessee Forensic Anthropology Series, Tennessee

Aeillo L, Dean C (1990) An introduction to human evolutionary anatomy. Academic Press, London

Drebin RA, Carpenter L, Hanrahan P (1988) Volume rendering. Comput Graphics 22(4):65–74

Levoy M (1988) Display of surfaces from volume data. IEEE Comput Graphics Appl 8(3):29–37

Levoy M (1990) Efficient ray tracing of volume data. ACM Trans Graph 9:245–261

Sobel I, Feldman G (1968) A \(3 \times 3\) isotropic gradient operator for image processing. https://www.researchgate.net/publication/239398674_An_Isotropic_3_3_Image_Gradient_Operator

Deutsch ES (1972) Thinning algorithms on rectangular, hexagonal, and triangular arrays. Commun ACM 15:827–837

Nyquist H (1928) Certain topics in telegraph transmission theory. Trans Am Inst Elect Eng 47:617–644

Shannon CE (1949) Communication in the presence of noise. Proc of the IRE 37(1):10–21

Jin X, Sun H, Peng Q (2003) Subdivision interpolating implicit surfaces. Comput Graphics 27:763–772

Poukens J, Laeven P, Beerens M, Nijenhuis G, Sloten JV, Stoelinga P, Kessler P (2008) A classification of cranial implants based on the degree of difficulty in computer design and manufacture. Int J Med Robot Comput Assist Surg 4:46–50

Turk G, O’Brien JF (2002) Modelling with implicit surfaces that interpolate. ACM Trans Graph 21:855–873

Acknowledgments

The authors would like to thank Brenda Frazier for editorial suggestions. We would like also to thank Philipp Gunz and Demetrios Halazonetis for their explanations of GM methods used in this work. This work was supported by the EU FP6 Marie Curie Actions EVAN, contract number: MRTN-CT-2005-019564.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

For this type of study, formal consent is not required, since all the patient data were anonymized.

Rights and permissions

About this article

Cite this article

Marreiros, F.M.M., Heuzé, Y., Verius, M. et al. Custom implant design for large cranial defects. Int J CARS 11, 2217–2230 (2016). https://doi.org/10.1007/s11548-016-1454-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11548-016-1454-8