Abstract

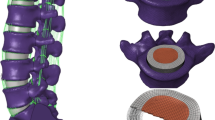

Subsidence, when implant penetration induces failure of the vertebral body, occurs commonly after spinal reconstruction. Anterior lumbar interbody fusion (ALIF) cages may subside into the vertebral body and lead to kyphotic deformity. No previous studies have utilized an artificial neural network (ANN) for the design of a spinal interbody fusion cage. In this study, the neural network was applied after initiation from a Taguchi L 18 orthogonal design array. Three-dimensional finite element analysis (FEA) was performed to address the resistance to subsidence based on the design changes of the material and cage contact region, including design of the ridges and size of the graft area. The calculated subsidence is derived from the ANN objective function which is defined as the resulting maximum von Mises stress (VMS) on the surface of a simulated bone body after axial compressive loading. The ANN was found to have minimized the bone surface VMS, thereby optimizing the ALIF cage given the design space. Therefore, the Taguchi-FEA-ANN approach can serve as an effective procedure for designing a spinal fusion cage and improving the biomechanical properties.

Similar content being viewed by others

References

Bagby G W. Arthrodesis by the distraction-compression method using a stainless steel implant. Orthopedics, 1988, 11(6): 931–934

Cain C M, Schleicher P, Gerlach R, Pflugmacher R, Scholz M, Kandziora F. A new stand-alone anterior lumbar interbody fusion device: biomechanical comparison with established fixation techniques. Spine, 2005, 30(23): 2631–2636

Dietl R H J, Krammer M, Kettler A, Wilke H J, Claes L, Lumenta C B. Pullout test with three lumbar interbody fusion cages. Spine, 2002, 27(10): 1029–1036

McAfee P C. Interbody fusion cages in reconstructive operations on the spine. Journal of Bone and Joint Surgery. American Volume, 1999, 81(6): 859–880

Engels T A, Söntjens S H, Smit T H, Govaert L E. Time-dependent failure of amorphous polylactides in static loading conditions. Journal of Materials Science. Materials in Medicine, 2010, 21(1): 89–97

Kandziora F, Pflugmacher R, Scholz M, Eindorf T, Schnake K J, Haas N P. Bioabsorbable interbody cages in a sheep cervical spine fusion model. Spine, 2004, 29(17): 1845–1856

Smit T H, Engels T A, Wuisman P I, Govaert L E. Time-dependent mechanical strength of 70/30 Poly(L, DL-lactide): shedding light on the premature failure of degradable spinal cages. Spine, 2008, 33(1): 14–18

Hackenberg L, Halm H, Bullmann V, Vieth V, Schneider M, Liljenqvist U. Transforaminal lumbar interbody fusion: A safe technique with satisfactory three to five year results. European Spine Journal, 2005, 14(6): 551–558

Adam C, Pearcy M, McCombe P. Stress analysis of interbody fusion-Finite element modelling of intervertebral implant and vertebral body. Clinical Biomechanics (Bristol, Avon), 2003, 18(4): 265–272

Jost B, Cripton P A, Lund T, Oxland T R, Lippuner K, Jaeger P, Nolte L P. Compressive strength of interbody cages in the lumbar spine: the effect of cage shape, posterior instrumentation and bone density. European Spine Journal, 1998, 7(2): 132–141

Kim Y. Prediction of mechanical behaviors at interfaces between bone and two interbody cages of lumbar spine segments. Spine, 2001, 26(13): 1437–1442

Lim T H, Kwon H, Jeon C H, Kim J G, Sokolowski M, Natarajan R, An H S, Andersson G B. Effect of endplate conditions and bone mineral density on the compressive strength of the graft-endplate interface in anterior cervical spine fusion. Spine, 2001, 26(8): 951–956

Steffen T, Tsantrizos A, Aebi M. Effect of implant design and endplate preparation on the compressive strength of interbody fusion constructs. Spine, 2000, 25(9): 1077–1084

Steffen T, Tsantrizos A, Fruth I, Aebi M. Cages: Designs and concepts. European Spine Journal, 2000, 9(Suppl 1): S89–S94

Pearcy M J, Evans J H, O’Brien J P. The load bearing capacity of vertebral cancellous bone in interbody fusion of the lumbar spine. Engineering in Medicine, 1983, 12(4): 183–184

Zander T, Rohlmann A, Klöckner C, Bergmann G. Effect of bone graft characteristics on the mechanical behavior of the lumbar spine. Journal of Biomechanics, 2002, 35(4): 491–497

Belytschko T B, Andriacchi T P, Schultz A B, Galante J O. Analog studies of forces in the human spine: computational techniques. Journal of Biomechanics, 1973, 6(4): 361–371

Belytschko T, Kulak R F, Schultz A B, Galante J O. Finite element stress analysis of an intervertebral disc. Journal of Biomechanics, 1974, 7(3): 277–285

Kuslich S D, Ulstrom C L, Michael C J. The tissue origin of low back pain and sciatica: A report of pain response to tissue stimulation during operations on the lumbar spine using local anesthesia. Orthopedic Clinics of North America, 1991, 22(2): 181–187

Linde F. Elastic and viscoelastic properties of trabecular bone by a compression testing approach. Danish Medical Bulletin, 1994, 41(2): 119–138

Mizrahi J, Silva M J, Keaveny T M, Edwards W T, Hayes W C. Finite-element stress analysis of the normal and osteoporotic lumbar vertebral body. Spine, 1993, 18(Suppl 14): 2088–2096

Fowlkes W Y, Creveling C M. Engineering methods for robust production design using Taguchi method in technology and product development. Reading: Addison-Wesley Longman, 1995

Rao R S, Kumar C G, Prakasham R S, Hobbs P J. The Taguchi methodology as a statistical tool for biotechnological applications: a critical appraisal. Biotechnology Journal, 2008, 3(4): 510–523

Dar F H, Meakin J R, Aspden R M. Statistical methods in finite element analysis. Journal of Biomechanics, 2002, 35(9): 1155–1161

Chao C K, Hsu C C, Wang J L, Lin J. Increasing bending strength of tibial locking screws: Mechanical tests and finite element analyses. Clinical Biomechanics (Bristol, Avon), 2007, 22(1): 59–66

Chao C K, Lin J, Putra S T, Hsu C C. A neurogenetic approach to a multiobjective design optimization of spinal pedicle screws. Journal of Biomechanical Engineering, 2010, 132(9): 091006

Chen L H, Tai C L, Lee D M, Lai P L, Lee Y C, Niu C C, Chen WJ. Pullout strength of pedicle screws with cement augmentation in severe osteoporosis: a comparative study between cannulated screws with cement injection and solid screws with cement pre-filling. BMC Musculoskeletal Disorders, 2011, 12(1): 33

Hou S M, Hsu C C, Wang J L, Chao C K, Lin J. Mechanical tests and finite element models for bone holding power of tibial locking screws. Clinical Biomechanics (Bristol, Avon), 2004, 19(7): 738–745

Hsu C C, Chao C K, Wang J L, Lin J. Multiobjective optimization of tibial locking screw design using a genetic algorithm: Evaluation of mechanical performance. Journal of Orthopaedic Research, 2006, 24(5): 908–916

Hsu C C, Lin J, Chao C K. Comparison of multiple linear regression and artificial neural network in developing the objective functions of the orthopaedic screws. Computer Methods and Programs in Biomedicine, 2011, 104(3): 341–348

Hsu W H, Chao C K, Hsu H C, Lin J, Hsu C C. Parametric study on the interface pullout strength of the vertebral body replacement cage using FEM-based Taguchi methods. Medical Engineering & Physics, 2009, 31(3): 287–294

Hsu W H, Hsu C C, Chao C K, Tsai Y H, Hsu H C. Analysis of the compressive strength and subsidence of a vertebral body cage with Taguchi methods. Journal of the Chinese Institute of Engineers, 2010, 33(4): 541–550

Lin C L, Yu J H, Liu H L, Lin C H, Lin Y S. Evaluation of contributions of orthodontic mini-screw design factors based on FE analysis and the Taguchi method. Clinical Biomechanics (Bristol, Avon), 2010, 43(11): 2174–2181

Yang K, Teo E C, Fuss F K. Application of Taguchi method in optimization of cervical ring cage. Journal of Biomechanics, 2007, 40(14): 3251–3256

Mitchell TM, Carbonell T J, Michalski R S, eds. Machine Learning: A Guide to Current Research. Norwell: Kluwer Academic Publishers, 1986

Cybenko G. Approximation by superpositions of a sigmoidal function. Mathematics of Control, Signals, and Systems, 1989, 2(4): 303–314

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nassau, C.J., Litofsky, N.S. & Lin, Y. Analysis of spinal lumbar interbody fusion cage subsidence using Taguchi method, finite element analysis, and artificial neural network. Front. Mech. Eng. 7, 247–255 (2012). https://doi.org/10.1007/s11465-012-0335-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-012-0335-2