Abstract

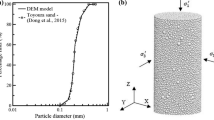

A modified discrete element method (DEM) with rolling effect taken into consideration is developed to examine macroscopic behavior of granular materials in this study. Dimensional analysis is firstly performed to establish the relationship between macroscopic mechanical behavior, mesoscale contact parameters at particle level and external loading rate. It is found that only four dimensionless parameters may govern the macroscopic mechanical behavior in bulk. The numerical triaxial apparatus was used to study their influence on the mechanical behavior of granular materials. The parametric study indicates that Poisson’s ratio only varies with stiffness ratio, while Young’s modulus is proportional to contact modulus and grows with stiffness ratio, both of which agree with the micromechanical model. The peak friction angle is dependent on both inter-particle friction angle and rolling resistance. The dilatancy angle relies on inter-particle friction angle if rolling stiffness coefficient is sufficiently large. Finally, we have recommended a calibration procedure for cohesionless soil, which was at once applied to the simulation of Chende sand using a series of triaxial compression tests. The responses of DEM model are shown in quantitative agreement with experiments. In addition, stress-strain response of triaxial extension was also obtained by numerical triaxial extension tests.

Similar content being viewed by others

References

Lignon S, Laouafa F, Prunier F, et al. Hydro-mechanical modelling of landslides with a material instability criterion. Geotechnique, 2009, 59(6): 513–524

Fu Z, Li J. Strength softening models of soil and its application in rainfall-induced landslide simulation. Theor Appl Mech Lett, 2013, 3(4): 042002

Cundall P A, Strack O D L. A discrete numerical model for granular assemblies. Geotechnique, 1979, 29(1): 47–65

Ng T T. Particle shape effect on macro- and micro-behaviors of monodisperse ellipsoids. Int J Numer Anal Methods Geomech, 2009, 33(4): 511–527

Salot C, Gotteland P, Villard P. Influence of relative density on granular materials behavior: DEM simulations of triaxial tests. Granular Matter, 2009, 11(4): 221–236

Azéma E, Radjai F, Saussine G. Quasistatic rheology, force transmission and fabric properties of a packing of irregular polyhedral particles. Mech Mater, 2009, 41(6): 729–741

Ji S. Probability analysis of contact forces in quasi-solid-liquid phase transition of granular shear flow. Sci China-Phys Mech Astron, 2013, 56(2): 395–403

O’Sullivan C. Particulate Discrete Element Modelling: A Geomechanics Perspective. New York: Taylor & Francis, 2011. 449–494

Thornton C. Numerical simulation of deviatoric shear deformation of granular media. Géotechnique, 2000, 50(1): 43–53

Jiang M J, Leroueil S, Konrad J M. Insight into strength functions in unsaturated granulate by DEM analysis. Comput Geotech, 2004, 31(6): 473–489

Wang Y H, Leung S C. A particulate scale investigation of cemented sand behaviour. Canadian Geotech J, 2008, 45(1): 29–44

Utili S, Nova R. DEM analysis of bonded granular geomaterials. Int J Numer Anal Methods Geomech, 2008, 32(17): 1997–2031

Jiang M J, Yan H B, Zhu H H, et al. Modeling shear behaviour and strain localization in cemented sands by two-dimensional distinct element method analyses. Comput Geotech, 2011, 38(1): 14–29

Jiang M J, Yu H S, Harris D. Bond rolling resistance and its effect on yielding of bonded granulates by DEM analyses. Int J Numer Anal Methods Geomech, 2006, 30(8): 723–761

Jiang M J, Yin Z Y. Analysis of stress redistribution in soil and earth pressure on tunnel lining using the discrete element method. Tunnelling Underground Space Tech, 2012, 32: 251–259

Mitchell J K, Soga K. Fundamentals of Soil Behavior. New York: Wiley, 2005. 87–91

Radjai F, Dubois F. Discrete-element Model of Granular Materials. New York: Wiley, 2011. 123–124

Mollon G, Zhao J. Fourier-voronoi-based generation of realistic samples for discrete modelling of granular materials. Granular Matter, 2012, 14(5): 621–638

Iwashita K. Mechanics of Granular Materials: An Introduction. Rotterdam: Taylor & Francis, 1999. 178–183

Iwashita K, Oda M. Rolling resistance at contacts in simulation of shear band development by dem. J Eng Mech, 1998, 124(3): 285–292

Iwashita K, Oda M. Micro-deformation mechanism of shear banding process based on modified distinct element method. Powder Technol, 2000, 109(1): 192–205

Jiang M, Yu H S, Harris D. A novel discrete model for granular material incorporating rolling resistance. Comput Geotech, 2005, 32(5): 340–357

Wang D, Zhou Y. Discrete element simulation of localized deformation in stochastic distributed granular materials. Sci China Ser G-Phys Mech Astron, 2008, 51(9): 1403–1415

Plassiard J P, Belheine N, Donze F V. A spherical discrete element model: Calibration procedure and incremental response. Granular Matter, 2009, 11(5): 293–306

Belheine N, Plasslard J P, Donze F V, et al. Numerical simulation of drained triaxial test using 3d discrete element modeling. Comput Geotech, 2009, 36(1–2): 320–331

Duriez J, Darve F, Donze F V. A discrete modeling-based constitutive relation for infilled rock joints. Int J Rock Mech Mining Sci, 2011, 48(3): 458–468

Scholtès L, Donzé F V, Khanal M. Scale effects on strength of geomaterials, case study: Coal. J Mech Phys Solids, 2011, 59(5): 1131–1146

Estrada N, Taboada A, Radjaï F. Shear strength and force transmission in granular media with rolling resistance. Phys Rev E, 2008, 78(2): 021301

Šmilauer V, Catalano E, Chareyre B, et al. Yade Documentation. The Yade Project (http://yade-demorg/doc/), 2010

Li G X. 3d Constitutive Relationships for Soils and Experiment Validation (in Chinese). Dissertation for Doctoral Degree. Beijing: Tsinghua University, 1985. 34–43

Liao C L, Chang T P, Young D H, et al. Stress-strain relationship for granular materials based on the hypothesis of best fit. Int J Solids Struct, 1997, 34(31–32): 4087–4100

PFC3D UsM. Itasca Consulting Group. Inc, Minneapolis, USA, 2005

Kozicki J, Donze F V. Yade-open dem: An open-source software using a discrete element method to simulate granular material. Eng Comput, 2009, 26(7–8): 786–805

Weatherley D. Esys-particle v2. 0 User’s Guide. 2009

Scholtès L, Chareyre B, Nicot F, et al. Micromechanics of granular materials with capillary effects. Int J Eng Sci, 2009, 47(1): 64–75

Wang X L, Li J C. Numerical triaxial apparatus and application. Appl Mech Mater, 2013, 353: 3251–3255

Voivret C, Radjai F, Delenne J Y, et al. Space-filling properties of polydisperse granular media. Phys Rev E, 2007, 76(2): 021301

Agnolin I, Roux J N. Internal states of model isotropic granular packings. I. Assembling process, geometry, and contact networks. Phys Rev E, 2007, 76(6): 061302

Jiang M J, Konrad J M, Leroueil S. An efficient technique for generating homogeneous specimens for DEM studies. Comput Geotech, 2003, 30(7): 579–597

Chareyre B, Villard P. Discrete element modeling of curved geosynthetic anchorages with known macro-properties. J Eng Mech-ASCE, 2005, 131(7): 197–203

Gilabert F A, Roux J N, Castellanos A. Computer simulation of model cohesive powders: Influence of assembling procedure and contact laws on low consolidation states. Phys Rev E, 2007, 75(1): 011303

Tan Q M. Dimensional Analysis: With Case Studies in Mechanics. Heidelberg: Springer, 2011. 7–16

Jop P, Forterre Y, Pouliquen O. A constitutive law for dense granular flows. Nature, 2006, 441(7094): 727–730

MiDi GDR. On dense granular flows. Eur Phys J E, 2004, 14(4): 341–365

Hicher P Y, Chang C S. Evaluation of two homogenization techniques for modeling the elastic behavior of granular materials. J Eng Mech-ASCE, 2005, 131(11): 1184–1194

Cambou B, Jean M, Radjaï F. Micromechanics of Granular Materials. London: Wiley Online Library, 2009. 101–147

Chang C S, Liao C L. Estimates of elastic modulus for media of randomly packed granules. Appl Mech Rev, 1994, 47(1): 197–206

Li G X. Advanced Soil Mechanics (in Chinese). Beijing: Tsing University Press, 2004. 117–119

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, X., Li, J. Simulation of triaxial response of granular materials by modified DEM. Sci. China Phys. Mech. Astron. 57, 2297–2308 (2014). https://doi.org/10.1007/s11433-014-5605-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-014-5605-z