Abstract

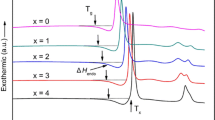

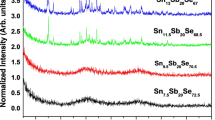

Pd80+x Si20−x (x = 0, 1, and 2) binary metallic glasses with the diameter ranging from 7 to 8 mm were prepared by a combination of fluxing and water quenching or air cooling. Thermal analysis results show that with increasing Si content, the glass transition temperature T g, the initial crystallization temperature T x and the onset crystallization temperature T p of Pd-Si binary glassy alloys increase. Moreover, the supercooled liquid region reaches 61 K. It indicates that Pd-Si binary alloys possess large glass forming ability, which can be greatly improved by fluxing treatment.

Similar content being viewed by others

References

Klement W, Willens R H, Duwez P. Non-crystalline structure in solidified gold-silicon alloys. Nature, 1960, 187: 869–870

Turnbull D. Under what conditions can a glass be formed? Contemp Phys, 1969, 10: 473–488

Greer A L. Metallic glasses. Science, 1995, 267: 1947–1953

Kui H W, Greer A L, Turnbull D. Formation of bulk metallic glass by fluxing. Appl Phys Lett, 1984, 45(6): 615–616

Inoue A, Zhang T, Masumoto T. Al-La-Ni amorphous alloys with a wide supercooled liquid region. Mater Trans JIM, 1989, 30(12): 965–972

Kim S G, Inoue A, Masumoto T. High mechanical strengths of Mg-Ni-Y and Mg-Cu-Y amorphous alloys with significant supercooled liquid region. Mater Trans JIM, 1990, 31(11): 929–934

Inoue A, Zhang T, Masumoto T. Zr-Al-Ni amorphous alloys with high glass transition temperature and significant supercooled liquid region. Mater Trans JIM, 1990, 31(3): 177–183

Inoue A. High-strength bulk amorphous-alloys with low critical cooling rates. Mater Trans JIM, 1995, 36: 866–875

Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater, 2000, 48: 279–306

Johnson W L. Bulk glass-forming metallic alloys: Science and technology. MRS Bull, 1999, 24: 42–56

Wang W H, Dong C, Sheck C H. Bulk metallic glasses. Mater Sci Eng, 2004, R44: 24–89

Wang D, Li Y, Sun B B, et al. Bulk metallic glass formation in the binary Cu-Zr system. Appl Phys Lett, 2004, 84: 4029–4031

Xu D, Lohwongwatana B, Duan G, et al. Bulk metallic glass formation in binary Cu-rich alloy series-Cu100−x Zrx (x = 34, 36, 38.2, 40 at%) and mechanical properties of bulk Cu64Zr36 glass. Acta Mater, 2004, 52: 2621–2624

Tang M B, Zhao D Q, Pan M X, et al. Binary Cu-Zr bulk metallic glass. Chin Phys Lett, 2004, 21: 901–903

Yao K F, Ruan F. Pd-Si binary bulk metallic glass prepared at low cooling rate. Chin Phys Lett, 2005, 22: 1481–1483

Pu J, Wang J F, Xiao J Z, et al. Formation of Pd82Si18 bulk metallic glass and its crystallization. J Huazhong Univ Sci Tech, 2003, 31: 69–72

Yao K F, Ruan F, Yang Y Q, et al. Superductile bulk metallic glass. Appl Phys Lett, 2006, 88: 122106

Xia L, Li W H, Fang S S, et al. Binary Ni-Nb bulk metallic glasses. J Appl Phys, 2006, 99: 026103

Wang J G, Choi B W, Nieh T G, et al. Crystallization and nanoindentation behavior of a bulk Zr-Al-Ti-Cu-Ni amorphous alloy. J Mater Res, 2000, 15(3): 798–807

Greer A L, Castellero A, Madge S V, et al. Nanoindentation studies of shear banding in fully amorphous and partially devitrified metallic alloys. Mater Sci Eng A, 2004, 375–377: 1182–1185

Schuh C A, Nieh T G. A nanoindentation study of serrated flow in bulk metallic glasses. Acta Mater, 2005, 51: 87–99

Greer A L, Walker I T. Transformations in primary crystallites in (Fe,Ni)-based metallic glasses. Mater Sci Forum, 2002, 386–388: 77–88

Tang C G, Li Y, Zeng K Y. Characterization of mechanical properties of a Zr-based metallic glass by indentation techniques. Mater Sci Eng A, 2004, 384(1–2): 215–223

Lu Z P, Liu C T. Glass forming criterion for various glass systems. Phys Rev Lett, 2003, 91: 115505

Inoue A, Nishiyama N. Extremely low critical cooling rates of new Pd-Cu-P base amorphous alloys. Mater Sci Eng, 1997, A226–228: 401–405

Chen N, Yao K F, Ruan F. Influence of flux treatment on the glass forming ability of Pd-Si binary alloy. J Univ Sci Tech Beijing, 2007, 14(suppl 1): 4–7

Chen N, Yao K F, Ruan F. The influence of cooling rate on the hardness of Pd-Si binary glassy alloys. Mater Sci Eng, 2007, A473: 274–278

Yao K F, Zhang C Q. Fe-based bulk metallic glass with high plasticity. Appl Phys Lett, 2006, 90: 061901

Hong S Y, Guo W H, Kui H W. Metastable liquid miscibility gap in Pd-Si and its glass forming ability (III). J Mater Res, 1999, 14: 3668–3672

Lee K L, Kui H W. Phase separation in undercooled molten Pd80Si20 (I). J Mater Res, 1999, 14: 3653–3662

Lee K L, Kui H W. Crystallization of undercooled liquid spinodals (II). J Mater Res, 1999, 14: 3663–3667

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Basic Research Program of China (Grant No. 2007CB613905) and the National Natural Science Foundation of China (Grant Nos. 50671050 and 50431030)

Rights and permissions

About this article

Cite this article

Yao, K., Chen, N. Pd-Si binary bulk metallic glass. Sci. China Ser. G-Phys. Mech. As 51, 414–420 (2008). https://doi.org/10.1007/s11433-008-0051-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-008-0051-4