Abstract

Purpose

In Poland, coal is the main fuel used for heat production. Innovative clean coal technologies, which include underground coal gasification (UCG), are widely developed. This paper presents the analysis results of life cycle assessment (LCA) and material flow analysis (MFA) of using synthesis gas from UCG for heat production. The paper presents the results of a comparative analysis of MFA and LCA for four variants of heat production, which differed in the choice of gasifying agent and heat production installations.

Methods

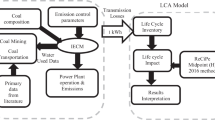

Environmental analysis was made based on LCA with ReCiPe Midpoint and ReCiPe Endpoint H/A method, which allowed to analyse of different categories of the environmental impact. LCA was performed based on the ISO 14040 standard using SimaPro 8.0 software with Ecoinvent 3.1 database (Ecoinvent 2014). Umberto NXT Universal software was used to develop MFA for heat production. LCA analyses included hard coal from a Polish mine and synthesis gas obtained in the experimental installations in the Central Mining Institute in Poland.

Results and discussion

MFA performed for technology of utilizing gases from UCG have made it possible to visualize materials and energy flow between different unit processes in the whole technological chain. Moreover, the analyses enabled identification of unit processes with the largest consumption of raw materials, energy and the biggest emissions into the environment. It has been shown that the lowest environmental burden is attributed to the technology, which uses high-pressure chamber with gas turbine in which the synthesis gas from UCG is burned and oxygen was a gasifying agent. Analysis of LCA results showed that the major environmental burden includes greenhouse gas (GHG) emission and the fossil fuels depletion. GHG emission results primarily from the direct emission of CO2 from gas combustion for heat production and electricity consumption used in gasifying agents preparation phase.

Conclusions

In order to increase the environmental efficiency of heat production technology using UCG, the most important activity to be considered is limitation of dust-gas emissions, including primarily CO2 removal process and efficiency increase of the installation, which is reflected in the reduction of coal consumption. It is important to highlight that this is the first attempt of MFA and LCA of heat production from UCG gas. Since no LCA has ever been conducted on the heat production from underground coal gasification, this study is the first work about LCA of the heat production from UCG technology. This is the first approach which contains a whole chain of unconventional heat production including preparation stages of gasifying agents, underground coal gasification, gas purification and heat production.

Similar content being viewed by others

1 Introduction

Technology of underground coal gasification (UCG) is regarded as one of clean coal technologies. UCG may provide an alternative to the conventional coal mining technology previously used in mines where deposits, due to technical and economic reasons, are not suitable to be exploited with traditional mining methods. Underground coal gasification technology, in comparison to other methods of processing this raw material for energy, is very attractive from the point of view of investment costs, as it does not require building expensive infrastructure. An additional advantage of UCG technology is its environmental aspect, such as the lack of solid waste (ash and slag) and lower emission of pollutants into the air (Kapusta and Stańczyk 2011; Kapusta et al. 2013; Smolinski et al. 2012; Smolinski et al. 2013). The scientific papers present an analysis of the aspects of UCG process impact on the environment, including major environmental problems such as pollution of groundwater. The product of the underground coal gasification is synthesis gas, which can be used in the production of heat, energy and in the chemical industry. The use of gas from UCG to generate electricity and heat arises mainly from its low calorific value. The calorific value of process gas depends on a number of factors, among others, the quality of coal and type of gasifying agents (Friedmann 2011). Due to the costs, air or air enriched with oxygen is most commonly used for the gasification. In the case of coal gasification with oxygen only, the costs of the process significantly rise, yet gas with higher calorific value is obtained, but also containing higher levels of carbon dioxide. In the Central Mining Institute in Poland, UCG studies are carried out on a laboratory and pilot scale targeted to obtain gas with a high hydrogen content (Kapusta and Stańczyk 2011; Kapusta et al. 2013; Smolinski et al. 2012; Smolinski et al. 2013). Detailed description and an overview of the underground coal methods and application possibilities of this technology are shown in the papers (Yang et al. 2008; Liu et al. 2009; Olateju and Kumar 2013; Żogała 2014; Janoszek et al. 2013). The composition of the gas from UCG differs depending on the type of gasified coal, gasifying agent used, the existing pressure and temperature. In order to use the resulting synthesis gas derived from UCG to produce heat, it must be purified (Gil and Mocek 2013). The gas from underground coal gasification, in spite of low calorific value can provide alternative fuel gas, the conversion of which in the combustion chamber allows a stream of heat to be generated. This heat can be used for heating purposes, hot water production, or be converted to the form of electricity in the steam turbine system (Gil and Mocek 2013). Scant attention is paid to the environmental aspects of UCG use towards the heat production in subject literature. Environmental, technical, and economical analysis of coal gasification processes was shown by Man et al. (2014). In recent years, life cycle assessment for heat and energy systems has been widely studied (Zarębska and Dzikuć 2013; Lewandowska et al. 2015; Pang et al. 2015; Ghafghazi et al. 2011). In literature, life cycle inventory of electricity production was presented by Dubreuil (2001) and energy consumption in steel production were published by Bieda (2011, 2012a, b) and Burchart-Korol (2013a). However, so far, there is a lack of papers related to the analysis of LCA for heat production from UCG. In the reference literature, there are a few papers on life cycle assessment of the process of underground coal gasification to produce electricity, and it has been demonstrated there that underground gasification technology is effective and there is low environmental impact (Saliyeva et al. 2014; Hyder et al. 2014; Ag Mohamed et al. 2011; Blinderman 2004; Blinderman and Jones 2002; Hyder et al. 2012). Hyder et al. (2014) demonstrated that the technology for the production of electricity using underground coal gasification is characterized by lower greenhouse gas emissions, as compared to conventional coal combustion. In the paper Torres et al. (2014), it has been found that efficient sustainable management of underground coal gasification process is possible to be accomplished. Previous results of LCA assessments for underground coal gasification for electricity production presented in the reference literature refer only to the emission of greenhouse gases. MFA of electricity production on the basis of the underground coal gasification to date was presented in the paper (Czaplicka-Kolarz et al. 2014a). MFA enables visualization of materials and energy flow and an identification of the unit processes with the highest consumption of raw materials and energy, and emissions of pollutants into the environment. Until now, the authors evaluated LCA and eco-efficiency of coal gasification technologies for electricity production system (Burchart-Korol et al. 2013; Czaplicka-Kolarz et al. 2014b). So far, there are no papers in the subject literature concerning LCA of heat production from UCG, scarce literature refer only to LCA analysis of electricity production and mainly focus on the greenhouse gases emissions.

The objective of this paper was to assess the potential environmental impact of heat production technology from gas obtained from underground coal gasification using MFA and LCA technique. This article for the first time presents MFA and LCA analysis results. In this paper, the results of analysis for four scenarios of heat production, based on coal gasification process, have been shown.

2 Materials and methods

2.1 Goal and scope of analysis

The purpose of this paper was MFA and LCA analysis of heat production technology from underground coal gasification: from gasifying agents preparation, coal gasification, through purification of gas obtained from UCG to the stage of heat production. Comparative analyses were performed of four scenarios depending on the type of gasifying agents (oxygen, air) and the installations of gas combustion (boiler, turbine). For comparison purposes, all analyses were related to the same functional unit. The function of the system is heat production from UCG. The functional unit was 1 GJ of the produced heat. The system boundary comprises all unit processes from the preparation of gasifying agents, through coal gasification, gas purification to obtaining the heat (Fig. 1).

2.2 Data inventory

To perform MFA and LCA analyses of considered scenarios of heat production from underground coal gasification, mainly the data from experiments and tests carried out in Poland within the framework of the national project: “Development of coal gasification technology for high production of fuels and energy” funded by the National Center for Research and Development under the Strategic Programme for Research and Development titled: “Advanced energy generation technologies” were used. On the basis of this data, a model layout for heat production using underground coal gasification was developed. So far, there have been no analytical results published in reference literature concerning the production of heat from UCG. LCA analyses take into account data on national coal and synthesis gas obtained in experiments by the Central Mining Institute (Stańczyk 2015). In accordance with the project guidelines, two types of synthesis gas combustion installations were used. The analysis was performed for the power of 50 MWt, for the two devices, in which gas from UCG can be burned: for a chamber, in which fuel is burned under atmospheric pressure (boiler), as well as for high-pressure chamber with gas turbine (turbine). Detailed description of the analysed solutions is presented in the papers (Gil and Mocek 2013; Gil and Mocek 2013). The operation of these installations is related to heat losses. Part of the heat supplied to the combustion chamber in the form of fuel is used for the production of steam, this is the so-called usable heat, the rest constitutes a loss. The most significant heat loss is the chimney loss. MFA and LCA analyses were performed for two types of gas derived from hard coal gasification with parameters provided in Table 1. The parameters of synthesis gas taken into consideration in the analyses are presented in Table 2. Process gas G1 was formed during hard coal gasification, where air formed the gasifying agent. The process gas G2 was formed by coal gasification, where the gasification factor was oxygen. Table 3 shows the characteristics of the analysed scenarios. A life cycle inventory (LCI) of each scenario of heat production is shown in Table 4, where the CK means gas combustion in the boiler while CT stands for gas combustion in the turbine.

All raw materials, fuel and additives, and electricity required to operate the processes were considered in the system boundaries, while intermediate products (internal flow) were excluded from the analysis. LCA included all external data used in the heat production process, the emissions and wastewater.

2.3 MFA method

MFAs consisted in developing models of material flow network using Umberto software, on the basis of which Sankey diagram was developed. Material flow networks consist of transitions, places and arrows. Graphic forms of the elements are presented in Fig. 2.

Each of the elements of a flow network plays a different function there (Wohlgemuth et al. 2006):

-

Transitions—unit processes; in a flow network they are presented as squares, materials and energy are processed/transformed in transitions, they represent unit processes in a given system.

-

Places—three types of places are distinguished: input, output, and connections. Input and output are presented as circles in a flow network. Input characterizes everything that enters a given system from the environment/outside. Output is everything that leaves the system and goes outside to the environment. Input and output are the places which link the system with the environment. In flow networks, connections are presented as two concentric circles. Connections are located between transitions, they are “buffers/reserves”, which are successively used and replenished by the flow. They link individual unit processes in an analysed system if there is no storage stage between the unit processes. The output of one unit process is matched by the input of another unit process, or unit processes.

-

Arrows—they connect places and transitions, building the structure of a material and energy flow network. They show the flow, and how much material and energy is transported between places and transitions.

2.4 LCA method

Attributional life cycle assessment (LCA) was used to assess the potential environmental burdens of the analysed scenarios for heat production. The LCA was conducted following the requirements of the ISO 14044:2006 International Standards. The four stages of the LCA applied in the paper included goal and scope determination, system boundary analysis; inventory analysis of inputs and outputs; life cycle impacts assessment; and interpretation. The life cycle assessment was carried out using the LCA software package SimaPro v.8.0 (Pre Consultants B.V) and the Ecoinvent 3.1 database (Ecoinvent 2014) within the program. The study performed an environmental evaluation according to the ReCiPe method. The results of the LCIA methods were calculated and the main sources of environmental burdens were identified. The primary objective of the ReCiPe Midpoint and ReCiPe Endpoint H/A method (Goedkoop et al. 2013) is to transform the long list of life cycle inventory results presented in a study into a limited number of indicator scores, which express the relative severity of an environmental impact category. In ReCiPe, the indicators are determined at two levels with 18 midpoint indicators and three endpoint indicators. ReCiPe method allows for a quantitative assessment of the greenhouse gas emission, human health, resource consumption and other impact categories. The basic structure of the impact assessment method is comprised of characterization, damage assessment, normalization and weighting, the last three of which are optional according to the ISO standards. In this study, the LCIA (life cycle impact assessment) phase includes mandatory and optional elements.

3 Results and discussion

3.1 Results of material flow analysis

The MFA application allowed for the development of material flow network of heat production from UCG (Fig. 3). On the basis of the developed network model, flow analyses were performed in the form of Sankey diagrams for all analysed scenarios, so that inventoried input and output data converted into functional units are presented. Table 5 shows the main inventoried data for individual scenarios.

Figures 4, 5, 6, and 7 present material flow analysis (MFA) in the form of Sankey diagrams for the four model scenarios of using gas from UCG for heat converted into the functional unit, taking into account the unit processes:

-

Phase 1—preparation of gasifying agents

-

Phase 2—underground coal gasification

-

Phase 3—purification of gas from gasification

-

Phase 4—synthesis gas combustion for heat production

Based on the MFA results have been shown that CKG2 variant is characterized by the highest consumption of electricity. Variants, in which a turbine was used for heat production, are characterized by lower values of CO2 emissions. In variants in which G1 gas (gasifying agent—air) was used for the heat production, the coal consumption was much greater than in the case of G2 gas (gasifying agent—oxygen). Among the analysed technologies, the most considerable electricity consumption occurs in scenarios where the gasifying agent was oxygen, which is related to the preparation of the gasifying agents. Unit consumption of G2 gas is much lower than in the case of using G1 gas, it is associated with a high calorific value of G2 gas, which is 8 MJ/m3. Such high calorific value of gas is due to the use of oxygen as a gasifying agent.

3.2 Results of life cycle assessment

This is the first study to express heat production from UCG in terms of LCA. On the basis of the LCA analysis using ReCiPe Midpoint method for the model gas systems from UCG for heat production, environmental indicators were obtained in each impact category, as shown in Table 6.

On the basis of the characterization results, it cannot be specified in which categories the impact should be considered as significant, nor compare indicators for the various impact categories. Therefore, the next stage of the LCA analysis was normalization, which resulted in the relative significance of the environmental impact category compared to the impact of this type occurring in Europe. The results of LCA of analysed scenarios in normalization phase according to ReCiPe Midpoint method are shown in Table 7.

It was found that the most significant impact categories in the case of the analysed heat production technology systems based on the underground coal gasification includes fossil depletion, climate change, terrestrial acidification, human toxicity, freshwater eutrophication, freshwater ecotoxicity, marine ecotoxicity, particulate matter formation and photochemical oxidant formation. The next stage of the LCA was weighting of results. A set of indicators given in Table 8 was adopted. Table 9 shows the main factors that affect the various damage categories in accordance with the ReCiPe Endpoint H/A method.

Analysis of the results after normalization and weighing shows that total environmental indicator ReCiPe 2008 is affected mainly by the indicators in the category of greenhouse gas emissions and the depletion of fossil fuels. Emission of greenhouse gases is the impact category with the highest indicator for all the analysed variants, which in the case of the analysed technologies is connected primarily with CO2 emissions. Higher emissions of GHGs were found in the boiler rather than turbine gas combustion technology. This is primarily due to lower unit CO2 emissions for the variants where the gas turbine has been used. The highest consumption of fossil fuels was found in the variants, where G1 gas is used for heat production whereas the lowest in variants in which G2 gas is burned. Higher consumption of fossil resources occurs in gas combustion technology using the boiler rather than turbine for G2 gas, while for G1 gas the situation is reversed, but the difference amounts to only 3.26 kg oil eq. After the stage of normalization and weighting of the obtained results it was found that the lowest total value of the environmental impact indicator takes place in CTG2 variant, and the highest in CKG1. By comparing the indicators with respect to the combusted gases G1 and G2, it has been shown that the gas of lower calorific value G1, where air is gasifying agent, has the highest influence on the environment. In the case of heat production technology, where gas G1 was used, the highest unit consumption of coal and the highest consumption of purified gas was found. By comparing the environmental burden of the technology utilizing gases for heat production by means of different installations, it has been shown that the gas combustion systems with the use of a turbine have a lower impact on the environment in all impact categories. This is primarily due to lower unit coal consumption, lower unit consumption of synthesis gas and lower CO2 emissions than in the situation when the boiler was used. There was also much lower heat loss which increases the efficiency of the process.

Results of LCA analyses showed that the CKG2 variant is harmful to the environment to the greatest extent in all impact categories except for the impact of fossil fuels consumption. The results obtained for other variants are comparable, yet only in the case of the category—fossil fuel consumption, there are significant differences depending on the gasifying agent used. LCA analysis results obtained using weighting and normalization reflect the results obtained in the analysis of MFA. It has been shown that the least burden to the environment has CTG2 variant (gasification with oxygen, the turbine).

Additionally comparative assessment for heat production from natural gas and coal heating system was performed. Figure 8 shows the results of comparative LCA of heat production from UCG, natural gas and coal heating system taking into account the stages of normalization and weighting, divided into various damage categories: impact on human health, on the ecosystem and resources consumption.

The LCA analysis showed that Scenario CKG1 had a greater environmental impact than the other scenarios, natural gas and coal heating system. It was found that in the case of heat production from coal the highest impact on the environment occurred in the category of human health and in the case of heat production from natural gas the highest impact on the environment occurred in the category of resources. It also appeared that heat production from natural gas had a less impact than the other scenarios.

3.3 The sensitivity of the assessment results of environmental indicators resulting from the selected impact assessment perspective

An analysis of sensitivity using LCA methodology was carried out—the perspective of evaluating adverse effects on the environment arising from the installation life cycle. LCA stages of normalization and weighting, the performance of which is necessary to obtain a single eco-indicator, there is uncertainty of the results. Uncertainty is associated with weighting the damage impacts associated with human health, ecosystem and the use of resources. These weights are selected by an expert method, thus representing the views of science representatives concerning which environmental issues are considered the most important—protecting human health, species diversity and conservation of natural resources for future generations. There are three groups of weighting indicators based on a system of three averaged values of archetypal personalities:

-

individualist (I/A—individualist/average),

-

egalitarian (E/A—egalitarian/average)

-

and hierarchist (H/A—hierarchist/average).

Sets of normalization and weighting coefficients, created in this way, take into account the different points of view and can be used to analyse the sensitivity of the results. Taking into account different sets of coefficients in the sensitivity analysis helps to reduce uncertainty. As a default, in the analysis of the life cycle it is recommended to use hierarchist perspective (H/A), which takes into consideration mechanisms, models and the impacts widely accepted in the world. LCA analyses of model systems using UCG gas, the hierarchist perspective (H/A) was used. Figure 9 shows the results of a sensitivity analysis of the obtained indicators ReCiPe 2008 depending on the adopted perspective of evaluation: E/A, H/A, I/A. Brief characteristics of perspectives allow to understand their potential impact on the environmental impact assessment (Table 10):

-

Individualists (I/A) pursue a “business as usual” scenario, accept only those restrictions which have a sound scientific basis, they are science and society oriented, prefer a short-term perspective over the long-term one, and non-intervention policy with respect to nature.

-

Egalitarian attitude (E/A) is opposed—they are characterized by caution, in the case of doubt they take into account the potential impacts, they do not accept scientific and political organizations advice, nor the attitude that future problems can be avoided—they use long-term perspective. This attitude describes to the fullest extent possible burden, yet it is marked with very high uncertainty.

-

The hierarchists (H/A) perspective is the result of a compromise between the perspective of individuals and egalitarian attitude.

The sensitivity of the obtained results on the assessment perspective is high. The impact on the environment assessed from the egalitarian perspective is the highest—in this case, the assessment model takes into account all substances that can potentially contribute to environmental pollution. The environmental assessment from the perspective of individuals gives, in turn, the lowest indicators of environmental impact, because in this case the assessment model ignores all substances which activity has not been proved, and also assigns less weight to the use of resources, according to the assumption that the problem of resource depletion will be resolved in the future thanks to new technologies. Despite the fact that the differences in the obtained results are large, they have no significant effect on the comparison of the different variants of the technological chains of gasification process. The same variants have the lowest or the highest impact on the environment in each group of variants, regardless of the assessment perspective.

4 Conclusions

-

1.

Since no LCA has ever been conducted on the heat production from underground coal gasification, this study is the first work about LCA of the heat production from UCG technology.

-

2.

The results of LCA and MFA for the heat production from underground coal gasification have been presented in the reference literature for the first time.

-

3.

Carried out MFA analyses for the technology aimed at using gases from underground coal gasification enabled the visualization of material and energy flows between particular unit processes in the entire technology chain and the identification of the unit processes characterized by the highest consumption of raw materials and energy and the biggest emissions into the environment.

-

4.

Environmental analysis using LCA technique of model technology systems using gases obtained from the underground coal gasification allowed the evaluation of the potential environmental burdens in the technology life cycle

-

5.

The analysis of LCA results showed that the total indicator is affected mainly by the indicators in the category of greenhouse gas emissions and the depletion of fossil fuels. Greenhouse gas emission is primarily due to the direct emissions of CO2 from gas combustion for heat production and from electricity consumption. In the case of gasification, where oxygen is the gasifying agent, the consumption of fossil fuels is more than two times lower than in the case of gasification with air.

-

6.

The analysis of LCA has shown that the lowest environmental burden is characteristic for combustion technology of synthesis gas in a high-pressure chamber using a gas turbine, where oxygen was a gasifying agent. The gas turbine is a recommended installation to be used in the case of utilizing UCG gases with a view of heat production, taking into consideration the lowest environmental burden during the technology life cycle.

-

7.

The analyses made so far will be used to investigate eco-efficiency of heat production technology using underground coal gasification.

-

8.

Development of the life cycle inventory (LCI) of underground coal gasification technologies will be the direction for future research.

5 Recommendations and perspectives

-

1.

In order to increase environmental efficiency of heat production technology using UCG, the most important operation should be considered the reduction of dust and gas emissions, including in particular the process of limiting carbon dioxide emissions and increasing the overall efficiency of the installation, which is reflected in lower coal consumption.

-

2.

Prospective research will include the development of work related to the analysis of environmental efficiency using LCA technique for the complex heat production systems from UCG. Subsequent analyses will also involve economic aspects and eco-efficiency analysis of heat production technologies from UCG.

References

Ag Mohamed A, Batto SF, Changmoon Y (2011) Viability of underground coal gasification with carbon capture and storage in Indiana. Capstone Design, Bloomington School of Public and Environmental Affairs, Indiana University

Bieda B (2011) Life cycle inventory of energy production in ArcelorMittal steel power plant Poland S.A. in Krakow, Poland. Int J Life Cycle Assess 16:503–511

Bieda B (2012a) Life cycle inventory processes of the ArcelorMittal Poland (AMP) S. A. in Kraków, Poland—basic oxygen furnace steel production: a case study. Int J Life Cycle Assess 17:463–470

Bieda B (2012b) Life cycle inventory processes of theMittal Steel Poland (MSP) S. A. in Krakow—blast furnace pig iron production—a case study. Int J Life Cycle Assess 17:787–794

Blinderman MS (2004) Underground coal gasification for power generation: efficiency and CO2 emissions. In: Proceedings of ASME power

Blinderman MS, Jones RM (2002) The Chinchilla IGCC project to date: Underground coal gasification and environment. Paper presented at the 2002 gasification technologies conference, San Francisco USA

Burchart-Korol D (2013) Life cycle assessment of steel production in Poland: a case study. J Clean Prod 54:235–243

Burchart-Korol D, Krawczyk P, Śliwińska A, Czaplicka-Kolarz K (2013) Ocena ekoefektywności systemu produkcyjnego technologii naziemnego zgazowania węgla. Przem Chem 3:384–390 (in Polish)

Czaplicka-Kolarz K, Burchart-Korol D, Krawczyk P (2014a) Analiza wrażliwości ekoefektywności technologii produkcji energii w procesie opartym na naziemnym zgazowaniu węgla. Przem Chem 93:1910–1915 (in Polish)

Czaplicka-Kolarz K, Korol J, Ponikiewska K, Ludwik-Pardała M (2014b) Material and energy flow analysis (MEFA) of the unconventional method of electricity production based on underground coal gasification. J Sust Min 13:41–47

Dubreuil A (2001) Inventory for energy production in Canada. Int J Life Cycle Assess 6:281–284

Ecoinvent (2014) Ecoinvent database version 3.1, released on 8th July 2014

Friedmann SJ (2011) Underground coal gasification. Transformational Clean Fossil Technology, World Energy Council Houston, Texas Nov. 1, LLNL-PRES-449296

Ghafghazi S, Sowlati T, Sokhansanj T, Bi X, Melin S (2011) Life cycle assessment of base–load heat sources for district heating system options. Int J Life Cycle Assess 16:212–223

Gil I, Mocek P (2013) Termiczna konwersja gazu z podziemnego zgazowania węgla. Przegląd Gorniczy 2:116–122 (in Polish)

Goedkoop M, Heijungs R et al, ReCiPe 2008 (2013) A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level. ReCiPe Report, Ruimteen

Hyder Z, Ripepi NS, Karmis M (2012) Underground coal gasification in the central Appalachian region, USA: resource assessment. 22nd World Mining Congress and Expo, Istanbul Turkey, 11–16 September 2012

Hyder Z, Ripepi NS, Karmis M (2014) A life cycle comparison of greenhouse emissions for power generation from coal mining and underground coal gasification. Mitig Adapt Strat Glob Chang. doi:10.1007/s11027-014-9561-8

Janoszek T, Łączny MJ, Stańczyk K, Smoliński A, Wiatowski M (2013) Modelling of gas flow in the underground coal gasification process and its interactions with the rock environment. J Sust Min 12:8–20

Kapusta K, Stańczyk K (2011) Pollution of water during underground coal gasification of hard coal and lignite. Fuel 90:1927–1934

Kapusta K, Stańczyk K, Wiatowski M, Chećko J (2013) Environmental aspects of a field-scale underground coal gasification trial in a shallow coal seam at the Experimental Mine Barbara in Poland. Fuel 113:196–208

Lewandowska A, Noskowiak A, Pajchrowski Z (2015) Between full LCA and energy certification methodology—a comparison of six methodological variants of buildings environmental assessment. Int J Life Cycle Assess 20:9–22

Liu S, Wang Y, Zhao K, Yang N (2009) Enhanced-hydrogen gas production through underground gasification of lignite. Min Sci Technol 19:389–394

Mocek P, Gil I, Wodołażski A (2013) Wybrane zagadnienia projektowania instalacji oczyszczania produktów podziemnego zgazowania węgla. Przegląd Górniczy 2:99–106 (in Polish)

Olateju B, Kumar A (2013) Techno-economic assessment of hydrogen production from underground coal gasification (UCG) in Western Canada with carbon capture and sequestration (CCS) for upgrading bitumen from oil sands. Appl Energ 111:428–440

Pang M, Zhang L, Wang C, Liu G (2015) Environmental life cycle assessment of a small hydropower plant in China. Int J Life Cycle Assess 20:796–806

Saliyeva S, Menicucci J, Lettieri P. Simons S (2014) Life cycle assessment of underground coal gasification, 14th Annual Meeting Atlanta, https://aiche.confex.com. Accessed 15 May 2015

Smolinski A, Stańczyk K, Kapusta K, Howaniec N (2012) Chemometric study of the ex situ underground coal gasification wastewater experimental data. Water Air Soil Pollut 223:5745–5758

Smolinski A, Stańczyk K, Kapusta K, Howaniec N (2013) Analysis of the organic, contaminants in the condensate produced in the in-situ underground coal gasification process. Water Sci Technol 67:644–650

Stańczyk K (2015) Experience of central mining institute in underground coal gasification – research and pilot test in “KWK Wieczorek” mine, World Clean Coal Conference, Turkey & Eurasia http://www.fossilfuel.co.za/. Accessed 10 June 2015

Torres V, Atkins A, Singh R (2014) Assessment of an environmental sustainability index for the underground coal gasification, Process by Using Numerical Analysis, 2014 Coal Operators’ Conference, The University of Wollongong

Wohlgemuth V, Page B, Kreutzer W (2006) Combining discrete event simulation and material flow analysis in a component-based approach to industrial environmental protection. Environ Model Softw 21:1607–1617

Yang L, Zhang X, Liu S, Yu L, Zhang W (2008) Field test of large-scale hydrogen manufacturing from underground coal gasification (UCG). Int J Hydrog Energy 33:1275–1285

Zarębska J, Dzikuć M (2013) Determining the environmental benefits of life cycle assessment (LCA) on example of the power industry. Sci J Marit Univ Szczecin 34:97–102

Żogała A (2014) Critical analysis of underground coal gasification models—part I: equilibrium models – literary studies. J Sust Min 13:22–28

Acknowledgments

This paper is a part of the ongoing Research Task “Development of coal gasification technology for high production of fuels and energy” funded by the National Centre for Research and Development under the Strategic Programme for Research and Development titled: “Advanced energy generation technologies”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest. Research does not involve Human Participants and/or Animals.

Additional information

Responsible editor: Zbigniew Stanislaw Klos

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Burchart-Korol, D., Korol, J. & Czaplicka-Kolarz, K. Life cycle assessment of heat production from underground coal gasification. Int J Life Cycle Assess 21, 1391–1403 (2016). https://doi.org/10.1007/s11367-016-1102-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-016-1102-0