Abstract

Purpose

India is one of the fastest growing economies in the world. Energy is a critical input for socio-economic development, and its strategy aims at efficiency and security. To provide access to environmentally friendly energy resources, the national biofuel policy targets cellulosic feedstocks which necessitates analysing feedstocks using holistic approaches. This paper studies the life cycle impact of ethanol production from cellulosic agricultural feedstocks.

Methods

The difficulty of finding appropriate life cycle inventory data for the analysed biofuels in the Indian context is overcome by combining data from diverse sources such as journal articles, government reports and personal contact with farmers. Variation in these numbers across studies is captured by means of error bars. These data are used to calculate environmental sustainability metrics such as energy return on investment, life cycle greenhouse gas emissions and life cycle water use for each fuel. Biomass sources considered in this work include cellulose from wheat stalk, rice husk, sorghum stalk, sugarcane bagasse and cotton stalk. These results are compared with ethanol from molasses and sugarcane juice, which are the conventional approaches.

Results and discussion

Results of the analysis indicate that sorghum stalk is most attractive due to its high energy return on investment, low greenhouse gas emissions, and low water and land use. Ethanol from rice husk has relatively high water use and greenhouse gas emissions, but these are within the margin of variability of other fuels. Despite the attractiveness of sorghum stalk from the current analysis, it is not likely that this will become a major feedstock for cellulosic ethanol in India. This is because farmers value sorghum as an animal feed and may not be willing to convert it into ethanol.

Conclusions

This is the first life cycle study of Indian cellulosic biofuel pathways. The inventory data collected in this work is a novel contribution that should be useful for other studies. Findings from the analysis can help guide the decision-making process in the biofuel sector for India.

Similar content being viewed by others

1 Introduction

Volatility in oil prices, desire for self-sufficiency, and concern about environmental impacts are some of the reasons why much attention continues to be given to the search for alternative energy sources and technologies (Cai et al. 2011; Felix 2006). The development of biofuels as an alternative energy source has become an issue of increasing importance due to its potential of reducing greenhouse gas emissions worldwide (Gopalakrishnan et al. 2009; Yang et al. 2009). India is fifth in the world in terms of primary energy consumption but has only 0.5 % of global oil and gas resources with 16 % of the global population. The country accounts for 3.5 % of global commercial energy demand, which is fulfilled mainly by fossil fuel resources. These facts, combined with accelerating demand for transportation fuels, have encouraged the Indian government, like many governments all over the world to focus on the development of fuels from diverse sources, including those from biomass. Indian biofuel policy only suggests a target of blending 20 % biofuels, both for bio-diesel and bio-ethanol, by 2017. As in many other countries, this policy is driven by the desire for energy efficiency and security. This requires access to a mix of fuels that are environmentally friendly and economically feasible (Sukumaran et al. 2010; National policy on Biofuels 2009).

The opportunities, choices and risks relating to biofuel production vary considerably between different countries. Given its high population density and growing economy, India cannot afford to turn fertile cropland over to biofuel production (Phalan 2009). Thus, evaluating and understanding the sustainability of biofuels before their widespread adoption is a strong societal need (Fingerman et al. 2010). First-generation biofuels have received considerable criticism due to their impact on increasing food prices, their relatively low greenhouse gas (GHG) abatement capacity, their continuing need for significant government support and subsides, and their direct and indirect impacts on land use change and related greenhouse gas emissions (Harvey and Pilgrim 2011). Feedstocks that involve direct utilization of agricultural land will affect food security and cause indirect land-use change, while those that replace forests, wetlands or natural grasslands will increase emissions and damage biodiversity (Phalan 2009). Ethanol produced at a large scale from lignocellulosic raw materials is considered to be a promising alternative for next-generation automotive fuels. Drivers for governments to aggressively pursue lignocellulosic biofuel development are complex and multidimensional because this fuel pathway has the potential to address issues related to energy and food security, climate change, and domestic production. Presently, in India, ethanol demand for blending is mainly sourced from sugarcane molasses, but this is barely sufficient to meet the current demand. In addition, reduction in government subsidy on sugar increases the possibility of soaring ethanol prices. This motivates development of technologies for converting other raw materials such as lignocellulosic biomass into ethanol (Sukumaran et al. 2010). Commercialization of lignocellulosic ethanol is limited largely due to the lack of cost-effective processing technologies and the cost of enzymes. Although conversion of active agricultural lands to biofuel production is likely to adversely affect food security, it can be maintained for future generations along with optimal growth of bioenergy by using agro-industrial lignocellulosic waste as it is a by-product of crops (Kumar et al. 2009). India does not have surplus grains or other starchy biomass to spare for fuel applications; hence, competition for land use is intense due to depletion of existing fuel resources (Harvey and Pilgrim 2011).

Currently, India mandates use of 5 % ethanol blending in motor gasoline in ten states and three union territories, but implementation of this policy is subject to availability and market fluctuations (National Policy on Biofuels 2009). Biofuels are considered a substitute for petroleum-fuels, but to be viable, they should not depend heavily upon non-renewable resources (Felix 2006). More than 70 % of the needs of the country are met from imports of crude oil and natural gas. Demand for motor gasoline has been growing at an average annual rate of 7 % during the last decade, and it shows an increasing trend. The consumption of petrol for transportation needs (motor gasoline) is estimated to be 15.23 billion l for year 2008–2009, which implies an ethanol demand of about 1.5 billion l for blending. This demand is projected to be 2.2 billion l in 2017 (Sukumaran et al. 2010).

Decisions being made today regarding the management of resources will profoundly affect our economic and environmental future. Climate change and other stresses that are created due to human activities are limiting benefits from the services provided by nature. Major biofuel programs supported in the USA and other countries have raised the discussion about sustainability implications of biofuels, including the impact on wildlife, biodiversity, land use, air pollution and water resources (Mishra and Yeh 2011). To address sustainability issues, focus should be on multiple indicators such as energy, greenhouse gas emission, land and water. Motivation for such systems analysis of biofuels is to provide a platform for decision-making process as India has been pressing for renewable fuels. Life cycle studies of biofuels that analyse impact widely and can help in designing national policies for developing countries like India can be valuable but are not yet available. Lignocellulosic feedstock for biofuel production can fill the gap between demand and supply of sugarcane ethanol, but it needs to be analysed thoroughly to reduce the chance of shifting impacts outside the analysis boundary. Benefit of utilization of agro-industrial waste as feedstock is that it is less likely to trigger land use change that could exacerbate global warming and affect biodiversity (Searchinger et al. 2008; Mandade et al. 2015). This research aims to provide insight into the environmental sustainability of lignocellulosic tropical biofuels. To develop fuels that have a minimum life cycle environmental impact, it is equally important that researchers and policymakers focus on resource consumption over the life cycle along with climate change and other environmental impacts of fuel production and use.

Globally, many studies have been undertaken to assess net energy balance and net carbon balance of biofuels. Nguyen and Gheewala (2008) and Khatiwada and Silveira (2011) analysed life cycle impact of ethanol from molasses for Thailand and Nepal, respectively. Earlier studies focus on the potential of feedstocks and suitability of lignocellulosic biofuels in Indian context, but details about the environmental sustainability of feedstocks were not available (Sukharam and Pandey 2009). Tsiropoulos et al. (2014) compared LCA of ethanol from molasses in India with the ethanol from sugarcane juice in Brazil. The Confederation of Indian Industry (CII 2010) has estimated energy and carbon balances of biofuel production from Indian context. This article provides comprehensive insight by covering different aspects of sustainability as it includes life cycle energy, emission, water and land use.

This article provides original insight into the life cycle environmental impact and sustainability of lignocellulosic biofuels in the Indian context on the basis of different sustainability indicators that may be helpful for policy makers. Since life cycle inventory data for these products has not been readily available, compilation of this inventory in a useful form for life cycle analysis is among the contributions of this work. The structure of this paper is as follows. The next section describes the methodology, including data sources, analysis boundary, allocation methods and the description of the metrics used in the analysis. This is followed by the calculated values of various metrics and their comparison with other studies. Finally, insight about sustainability is discussed based on calculated metrics along with scope for improving various phases of the life cycle. It is expected that this analysis will guide selection among lignocellulosic feedstocks while considering their sustainability in the Indian context. Results of this work are relevant to devising the biofuel energy policy for any developing nation.

2 Methodology

The fuel pathways considered in this work include the conventional approach for making ethanol in India, which is from sugarcane molasses. In this approach, sugarcane juice is converted into sugar, while remaining molasses are converted into ethanol. The cellulosic residue called bagasse is usually burned for heat or electricity. This approach avoids food-fuel conflict since it converts waste into fuel. Direct conversion of sugarcane juice into ethanol is also included in this work, as that is the approach used in Brazil and some other countries. These are existing technologies. Emerging technologies considered in this work convert cellulose into ethanol. The sources of cellulose considered are agricultural residues of rice husk, sorghum stalk, wheat straw and cotton stalk.

Estimated ethanol production potential for the analysed feedstocks is given in Table 1 assuming availability of 50 % of the feedstock for the year 2008–2009, based on collection efficiency and other applications of lignocellulosic waste. The numbers in this table are calculated from the existing data of feedstock availability and estimates of ethanol production determined from feedstock composition.

2.1 Scope and boundary of analysis

This study considers three phases of biofuel production process in its “cradle to gate” boundary: feedstock production, transportation of feedstock to process site and conversion of feedstock to ethanol, as shown in Fig. 1. The feedstock production phase includes fuels or energy-intensive material inputs such as fertilizers, herbicides, seed, diesel fuel, and electricity for irrigation, machinery and labour used for agriculture. The transportation phase includes moving of agricultural residues from farm to the process site by truck. The conversion process stage consists of various inputs that are needed for conversion of the bio feedstock to fuel such as lime, water, ammonia, diesel, cellulose and sulphuric acid. These data are obtained from the NREL life cycle inventory, resulting in the assumption that the cellulose to ethanol conversion technology does not change between the USA and India (Kadam 2002).

2.2 Data sources and assumptions

Obtaining relevant data for the selected life cycles was among the challenges addressed in this work, since efforts to compile life cycle inventory data for India are very recent. Furthermore, the relevant data are scattered across diverse sources, or simply not available in the open literature. Data from various sources are not always consistent in terms of the reported variables. For example, fertilizer data is available in only one dataset, while information about inputs such as diesel are reported in multiple datasets, as can be seen from Table S9 in the Electronic Supplementary Material.

Data for the farming phase were collected from different sources such as journal articles, Ministry of Statistics, Ministry of Agriculture, India Stat database and personal communication with farmers. Details about each source are available in the Electronic Supplementary Material. Farming data has wide spatial and temporal variation across the country. Data used in this study is from multiple sources that may cover multiple spatial and temporal scales. Its variability is represented by the mean, median, mode, high and low values, and error bounds in the graphs represent variability between studies as opposed to uncertainty in an individual study. Water requirement data for each dataset is not available for the crops considered in the analysis. But, water requirement data for crops are available in the range from low to high input per hectare. It is assumed that water used for irrigation is directly proportional to crop yield. Accordingly, water data is allocated to low, mean and high values of crop yield (Indiastat 2012). Distance of transportation of agro-residue from farm to factory is estimated to be 50-km roundtrip. As crop residues are the by-products, inputs such as energy and water need to be allocated between the main crop and its residue as described below.

2.3 Allocation

Allocation has been one of the most discussed challenges in LCA. It is the act of distributing the responsibility for inputs and outputs in the life cycle between multiple products. This concept is extremely important for bioenergy systems where multiple products are common. The effect of allocation on outcomes is of crucial importance to LCA as a decision support tool (Luo et al. 2009). This study considers three allocation methods based on energy, mass and economic value. Each method has its advantages and disadvantages, and the choice of allocation procedure depends on the goal of the study. The approach of allocation by displacement is often used and is recommended in the ISO standardized LCA approach. It relies on information about conventional processes that may be displaced by using by-products of the process being analysed. Unfortunately, since this allocation approach requires additional inventory information about processes that would be displaced, difficulty in getting such inventory data for India prohibits use of this approach.

One common allocation in this study is between the desired agricultural product and lignocellulosic biomass residue. For sugarcane crop, allocation is between three products: sugar, bagasse and molasses. For other crops such as wheat, rice and sorghum, cotton allocation is between desired crop and lignocellulosic biomass residue. It is difficult to allocate agricultural inputs to the main product and its residue. Today, agricultural residue may have a smaller value, but increasing demand of transportation fuel and extensive research on cellulosic biofuel technologies is likely to increase the demand and monetary value of agricultural waste. Consequently, use of different allocation approaches gives broader picture of future implication of the policy decisions. Mass allocation is on the basis of the amount of matter in the main product and residues generated in a hectare of land. The basis for energy allocation is the fuel value of the main agricultural product and its residue. Allocation based on economic value is between the crop residue and main agricultural products on the basis of Rs/Tonne of respective products and were calculated on a per hectare basis. Energy-based allocation is used at the ethanol conversion process between the main product fuel ethanol, and the coproducts electricity and biogas. Allocated input energy for fuel ethanol is used for energy return on investment (EROI) calculations.

2.4 Sensitivity analysis

As the cellulosic ethanol technology is still developing, uncertainties are present at each stage, particularly in the agricultural phase where the cellulosic feedstocks are grown. Ethanol yield is calculated on the basis of feedstock composition. For the processing stage, it is assumed that practical yield of ethanol per dry metric tonne (MT) of feedstock is 70 % of theoretical yield. Data variation in the farming phase is due to differences in yield of crop residues as a result of respective resource inputs. Variation in yield with local soil, weather, region and time is captured through diversity of the data used. In most of the feedstock, it is observed that resource inputs are directly proportional to yield of respective crop. Yield of crop residues is calculated based on the crop to residue ratio present in the literature (Purohit et al. 2006).

3 Metrics analysed

Numerous technologies and resources have been proposed as partial solutions to our declining fossil energy stocks, and several criteria have been used to analyse energy production technologies and alternatives. The need for metrics that reflect the multidimensionality of the system is widely acknowledged (Hammerschlag 2006). In assessing possible replacements for oil and natural gas, each alternative presents unique trade-offs between energy quantity, energy quality, and other inputs and impacts such as land, water, labour and environmental health. The metrics calculated in this work are the energy return on investment, greenhouse gas emissions, water withdrawal and land use, as described in the rest of this section.

3.1 EROI

Energy return on investment (EROI) is the ratio of the energy or fuel value delivered by a process to the fossil energy used directly and indirectly in the life cycle to convert the feedstock into the product. This has been the most used metric to compare energetic competitiveness of alternative fuels and accounts for only fuel value. EROI > 1 indicates that the product provides more fuel value to society than what it has consumed to produce the fuel. For ethanol, this quantity tells us how well the processes being analysed leverage their non-renewable energy inputs to deliver biomass-based energy (Mubako and Lant 2008).

EROI is always greater than zero, since energy produced and non-renewable energy used in the processing are both positive numbers (Hammerschlag 2006). This metric considers non-renewable energy and energy-related inputs consumed in the various stages of the ethanol production process. Energy return on investment (EROI) analysis provides a useful approach for examining disadvantages and advantages of different fuels and also offers the possibility to look into the future in ways that markets seem unable to do (Hall et al. 2009). Present analysis focuses on only the primary fossil energy consumption in the life cycle.

3.2 Life cycle GHG emission

In a GHG balance, emissions of the three most important greenhouse gases, CO2, CH4 and N2O, must be accounted for over the entire life cycle of the bioenergy system. These gases can be emitted directly or indirectly over the fuel production cycle and are responsible for the effect of increasing temperature in the lower atmosphere. This effect is quantified by using global warming potentials (GWPs) expressed as CO2 equivalents (Cherubini 2010; Macedo et al. 2008). Crop-based biofuels, especially those grown in the USA, dominate the literature, and most show a small negative GHG balance (Phalan 2009).

Life cycle analysis of GHG balance is complex, and inclusion or exclusion of co-products, processes behind processes and land use change impacts (direct and indirect) can all have a considerable influence on results (Martín et al. 2011). The biofuels production chains are divided in three processes: (i) biomass production or cultivation, which involves emissions from fuel used for agricultural processes, electricity used for irrigation processes, fertilizers and chemicals, etc. The emission factors for respective inputs which are used in biomass production are taken from literature (ii) transport of the bioenergy crops to the conversion plant, which includes fuel used for transport (iii) emissions from conversion of bioenergy crops to biofuels including inputs used such as NH3, diesel, cellulose, H2SO4 and fuels for processing. Estimation of life cycle GHG emissions was based on a litre of ethanol production. This metric helps to evaluate and compare the life cycle GHG performance of various lignocellulosic bio-energy systems using a consistent set of system boundaries (Guinée et al. 2009). Details about the emission factors for various inputs and other calculations are in the Electronic Supplementary Material.

3.3 Life cycle water use

Biofuel production at a large scale requires a considerable amount of water resources, and this water–energy nexus is not always taken into account. Despite the increase of biofuel production and the amount of research about this issue, the potential effects of associated water consumption have not been rigorously analysed, particularly in the Indian context. Many studies of water resource impacts of biofuel production only consider uses at the biorefinary while ignoring the agricultural water consumption and therefore do not fully characterize the life cycle effect of biofuels on water resources (Fingerman et al. 2010). As biofuel production increases, a growing need exists to understand and mitigate potential impacts to water resources, primarily those associated with the agricultural stages of the biofuel life cycle (Elena and Esther 2010; Powers et al. 2009).

This study computes life cycle water use by considering farming and processing phases for biofuel production from various feedstocks. It gives an overview of life cycle water use per litre of ethanol production from the selected feedstocks. The replacement of fossil energy with bioenergy generates the need for detailed information on water requirements since such a substitution may not be viable if the source is too water intensive (Gerbens-Leenes et al. 2009). The major uses of water are in both the agricultural and industrial phases of biofuel production.

Two types of consumption are considered in this analysis: agricultural water use including irrigation and rain water, and industrial or bio refinery consumption for processes such as cooling and incorporation into finished products (Macedo et al. 2008). Though water availability and requirement vary with space and time, it is assumed that irrigation is directly proportional to crop yield and water resource input allocated accordingly to crop yield which is described in the Electronic Supplementary Material. The results of this study are based on estimates of freshwater requirements in crop production obtained by integrating data from several sources.

3.4 Land use

Many life cycles of biofuel production do not account for land use changes that can result in unexpected surprises in the future (Searchinger et al. 2008). Decisions about how to use land need to consider many different factors like climatic conditions, energy-saving potential, reduction in GHG emissions, possible alternatives for energy production and need for other human activities besides energy production (Stoeglehner and Narodoslawsky 2009; Harvey and Pilgrim 2011). Populous countries need feedstocks that are land efficient and should not have a negative effect on the food supply (Kumar et al. 2009). Land utilization should justify the benefits of biofuels while evaluating the associated environmental and socioeconomic impacts. Scientific communities have been discussing and debating whether restricting the development of biofuel crops to avoid the conflicts among food production, biofuel production, and the environment (Cai et al. 2011; Yang et al. 2009).

Since agriculture is by far the largest contributor to land use, other steps in the life cycle are not included in this calculation. Land used per litre of ethanol production for each agro-industrial feedstock is computed, and effect of allocation method is determined.

4 Results

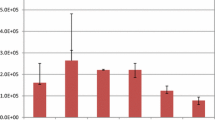

Results for the selected bioethanol pathways aim to highlight comparative life cycle environmental impact in Indian context. The resulting insight is expected to be useful for improving engineering and life cycle design, determining corporate strategy and supporting national policy. As discussed in Sect. 2, the life cycle inventory itself is a novel contribution of this work. Data has been collected from various resources described in detail in the Electronic Supplementary Material. Embodied energy values of some of the major inputs to the farming phase for all cellulosic feedstocks are shown in Fig. 2. Large variability in the inputs is due to collection of data from various regions of the country for different crops. Variations are captured by calculating mean, high and low value inputs. For rice crop electricity, consumption shows large variability as the electricity consumption varies according to the region and the nature of its water supply. Consumption of fertilizers is more for the sugarcane crop as compared to other feedstocks.

4.1 Life cycle EROI

The energy return on investment for lignocellulosic ethanol life cycles considered in this work ranges from 1.59 to 8 under different allocation approaches (Fig. 3). In general, economic value allocation shows higher EROI than mass and energy allocation due to the smaller relative economic value allocation of biomass residue as compared to its mass or energy values. Sorghum stalk shows highest life cycle energy return on investment among all lignocellulosic biomass feedstocks considered. Farming phase consumes major portion of life cycle energy consumption. This is larger than the EROI of the current commercial approach of producing ethanol from molasses and comparable to the EROI for ethanol production from sugarcane juice for an Indian context (Mandade et al. 2015). Among cellulosic ethanol life cycles, EROI for sugarcane bagasse and cotton stalk look most attractive, followed by rice husk and wheat stalk. All the life cycles of feedstocks considered in this work look more attractive than American corn-based ethanol, which has EROI from 0.84 to 1.65, as listed in the Electronic Supplementary Material. This is low due to high energy inputs in the farming phase. EROI for sugarcane-based ethanol for Brazil is 8.4 which is higher because of high yield of sugarcane crop (Kim and Dale 2005; Pimentel and Patzek 2005). Further comparison of EROI for various feedstock from India and other countries is given in the Electronic Supplementary Material in Table S16.

4.2 Life cycle GHG emissions

Life cycle GHG emission for lignocellulosic biofuel shown in Fig. 4 indicates that ethanol from rice husk has the highest emission. This emission varies from 0.13 to 1.8 kg of CO2 eq. per litre of ethanol and is mainly due to use of fertilizers, pesticides and electricity in the farming operations. The large variability is due to difference in yield of rice husk per hectare. GHG emission from other life cycles considered in this work, except sorghum, is within their margins of error. Mass allocation shows higher GHG emission than energy and economic value allocation for most of the feedstocks. Sorghum stalk feedstock shows lowest GHG emission among all other lignocellulosic feedstocks. Sugar-based feedstock like sugarcane juice for India the values varies from 0.39 to 0.61 kg of CO2 eq. per litre of ethanol produced (Mandade et al. 2015).

These results are comparable to those for other ethanol studies. For example, Macedo et al. reports life cycle GHG emission for sugarcane juice to ethanol 0.401–0.436 kg of CO2 eq. per litre of ethanol for Brazil (Macedo et al. 2008). MacLean and Spatari report GHG emissions for corn to ethanol process 1.8 while for switch grass 0.31–0.63 kg of CO2 eq. per litre of ethanol production (MacLean and Spatari 2009). For municipal solid waste, Kalago et al. estimate life cycle GHG emissions that are 0.18 kg of CO2 eq. per litre of ethanol. Reported life cycle GHG emission of sugarcane-based ethanol 0.461–0.572 kg of CO2 per litre of ethanol in Brazil, while corn-based ethanol ranges 1.39–1.45 for USA. GHG emissions for sugarcane molasses-based ethanol for India estimated in the range from 0.07 to 0.5 kg of CO2 eq. per litre of ethanol for different allocation approaches (Kalogo and Habibi 2007; Oliveira et al. 2005).

4.3 Life cycle water use

Life cycle water consumed per litre of ethanol is shown in Fig. 5. From this figure, sorghum stalk seems to be most efficient in using water, which should not be surprising since it can grow in relatively arid conditions. Sugarcane juice to ethanol process shows far higher water consumption for the production of ethanol than sugarcane bagasse feedstock due to the high water use in growing sugarcane and due to less water allocated to sugarcane bagasse at the farming phase.

As rice crop requires a lot of water i.e. 900–2500 l/ha in agricultural phase, it is a less efficient feedstock than other lignocellulosic feedstocks that require 230–7150 l of water for production of 1 l of ethanol under different allocation approaches. Economic allocation shows comparatively less water use per litre of ethanol than mass and energy allocation methods. This is due to less economic value of biomass residue than desired product. Yang et al. estimated average water use per litre of ethanol ranges from 1830 to 2640 l for starchy feedstocks like maize, cassava and sweet potato, while for sugarcane crop, it is 1470 l in China (Yang et al. 2009). Gerbens-Leenes et al. computed global water footprint for ethanol from starchy crop which are in the range 2516–9812 l of water use while for sugar crop 1388–2516 l of water for production of 1 l of ethanol (Gerbens-Leenes et al. 2009). Dominguez-Fau et al. show water footprint for switch grass feedstock 1401 l/l of ethanol for USA which is comparable for wheat stalk and sorghum stalk in the present study, but former considers only evapotranspiration in the water footprint calculation. Average water footprint of ethanol (litres of water/litre of ethanol) for corn ethanol studies in USA ranges from 1174 to 1492 by Mubako and Lant (Dominguez-Faus et al. 2009; Mubako and Lant 2008).

4.4 Land use

Land used for feedstock production is a key factor in determining biofuel sustainability. The graph comparing land use for the fuels considered is in the Electronic Supplementary Material. One of the constraints to expand biofuel production to reduce our dependence on fossil fuels is due to limited amount of land available for producing energy crops. In this work, land use per litre of ethanol ranges from 0.33 to 20.54 m2 for considered lignocellulosic feedstocks under different allocation approaches. Land use for production of a litre of ethanol from sugarcane bagasse is comparatively smaller than other feedstocks considered in the current study. All the land use data show wide variability, with wheat stalk showing the most variability due to large variation in the crop yield. Yang et al. estimated land use per litre of ethanol production ranges from 2.93 to 4.75 m2 for starchy feedstocks and 1.9 m2 for sugarcane feedstocks for China (Yang et al. 2009).

5 Discussion

In a populous country like India, converting sugar- and starch-based crops into ethanol has been unattractive as these crops are used for food or fodder. But, growing concerns about energy security and climate change, along with abundant availability of cellulosic feedstocks, are encouraging the development of cellulosic or second-generation biofuels. Such decisions need to be supported by life cycle assessment, as has been the case in many other parts of the world. However, such studies are not yet available for India. This article presents original data and life cycle evaluation of energy use, greenhouse gas emissions, water use and land use for existing and emerging bioethanol technologies in India.

Results of this work indicate that ethanol from sorghum may have the smallest impact among the categories analysed, as indicated by its high EROI and low GHG emissions. However, most farmers in India grow sorghum for food and fodder for their cattle. Thus, diverting sorghum for fuel may result in fodder-fuel conflict that may be unsustainable. Among other cellulosic sources, rice husk, cotton stalk and wheat stalk are likely to be most readily available as agricultural residues. Bagasse to ethanol also looks attractive due to its land efficiency and high yield of sugarcane. However, bagasse is already used for its fuel value, so conversion to ethanol may not be feasible. In the present work, three methods were considered for the allocation between the main crop and residue to show the broader picture of the assessment. Economic value allocation seems to be most meaningful allocation methods amongst the considered methods. As the usefulness of the crop residue increases (after increase in the demand of biofuel), the economic value of the residues will increase in the future. Allocation by displacement should be explored in the future as data for displaced activities becomes available.

Selection of appropriate feedstocks for bioethanol needs consideration of other impact categories and better data for higher confidence in the results. It also needs careful planning by considering various bottlenecks in technologies such as the pre-treatment of biomass, enzymatic saccharification of the pre-treated biomass, and fermentation of the hexose and pentose sugars released by hydrolysis and saccharification. Each of these problems requires substantial research and development efforts for improved efficiency and process economics. Process conversion efficiency is still improving, because technology of conversion of cellulosic ethanol is still in its immature stage. These improvements will slowly decrease gross energy input over time, but no large, sudden changes are expected. Proper management and supply chain logistics issues should be handled for feedstock availability throughout the year. Gaining insight into sustainability requires use of methods such as energy and life cycle analysis that reduce the chance of shifting impacts outside the analysis boundary. Other technologies and feedstocks also need to be examined by means of life cycle studies. For reliable production of lignocellulosic ethanol from agricultural feedstocks, sufficient quantity of appropriate feedstock must be available along with facilities to convert feedstock to ethanol within a practical distance of the feedstock production area. Feedstock producers would have to be willing to produce energy crops and/or remove a portion of residues from their fields, and would have to do so in a sustainable manner (Moreira and Feijoo 2010).

Large variation in water and land use per litre of ethanol shows that there is need of proper resource utilization so that optimum yield can be achieved. Resolving the apparent “food versus fuel” conflict seems to be more a matter of making the right choices rather than hard resource and technical constraints. This analysis shows that even a populous country like India can have suitable options of agro industrial lignocellulosic waste if the agricultural and manufacturing systems adapt to produce food and biofuels. Although this is the most comprehensive sustainability analysis of lignocellulosic biofuels in Indian context, data used in the analysis has wide temporal and spatial variability. Uncertainty and variability in the data can be addressed by developing the database nationwide for bio feedstock. The quality of future LCAs can also be improved through better data availability. Information on water use for particular dataset also needs improvement due to being scarce and of questionable quality (Maclean and Maclean 2010).

The systems view and multiple indicators of environmental sustainability make the current study useful for decision makers and to guide energy policy. This study covers land and water use which are basic ecosystem services; hence, it helps in designing future policies which will avoid unexpected surprises. The approach of energy analysis used in this work, while appealing in many ways only considers fossil resources with fuel value. Other methods such as energy analysis can account for a wider array of resources, and their application to these biofuels provides complementary insight (Mandade et al. 2015). In addition, consequences and dynamics of decisions made by static life cycle models should also be considered.

References

Cai X, Zhang X, Wang D (2011) Land availability for biofuel production. Environ Sci Technol 45(1):334–339

Cherubini F (2010) GHG balances of bioenergy systems – overview of key steps in the production chain and methodological concerns. Renew Energy 35:1565–1573

Confederation of Indian Industry (CII), (2010) Report on Estimation of energy and carbon balance of biofuels in India

Dominguez-Faus R, Powers SE, Burken JG, Alvarez PJ (2009) The water footprint of biofuels: a drink or drive issue? Environ Sci Technol 43:3005–3010

Elena GC, Esther V (2010) From water to energy: the virtual water content and water footprint of biofuel consumption in Spain. Energy Policy 38:1345–1352

Felix ER (2006) Integrated energy, environmental and financial analysis of biofuel production from switchgrass, hybrid poplar, soybean and casterbean. M.S. University of Maryland, College Park

Fingerman KR, Torn MS, O’Hare MH, Kammen DM (2010) Accounting for the water impacts of ethanol production. Environ Res Lett 5:1–7

Gerbens-Leenes W, Hoekstra AY, Van der Meer TH (2009) The water footprint of bioenergy. Proc Natl Acad Sci 106(25):10219–10223

Gopalakrishnan G, Negri MC, Wang M, Wu M, Snyder SW, Lafreniere L (2009) Biofuels, land, and water: a systems approach to sustainability. Environ Sci Technol 43(15):6094–6100

Guinée JB, Heijungs R, Voet EA (2009) Greenhouse gas indicator for bioenergy: some theoretical issues with practical implications. Int J Life Cycle Assess 14:328–339

Hall CAS, Balogh S, Murphy DJR (2009) What is the minimum EROI that a sustainable society must have? Energies 2:25–47

Hammerschlag R (2006) Ethanol’s energy return on investment: a survey of the literature 1990−present. Environ Sci Technol 40:1744–1750

Harvey M, Pilgrim S (2011) The new competition for land: food, energy, and climate change. Food Policy 36:S40–S51

http://www.indiastat.com/default.aspx (accessed on Feb 10, 2012)

Kadam KL (2002) Environmental benefits on a life cycle basis of using bagasse-derived ethanol as a gasoline oxygenate in India. Energy Policy 30(5):371–384

Kalogo Y, Habibi S (2007) Policy analysis environmental implications of municipal solid waste-derived ethanol. Environ Sci Technol 41(1):35–41

Khatiwada D, Silveira S (2011) Greenhouse gas balances of molasses based ethanol in Nepal. J Clean Prod 19:1471–1485

Kim S, Dale BE (2005) Life cycle assessment of various cropping systems utilized for producing biofuels: bioethanol and biodiesel. Biomass Bioenerg 29:426–439

Kumar B, Hiremath RB, Balachandra P, Ravindranath NH (2009) Bioenergy and food security: Indian context. Energ Sustain Dev 13:265–270

Luo L, Voet E, Huppes G, Udo de Haes HA (2009) Allocation issues in LCA methodology: a case study of corn stover-based fuel ethanol. Int J Life Cycle Assess 14(6):529–539

Macedo IC, Seabra JEA, Silva JAR (2008) Greenhouse gases emissions in the production and use of ethanol from sugarcane in Brazil: the 2005/2006 averages and a prediction for 2020. Biomass Bioenerg 32(7):582–595

Maclean S, Maclean HL (2010) Characterizing model uncertainties in the life cycle of lignocellulose-based ethanol fuels. Environ Sci Technol 44:8773–8780

MacLean HL, Spatari S (2009) The contribution of enzymes and process chemicals to the life cycle of ethanol. Environ Res Lett 4(1):1–10

Mandade P, Bakshi BR, Yadav GD (2015) Ethanol from Indian agro-industrial lignocellulosic biomass—an energy evaluation. Technical Report

Martín M, Ahmetovi E, Grossmann IE (2011) Optimization of water consumption in second generation bioethanol plants. Ind Eng Chem Res 50:3705–3721

Mishra GS, Yeh S (2011) Life cycle water consumption and withdrawal requirements of ethanol from corn grain and residues. Environ Sci Technol 454:563–4509

Moreira MT, Feijoo G (2010) Comparative environmental performance of lignocellulosic ethanol from different feedstocks. Renew Sustain Energy Rev 7(1):2077–2085

Mubako S, Lant C (2008) Water resource requirements of corn-based ethanol. Water Resour Res 44(8):1–5

National Policy on Biofuels (2009) Govt. of India, Ministry of New and Renewable Energy, pp 1–18

Nguyen TLT, Gheewala SH (2008) Life cycle assessment of fuel ethanol from cane molasses in Thailand. Int J Life Cycle Assess 13:301–311

Oliveira MEDD, Vaughan BE, Rykyel EJ Jr (2005) Ethanol as fuel: energy, carbon dioxide balances, and ecological footprint. Bioscience 55(7):593–602

Phalan B (2009) The social and environmental impacts of biofuels in Asia: an overview. Appl Energy 86:S21–S29

Pimentel D, Patzek TW (2005) Ethanol production using corn, switchgrass, and wood; biodiesel production using soybean and sunflower. Nat Resour Res 14(1):65–76

Powers SE, Burken JG, Alvarez PJ (2009) The water footprint of biofuels: a drink or drive issue? Environ Sci Technol 43:3005–3010

Purohit P, Tripathi AK, Kandpal TC (2006) Energetics of coal substitution by briquettes of agricultural residues. Energy 31:1321–1331

Searchinger T, Heimlich R, Houghton RA, Dong F, Elobeid A, Fabiosa J, Tokgoz S, Hayes D, Yu TH (2008) Use of U.S. croplands for biofuels increases greenhouse gases through emissions from land-use change. Science 319:1238–1240

Stoeglehner G, Narodoslawsky M (2009) How sustainable are biofuels? Answers and further questions arising from an ecological footprint perspective. Bioresour Technol 100(16):3825–3830

Sukharam RK, Pandey A (2009) Bioethanol - Ethanol from Biomass. In: Biswas S, Basak PR, Kaushik N (eds) Bioprocesses and bioproducts: emerging trends. Report Technology Information Forecasting & Assessment Council (TIFAC), DST, New Delhi, pp 11–36

Sukumaran RK, Surender VJ, Sindhu R, Binod P, Janu KU, Sajna KV, Rajasree KP, Pandey A (2010) Lignocellulosic ethanol in India: prospects, challenges and feedstock availability. Bioresour Technol 101(13):4826–4833

Tsiropoulos I, Faaij APC, Seabra JEA, Lundquist L, Schenker U, Briois JF, Patel MK (2014) Life cycle assessment of sugarcane ethanol production in India in comparison to Brazil. Int J Life Cycle Assess 19(5):1049–1067

Yang H, Zhou Y, Liu J (2009) Land and water requirements of biofuel and implications for food supply and the environment in China. Energy Policy 37(5):1876–1885

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Shabbir Gheewala

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 1287 kb)

Rights and permissions

About this article

Cite this article

Mandade, P., Bakshi, B.R. & Yadav, G.D. Ethanol from Indian agro-industrial lignocellulosic biomass—a life cycle evaluation of energy, greenhouse gases, land and water. Int J Life Cycle Assess 20, 1649–1658 (2015). https://doi.org/10.1007/s11367-015-0966-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-015-0966-8