Abstract

Bauxite residue is an important by-product of the alumina industry, and current management practices do not allow their full valorisation, especially with regard to the recovery of critical metals. This work aims to test the efficiency of ion exchange resins for vanadium (V) removal and recovery from bauxite residue leachates at alkaline pH (11.5 and 13). As an environmental pollutant, removal of V from leachates may be an obligation of bauxite residue disposal areas (BRDA) long-term management requirements. Vanadium removal from the leachate can be coupled with the recovery, and potentially can be used to offset long-term legacy treatment costs in legacy sites. Kinetics studies were performed to understand the adsorption process. The rate kinetics for the V adsorption was consistent with the pseudo-first-order kinetic model, with a higher adsorption rate for pH 11.5 (1.2 min−1). Adsorption isotherm data fitted better to Freundlich equations than to the Langmuir model. The maximum adsorption capacity (Langmuir value q max) was greatest for pH 13 (9.8 mg V g−1 resin). In column tests, breakthrough was reached at 70 bed volumes with the red mud leachate at pH 13, while no breakthrough was achieved with the effluent at pH 11.5. In regeneration, 42 and 76 % of V were eluted from the resin with 2 M NaOH from the red mud leachate at pH 13 and 11.5, respectively. Further optimization will be needed to upscale the treatment.

Similar content being viewed by others

Introduction

Bauxite residue or red mud is a major by-product of the aluminium industry, with an annual global production of 150 million t (Evans 2016) and a total inventory of 2.7 billion t (Binnemans et al. 2013). The current best practice in the industry is disposal in engineered bauxite residue disposal areas or BRDA, increasingly using dry stacking methods with equipment such as Amphirols to aid dewatering of the mud in order to compact and consolidate the residue, and treatment of any leachates that are produced (Evans 2016; Power et al. 2011). Partial neutralization using seawater, carbonation using waste carbon dioxide from ammonia production and accelerated carbonation using intensive farming methods are also used as best management practises (Evans 2016). The leachates generated by bauxite residue are enriched in a range of metal and metalloid oxyanions, namely As, Cr, Mo, Ni and Ga, and can have vanadium (V) concentrations in the range of 1.2–15.6 mg L−1 (Burke et al. 2013; Czop et al. 2011; Mayes et al. 2011). Vanadium is typically mobile in bauxite residue leachate, as it is present in its pentavalent form (Burke et al. 2012, 2013), which is toxic and a possible human carcinogen (IARC 2006). The treatment of these alkaline leachates by conventional methods (acid dosing and active aeration) is expensive, especially if it is to be continued for many decades after site closure (Evans 2015). Furthermore, buffering of bauxite residue leachate does not efficiently remove vanadium from solution (Burke et al. 2013) due to the mobility of vanadate from hyperalkaline conditions through to circum neutral pH (Takeno 2005). As such, there is a key need to develop remedial tools for V removal from alkaline leachates. Where this removal can be coupled with options for the recovery of vanadium and other critical metals from these hyperalkaline leachates (pH 9–13), there may be considerable scope for offsetting long-term legacy treatment costs.

Different materials have been used for vanadium removal from waters and wastewaters. Adsorbents such as activated carbon (Sharififard and Soleimani 2015), high-area C-cloth electrodes (Afkhami and Conway 2002) and metal oxide adsorbents (Naeem et al. 2007) have been used at bench scale for vanadium removal. The current research on removal of vanadium from waters and wastewaters shows growing trends towards the development of new adsorbent materials, such as nanoscale iron oxide-hydroxide-impregnated activated carbon (Sharififard et al. 2016), bisphosphonate nanocellulose (Sirviö et al. 2016), chitosan films (Cadaval et al. 2016) and flakes (Padilla-Rodríguez et al. 2015). Simultaneously, the use of waste materials as absorbents is also being studied (Hu et al. 2014; Hua et al. 2015; Leiviskä et al. 2015).

Vanadium has a medium risk of supply shortage and a high political risk (Hunt and Kraus 2013). It is also considered critical for the development of green technologies (Naden 2013) and renewable energy production and storage (Viebahn et al. 2015). The largest producers are China, Russia and South Africa (USGS 2015). Vanadium is mostly used in ferrous and non-ferrous alloys (Song et al. 2014), as well as for catalysts in automobiles, and in the chemical and polymer industries (Keränen et al. 2013; Navarro et al. 2007). The current recovery methods from secondary sources are based on ion exchange (Huang et al. 2010; Keränen et al. 2013; Li et al. 2013; Nguyen and Lee 2013; Zeng et al. 2009; Zhao et al. 2010), solvent extraction (Barik et al. 2014; Kim et al. 2014) and bioleaching (Mirazimi et al. 2015). Although, ion exchange resins have been used previously for V recovery or removal, limited data exist on feed solutions with a pH higher than 10 (Huang et al. 2010), and none with bauxite residue leachate.

The aim of this study was to investigate the efficacy of a basic anion exchange resin for the removal and recovery of vanadium from synthetic bauxite residue leachate solutions. The impact of pH and different vanadium concentrations were tested in batch tests. Experiments with columns allowed assessing breakthrough in removal and the feasibility of recovering vanadium.

Materials and methods

Chemicals

Two different bauxite residue leachates were generated in the laboratory and tested—an operating BRDA leachate (pH 13) and a post-closure BRDA effluent (pH 11.5) (Gräfe et al. 2011). Both were made with bauxite residue recovered from the dyke breach of the Ajka (Hungary) impoundment (Lat 47° 05′ 20 N, Long 14° 29′ 43 E) in December 2010 (Burke et al. 2012). The samples were kept refrigerated and, before use, dried at 60 °C for 48 h, and disaggregated using a mortar and pestle. The bauxite residue had carbonated after collection, so to fabricate the operating BRDA leachate, it was mixed with 0.1 M NaOH in a liquid to solid (L/S) ratio of 20 for 24 h. Before the experiments, the leachate was vacuum-filtered (0.2 μm). The post-closure BRDA effluent resulted from the dilution of the operating BRDA leachate with deionized water (15 MΩ cm ELGA Purelab water) and then enriched with divanadium pentoxide (general purpose grade, Fisher Chemical) to get a V concentration of approximately 5 mg L−1 (Clune et al. 2015; Higgins et al. 2015). Table 1 shows the average composition of the synthetic bauxite residue leachates used in this study, which shows ratios of major ion and trace element enrichment similar to environmental samples from Ajka leachate albeit at slightly lower concentrations.

Table 2 presents the properties of the resin used in the experiments: Amberlite®IRA-400 chloride form (Sigma-Aldrich). Prior to use, the resin was washed with water until the supernatant became clear and colourless, and then soaked in deionized water for 6 h, with 5 wt.% NaOH solution for 4 h, and again washed with deionized water until the supernatant pH was in the range of 8–9 (Huang et al. 2010). The resin was consequently used in the hydroxide form.

Batch tests containing 10 g of wet resin in 150 mL of solution were conducted at room temperature (20 ± 1 °C) in conical flasks (250 mL) to investigate the rate of V removal from solution. The flasks were mixed using a magnetic stirrer at 150 rpm. Aqueous samples (10 mL) were taken after 1, 2, 3, 4, 5, 10, 15, 20, 25 and 30 min. To establish the adsorption isotherms, further batch tests were made with 20 mL of the bauxite residue leachates and 1, 5, 10, 20 and 50 g L−1 of the ion exchange resin, stirred at 150 rpm for 30 min in an orbital shaker.

Column experiments

Column experiments were conducted in ϕ1.8 × 35 cm acrylic (Plexiglas) tubes. Hydroxyl conditioned resin was wet-packed into the column. The resin bed was backwashed with 200 mL of deionized water, allowed to stand for 20 min, and then flushed with deionized water, before introduction the bauxite residue leachate enriched with V2O5 at a flow-rate of 6 mL min−1 (see Table 3 for details). The bauxite residue leachate was produced as described in “Chemicals” section. Samples of the column effluent were collected every 30 min and analysed to determine vanadium concentrations. After finishing the stock solution, the column was flushed with 200 mL of deionized water, and then eluted with 2 M NaOH (200 mL) at a flow rate of 6 mL min−1. The eluent was collected in 10 mL fractions.

Analyses

All aqueous samples (10 mL) were filtered (0.45 μm, MCE Membrane Millex HA) and preserved with HNO3 (Romil SpA™ Super Purity Acid). The analyses were made using a Varian inductively coupled plasma optical emission spectrometer (ICP-OES). A blank and standard suite were analysed every ten samples to check instrument calibration, and wavelengths were selected by standard methods (USEPA Method 200.7). The calibration curve was prepared with 1, 5 and 10 mg L−1 standards. The quality control was made with a certified reference material (CRM-ES AT-1529, lot number 1319108).

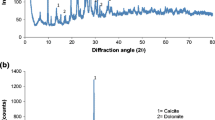

Data analysis

Hydrochemical data was analysed using the software PHREEQC Interactive v.3.1.7.9213 with the MINTEQ V4 database to determine the speciation of the most important elements and the stability of the solutions.

Results

Effect of contact time

Figure 1 shows the effect of contact time on the V removal in batch tests with the bauxite residue leachate (pH 13 and 11.5). There was a rapid initial adsorption of V, and both leachates reached a steady state within the 30-min test period. The bauxite residue leachate showed a fast removal in the first 5 min; equilibrium was reached immediately after. The pH 11.5 leachate showed the highest removal percentages (99.9 %) while the pH 13 leachate only reached 94 %.

The kinetics of V adsorption on the resin was studied from the time versus percent removal curves. The rate of adsorption was analysed using the model proposed by Lagergren (Eq. 1) (Hua et al. 2015):

where k 1 (min−1) is the adsorption rate constant, q t is the amount adsorbed at time t (min) and q e denotes the amount adsorbed at equilibrium, both in mg g−1. The rate constants (k 1) for the tested conditions were calculated from the linear least square method and are given in Table 4 along with the correlation coefficient (r 2). The best fits were obtained for pH 11.5 leachate (Table 4), with the adsorption rate being more than the double that of the pH 13 leachate.

Adsorption isotherms

The experimental data for V adsorption to the resin were fitted with Langmuir and Freundlich adsorption isotherms. The Langmuir isotherm assumes monolayer adsorption onto a surface with a finite number of identical sites, homogeneous distribution of sorption sites and sorption energies, without interactions between the sorbed molecules, and is described by:

where q e and C e are equilibrium concentrations of V in the adsorbed (mg g−1) and liquid phases (mg L−1), respectively. The Langmuir constants are the maximum adsorption capacity q max and b energy of adsorption.

On the other hand, Freundlich adsorption isotherm describes the adsorption equilibrium onto a heterogeneous surface with uniform energy (non-ideal adsorption), and is expressed by:

where q e and C e are the equilibrium concentrations of metal in the adsorbed (mg g−1) and liquid phases (mg L−1), respectively. K f and n are the Freundlich constants that are related to adsorption capacity and intensity, respectively.

Table 5 and Fig. 2 show the Langmuir and Freundlich isotherms fitting to the experimental data. The Freundlich isotherms fit the data better (r 2 > 0.99). The values of the Freundlich constant, 1/n were less than 1, which revealed that the exchange process is favourable. The Freundlich adsorption capacity constant K f at pH 11.5 is almost double than the one at pH 13.0. Maximum adsorption capacity values (q max) are higher at pH 13 (10 mg V g−1 resin).

Competing ions: removal efficiency

Bauxite residue leachates are enriched in a range of oxyanions that could compete with V on the ion exchange resins. Figure 3 shows the removal percentages of other elements also present in the bauxite residue leachates tested in the batch trials. In the operating BDRA neat residue leachate (pH 13), 100 % of P is removed, followed by 97.8 % of As, 94.6 % of S, 29.4 % of Si and 15.9 % of Al. This means that 1 g of resin removed 15.8 mg Al, 3.6 mg Si, 2.0 mg As, 0.4 mg P and 17.1 mg S. In the post-closure effluent and runoff (pH 11.5), similar results were obtained with higher removal percentages for S, Si and Al (100 % of P and As are removed, followed by 98.5 % of S, 84.9 % of Si and 41.3 % of Al). As the initial concentrations were lower at this pH, in this leachate 1 g of resin removed 1.7 mg Al, 10.2 mg Si, 0.05 mg As, 1.0 mg P and 3.1 mg S.

Column experiments

Figure 4 presents the breakthrough curves in the column experiments with the operating BRDA neat residue leachate (test 1, pH 13) and the post-closure effluent and runoff (test 2, pH 11.5). The breakthrough capacity (BTC) of a column is defined as the resin loading at the point when the effluent concentration is 10 % of C0 (Tavakoli et al. 2013). Complete “breakthrough” occurs when the column is exhausted, and the effluent concentration is equal to the influent concentration. In test 1, the breakthrough capacity was reached at 71 bed volumes (400 mL feed solution), and 75 % breakthrough was reached after ~330 bed volumes. In test 2, no breakthrough occurs after 300 bed volumes (Fig. 4). In both tests, no complete breakthrough was reached.

The V recovery when the columns were eluted with 2.0 M NaOH is shown in Fig. 5. In test 1, 42 % of vanadium was recovered with 2 bed volumes of NaOH, whereas in test 2 the V recovery was 76 % with 3.5 bed volumes. This value is consistent with others in the literature, that report an 82 % V desorption using 2 M NaOH (Hua et al. 2010).

Competing elements were also eluted with the NaOH (Fig. 6), especially in test 1 with the operating BRDA leachate (pH 13), where the concentrations of S were similar to vanadium. In test 1, most of the competing ions are eluted in the first 0.5 bed volumes, except S and Si, which has an almost constant concentration. The recoveries were 33 % of S, 28 % of As, 26 % of Si, 18 % of P and 0.2 % of Al. In test 2, the concentrations in the eluate are four times lower, and the peak in the elution curve is obtained at 1.2 bed volumes. In this test, Al is the competing element with higher concentrations, and 86 % is recovered.

Hydrochemical modelling

Table 6 presents the dominant V species under the tested conditions in the batch trials with the operating BRDA leachate and the post-closure effluent and shows that, in both, the dominant V solution species are hydrogen vanadate (HVO4 2−) and orthovanadate (VO4 3−). At pH 13, divanadate (V2O7 4−) is also important, while at pH 11.5, dihydrogen vanadate (H2VO4 −) is the third dominant species.

Discussion

The primary objective of the study was to test the efficacy of an anion exchange resin for the removal and recovery of vanadium from synthetic bauxite residue leachate solutions. The results show that the resin can be suitable for the removal of V at alkaline pH (11.5 and 13), and the rate at which the resin sorbs V can be predicted by a pseudo-first-order rate equation. Comparing the two feed solutions tested, the post-closure effluent showed a removal rate double that of the operating BRDA leachate and reached higher removal percentages (99.9 vs. 94.3 %). The Freundlich adsorption model had the best fit to the data, indicating that adsorption is non-ideal, and the value of 1/n means a favourable V removal. The Freundlich adsorption capacity constant K f was almost double for pH 11.5 compared to pH 13, indicating that V is more rapidly sorbed at lower pH. Two of the predominant V species at pH 11.5 (HVO4 2− and H2VO4 −) have lower charge density than VO4 3− and V2O7 4− (predominant at pH 13), and therefore, have a higher propensity to interact with the resin surfaces. Hence, sorption is enhanced. Contact time is a critical operational design parameter for water treatment technologies (PIRAMID Consortium 2003) and the short contact time required here shows promise for upscaling and practical application of ion exchange resins for V removal from bauxite residue leachates.

Results from the column tests show that the resin Amberlite® IRA-400 has 20 times less capacity with the simulated operating BDRA leachate (pH 13) than with the simulated post-closure effluent (pH 11.5). At pH 13, competing metal oxyanions, and Al and Si are in high concentrations, as well as the high concentration of OH− of the bauxite residue leachate (0.134 M in the operating BDRA leachate and 4 mM in the post-closure effluent), are likely to explain this lower efficacy. For optimal performance of the ion exchange resin, vanadium must bind more strongly to the resin than the displaced OH− and the competing ions present in the leachate. Published data suggests Amberlite® IRA-400 shows affinity for AsO4 3−>PO4 3−>SO4 2−>Cl−>OH− (Korkisch 1989; Tang et al. 2013). The results presented here (Fig. 3) are consistent with the resin affinity and show that simultaneously with hydrogen vanadates, other anions are being removed, which affects the resin capacity.

The ion exchange processes (exchange and regeneration) can be explained by the following equations, where ROH represents the resin in the hydroxide form:

In the removal of vanadium, hydrogen vanadate (HVO4 2−), the predominant form of V in the bauxite residue leachates, replaces the OH− attached to the exchanging sites of the resin (Eq. 4). All the competing ions identified (AsO4 3−, PO4 3− and SO4 2−) behave similarly, reducing the resin capacity by occupying the exchange sites. The resin regeneration involves the elution of the resin with a strongly basic solution, in this case, aqueous sodium hydroxide (NaOH 2 M). During regeneration, the trapped negative ions are flushed out and replaced by OH−, renewing the exchange capacity of the resin (Eq. 5).

Hydrochemical modelling in PHREEQC indicates some mineral precipitation is possible in these solutions, and that many of these precipitates include competing ions. Key solid phases are Ba3(AsO4)2 (saturation index SI 11.38); Ca3(PO4)2 (SI 0.59); Ca5(PO4)3OH (SI 11.92); Mg3Si2O5(OH)4 (SI 5.85); AlOOH (SI 0.28) and Mg2Si3O7.5OH:3H2O (SI 0.29). However, no visual evidence of precipitation was noted, and the removal of these phases from solution and their presence in the eluate in the batch and the column tests results suggests that the competing ions are exchanged in the resin. The presence of the competing elements in the eluate (Fig. 6) also points the need for more focused research to separate and purify vanadium for further recovery.

Even with the lower ionic strength influent of the post-closure effluent, there is always a fraction of V (2–3 %) that is not retained in the resins (Fig. 4). There are two possible explanations for these results—OH− ions in the leachate are eluting the vanadate ions from the resins, or the bed volume is insufficient for the removal and recovery of V.

Management of post-closure BRDA effluents is an increasingly prominent issue for the alumina industry (Clune et al. 2015; Higgins et al. 2015). The Ajka (Hungary) spill in 2010 highlighted some of the risks associated with BRDA leachates (Mayes et al. 2016), and there is increased R&D efforts to manage these issues given the potential longevity of alkaline leachate generation and metal(loid) enrichment (Buckley et al. 2016). The use of ion exchange resins to strip out elements that are problem pollutants and critical resources simultaneously would complement passive pH management efforts well. With the case of vanadium, this is particularly important given it appears to be only partially removed through precipitation from bauxite residue leachates during buffering to circum-neutral pH, contrary to Al and As (Burke et al. 2013). Further work is required to establish the viability of the resin for V recovery from bauxite residue leachate under environmental conditions and to test with higher bed volumes and configurations that could effectively remove competing ions (e.g. sequential removal using differing resins and multiple columns).

Conclusions

This study has shown that anion exchange resins can be used for metal removal and recovery from bauxite residue leachates in a highly alkaline pH range (up to 13). The results showed that using simulated undiluted bauxite residue leachate as feed solution limited the resin efficacy, due to the presence of competing ions, notably OH−. However, the resins are very effective at V removal for simulated post-closure bauxite residue disposal areas (BRDA) effluent, which has a lower ionic strength. Column experiments demonstrate that V is readily eluted from the resins in concentrations similar to some industrial process liquors which holds promise for recovery and recycling of V into downstream industrial processes. Further research is required to scale-up laboratory findings. This should include assessment pretreatments and optimisation of operating parameters, such as flow rate and bed height. This will help facilitate life cycle assessments of anion exchange resins as a potentially efficient and cost-effective option for both the treatment of bauxite residue leachates and the recovery of metals of critical importance such as vanadium.

References

Afkhami A, Conway BE (2002) Investigation of removal of Cr(VI), Mo(VI), W(VI), V(IV), and V(V) oxy-ions from industrial waste-waters by adsorption and Electrosorption at high-area carbon cloth. J Colloid Interface Sci 251:248–255

Barik SP, Park KH, Nam CW (2014) Process development for recovery of vanadium and nickel from an industrial solid waste by a leaching–solvent extraction technique. J Environ Manag 146:22–28

Binnemans K, Pontikes Y, Jones PT, Gerven TV, Blanpain B (2013): Recovery of rare earths from industrial waste residues: a concise review. In: Annelies Malfliet et al. (Hrsg.), Third international slag valorisation symposium - the transition to sustainable materials management. KU Leuven, Leuven, Belgium, pp. 191–205

Buckley R, Curtin T, Courtney R (2016): The potential for constructed wetlands to treat alkaline bauxite residue leachate: laboratory investigations. Environ Sci Pollut Res, 1–8

Burke IT, Mayes WM, Peacock CL, Brown AP, Jarvis AP, Gruiz K (2012) Speciation of arsenic, chromium, and vanadium in red mud samples from the Ajka spill site, Hungary. Environmental Science & Technology 46:3085–3092

Burke IT, Peacock CL, Lockwood CL, Stewart DI, Mortimer RJG, Ward MB, Renforth P, Gruiz K, Mayes WM (2013) Behavior of aluminum, arsenic, and vanadium during the neutralization of red mud leachate by HCl, gypsum, or seawater. Environmental Science & Technology 47:6527–6535

Cadaval TRS Jr, Dotto GL, Seus ER, Mirlean N, de Almeida Pinto LA (2016) Vanadium removal from aqueous solutions by adsorption onto chitosan films. Desalin Water Treat 57:16583–16591

Clune L, Fleming L, Higgins D, Curtin T, Courtney R (2015) Constructed wetlands for the remediation of bauxite residue disposal area leachate and run-off, 10th aluminium quality workshop conference. Perth, Western Australia

Czop M, Motyka J, Sracek O, Szuwarzyński M (2011) Geochemistry of the hyperalkaline Gorka pit lake (pH > 13) in the Chrzanow region, southern Poland. Water Air Soil Pollut 214:423–434

Evans K (2015): Successes and challenges in the management and use of bauxite residue. In: Pontikes Y (Hrsg.), Bauxite residue valorisation and best practices, Leuven, Belgium, pp. 53–60

Evans K (2016): The History, Challenges, and New Developments in the Management and Use of Bauxite Residue. J. Sustain. Metall., 1–16

Gräfe M, Power G, Klauber C (2011) Bauxite residue issues: III. Alkalinity and associated chemistry Hydrometallurgy 108:60–79

Higgins D, Courtney R, Curtin T, Clune L (2015): Use of constructed wetlands for treating BRDA leachate and run-off. In: Pontikes Y (Hrsg.), Bauxite Residue Valorisation and Best Practices, Leuven, Belgium, pp. 53–60

Hu Q, Paudyal H, Zhao J, Huo F, Inoue K, Liu H (2014) Adsorptive recovery of vanadium(V) from chromium(VI)-containing effluent by Zr(IV)-loaded orange juice residue. Chem Eng J 248:79–88

Hua T, Haynes RJ, Zhou YF, Boullemant A, Chandrawana I (2015) Potential for use of industrial waste materials as filter media for removal of Al, Mo, As, V and Ga from alkaline drainage in constructed wetlands—adsorption studies. Water Res 71:32–41

Huang J, Su P, Wu W, Liao S, Qin H, Wu X, He X, Tao L, Fan Y (2010) Concentration and separation of vanadium from alkaline media by strong alkaline anion-exchange resin 717. Rare Metals 29:439–443

Hunt A, Kraus GA (2013): Element recovery and sustainability. Royal Society of Chemistry

IARC (2006): IARC monographs on the evaluation of carcinogenic risks to humans. Vanadium pentoxide, 86. International Agency for Research on Cancer. IARC Working Group on the Evaluation of Carcinogenic Risks to Humans, 292 pp

Keränen A, Leiviskä T, Salakka A, Tanskanen J (2013) Removal of nickel and vanadium from ammoniacal industrial wastewater by ion exchange and adsorption on activated carbon. Desalin Water Treat 53:2645–2654

Kim H-I, Lee K-W, Mishra D, Yi K-M, Hong J-H, Jun M-K, Park H-K (2014) Separation and recovery of vanadium from leached solution of spent residuehydrodesulfurization (RHDS) catalyst using solvent extraction. J Ind Eng Chem 20:4457–4462

Leiviskä T, Keränen A, Vainionpää N, Al Amir J, Hormi O, Tanskanen J (2015) Vanadium(V) removal from aqueous solution and real wastewater using quaternized pine sawdust. Water Sci Technol 72:437–442

Li W, Zhang Y, Liu T, Huang J, Wang Y (2013) Comparison of ion exchange and solvent extraction in recovering vanadium from sulfuric acid leach solutions of stone coal. Hydrometallurgy 131–132:1–7

Mayes WM, Burke IT, Gomes HI, Anton ÁD, Molnár M, Feigl V, Ujaczki É (2016): Advances in understanding environmental risks of red mud after the Ajka spill Hungary. J. Sustain. Metall., 1–12

Mayes WM, Jarvis AP, Burke IT, Walton M, Feigl V, Klebercz O, Gruiz K (2011) Dispersal and atenuation of trace contaminants downstream of the Ajka bauxite residue (red mud) depository failure, Hungary. Environmental Science & Technology 45:5147–5155

Mirazimi SM, Abbasalipour Z, Rashchi F (2015) Vanadium removal from LD converter slag using bacteria and fungi. J Environ Manag 153:144–151

Mustafa S, Ahmad T, Naeem A, Shah KH, Waseem M (2010) Kinetics of chromium ion removal from tannery wastes using amberlite IRA-400 Cl− and its hybrids. Water Air Soil Pollut 210:43–50

Naden J 2013: Science and Implementation Plan. Security of Supply of Mineral Resources (SoS Minerals) Research Programme 2012–2017, Natural Environment Research Council

Naeem A, Westerhoff P, Mustafa S (2007) Vanadium removal by metal (hydr)oxide adsorbents. Water Res 41:1596–1602

Navarro R, Guzman J, Saucedo I, Revilla J, Guibal E (2007) Vanadium recovery from oil fly ash by leaching, precipitation and solvent extraction processes. Waste Manag 27:425–438

Nguyen TH, Lee MS (2013) Separation of molybdenum and vanadium from acid solutions by ion exchange. Hydrometallurgy 136:65–70

Padilla-Rodríguez A, Hernández-Viezcas JA, Peralta-Videa JR, Gardea-Torresdey JL, Perales-Pérez O, Román-Velázquez FR (2015) Synthesis of protonated chitosan flakes for the removal of vanadium(III, IV and V) oxyanions from aqueous solutions. Microchem J 118:1–11

PIRAMID Consortium (2003) Engineering guidelines for the passive remediation of acidic and/or metalliferous mine drainage and similar wastewaters. European Commission 5th Framework RTD Project no. EVK1-CT-1999-000021 “Passive in-situremediation of acidic mine / industrial drainage” (PIRAMID). University of Newcastle Upon Tyne, Newcastle Upon Tyne UK. 166 pp

Power G, Gräfe M, Klauber C (2011) Bauxite residue issues: I. Current management, disposal and storage practices. Hydrometallurgy 108:33–45

Sharififard H, Soleimani M (2015) Performance comparison of activated carbon and ferric oxide-hydroxide-activated carbon nanocomposite as vanadium(V) ion adsorbents. RSC Adv 5:80650–80660

Sharififard H, Soleimani M, Zokaee Ashtiani F (2016) Application of nanoscale iron oxide-hydroxide-impregnated activated carbon (Fe-AC) as an adsorbent for vanadium recovery from aqueous solutions. Desalin Water Treat 57:15714–15723

Sirviö JA, Hasa T, Leiviskä T, Liimatainen H, Hormi O (2016) Bisphosphonate nanocellulose in the removal of vanadium(V) from water. Cellulose 23:689–697

Song W-c, Li H, Zhu F-x, Li K, Zheng Q (2014) Extraction of vanadium from molten vanadium bearing slag by oxidation with pure oxygen in the presence of CaO. Trans Nonferrous Metals Soc China 24:2687–2694

Takeno N 2005: Atlas of Eh-pH diagrams, Geological Survey of Japan

USGS 2015: Vanadium, U.S. Department of the Interior. U.S. Geological Survey

Viebahn P, Soukup O, Samadi S, Teubler J, Wiesen K, Ritthoff M (2015) Assessing the need for critical minerals to shift the German energy system towards a high proportion of renewables. Renew Sust Energ Rev 49:655–671

Zeng L, Li Q, Xiao L (2009) Extraction of vanadium from the leach solution of stone coal using ion exchange resin. Hydrometallurgy 97:194–197

Zhao Z, Li X, Zhao Q (2010) Recovery of V2O5 from Bayer liquor by ion exchange. Rare Metals 29:115–120

Acknowledgments

The United Kingdom Natural Environment Research Council (NERC) funded this work through grants NE/K015648/1 and NE/L014211/1 under the Resource Recovery from Waste Theme. Many thanks to Bob Knight and Michael Thompson who performed the chemical analyses. Thanks also to Mark Anderson and Kim Rosewell for laboratory assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gomes, H.I., Jones, A., Rogerson, M. et al. Vanadium removal and recovery from bauxite residue leachates by ion exchange. Environ Sci Pollut Res 23, 23034–23042 (2016). https://doi.org/10.1007/s11356-016-7514-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-016-7514-3