Abstract

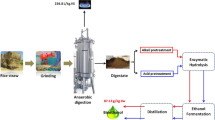

The enhanced H2 production from maize straw had been achieved through the two-stage process of integrating H2 fermentation and microbial electrolysis cells (MECs) in the present work. Several key parameters affecting hydrolysis of maize straw through subcritical H2O were optimized by orthogonal design for saccharification of maize straw followed by H2 production through H2 fermentation. The maximum reducing sugar (RS) content of maize straw reached 469.7 mg/g-TS under the optimal hydrolysis condition with subcritical H2O combining with dilute HCl of 0.3 % at 230 °C. The maximum H2 yield, H2 production rate, and H2 content was 115.1 mL/g-TVS, 2.6 mL/g-TVS/h, and 48.9 % by H2 fermentation, respectively. In addition, the effluent from H2 fermentation was used as feedstock of MECs for additional H2 production. The maximum H2 yield of 1060 mL/g-COD appeared at an applied voltage of 0.8 V, and total COD removal reached about 35 %. The overall H2 yield from maize straw reached 318.5 mL/g-TVS through two-stage processes. The structural characterization of maize straw was also carefully investigated by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), and X-ray diffraction (XRD) spectra.

Similar content being viewed by others

References

Ahmed IN, Sutanto S, Huynh LH, Ismadji S, Ju YH (2013) Subcritical water and dilute acid pretreatments for bioethanol production from Melaleuca leucadendron shedding bark. Biochem Eng J 78:44–52

Alenezi R, Leekea GA, Santosa RCD, Khan AR (2009) Hydrolysis kinetics of sunflower oil under subcritical water conditions. Chem Eng Res Des 87:867–873

Amarasekara AS, Wiredu B (2012) A comparison of dilute aqueous p-toluenesulfonic and sulfuric acid pretreatments and saccharification of corn stover at moderate temperatures and pressures. Bioresour Technol 125:114–118

APHA (1995) Standard methods for the examination of water and wastewater, 19th ed. American Public Health Association, Washington, D.C.

Chen JW, Zhang WG, Zhang HM, Zhang QX, Huang H (2014) Screw extrude steam explosion: a promising pretreatment of corn stover to enhance enzymatic hydrolysis. Bioresour Technol 161:230–235

Chuang YS, Lay CH, Sen B, Chen CC, Wu JH, Lin CS, Lin CY (2011) Biohydrogen and biomethane from water hyacinth (Eichhornia crassipes) fermentation: effects of substrate concentration and incubation temperature. Int J Hydrog Energy 36(21):14195–14203

Cui CW, Shi F, Li YG, Wang SY (2010) Orthogonal analysis for perovskite structure microwave dielectric ceramic thin films fabricated by the RF magnetron-sputtering method. J Mater Sci Mater Electron 21(4):349–354

El-Hendawy AA (2006) Variation in the FTIR spectra of a biomass under impregnation carbonization and oxidation conditions. J Anal Appl Pyrolysis 75:159–166

Esteban MB, Garcia AJ, Ramos P, Márquez MC (2008) Kinetics of amino acid production from hog hair by hydrolysis in sub-critical water. J Supercrit Fluids 46(2):137–141

Fan YT, Zhang YH, Zhang SF, Hou HW, Ren BZ (2006a) Efficient conversion of wheat straw wastes into biohydrogen gas by cow dung compost. Bioresour Technol 97:500–505

Fan YT, Zhang GS, Guo XY, Xing Y, Fan MH (2006b) Bio-hydrogen-production from beer lees biomass by cow dung compost. Biomass Bioenergy 30:493–496

Fang HHP, Li CL, Zhang T (2006) Acidophilic biohydrogen production from rice slurry. Int J Hydrog Energy 31:683–692

Ghose TK (1987) Measurement of cellulose activities. Pure Appl Chem 59:257–268

Goto M, Obuchi R, Hirose T, Sakaki T, Shibata M (2004) Hydrothermal conversion of municipal organic waste into resources. Bioresour Technol 93(3):279–284

Kim TH, Kim JS, Sunwoo C, Lee YY (2003) Pretreatment of corn stover by aqueous ammonia. Bioresour Technol 90(1):39–47

Li XH, Liang DW, Bai YX, Fan YT, Hou HW (2014) Enhanced H2 production from corn stalk by integrating dark fermentation and single-chamber microbial electrolysis cells with double anode arrangement. Int J Hydrog Energy 39:8977–8982

Liang DW, Peng SK, Lu SF, Liu YY, Lan F, Xiang Y (2011) Enhancement of hydrogen production in a single chamber microbial electrolysis cell through anode arrangement optimization. Bioresour Technol 102:10881–10885

Liu A, Park Y, Huang Z, Wang B, Ankumah RO, Biswas PK (2006) Product identification and distribution from hydrothermal conversion of walnut shells. Energy Fuel 20:446–454

Liu ZH, Qin L, Jin MJ, Pang F, Li BZ, Kang Y, Dale BE, Yuan YJ (2013) Evaluation of storage methods for the conversion of corn stover biomass to sugars based on steam explosion pretreatment. Bioresour Technol 132:5–15

Logan BE, Call D, Cheng S, Hamelers HVM, Sleutels THJA, Jere miasse AW, Rozendal RA (2008) Microbial electrolysis cells for high yield hydrogen gas production from organic matter. Environ Sci Technol 42(23):8630–8640

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:420–428

Oh SY, Yoo DI, Shin Y, Kim HC, Kim HY, Chung YS, Park WH, Youk JH (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 40(15):2376–2391

Pan CM, Fan YT, Xing Y, Hou HW, Zhang ML (2008) Statistical optimization of process parameters on biohydrogen-production from glucose by Clostridium sp. Fanp2. Bioresour Technol 99:3146–3157

Rai PK, Singh SP, Asthana RK, Singh S (2004) Biohydrogen production from sugarcane bagasse by integrating dark- and photo-fermentation. Bioresour Technol 152:140–146

Sanchez G, Pilcher L, Roslander C, Modig T, Galbe M, Liden G (2004) Dilute-acid hydrolysis for fermentation of the Bolivian straw material Paja Brava. Bioresour Technol 93:249–256

Sasaki M, Zhen F, Fukushima Y, Adschiri T, Arai K (2000) Dissolution and hydrolysis of cellulose in subcritical and supercritical water. Ind Eng Chem Res 39(8):2883–2890

Segal L, Creely JJ, Martin AE Jr, Conard CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffraction. Text Res J 29:786–794

Shi SL, He WF (2003) Analysis and detection of pulping and papermaking, 1st edn. Chinese Light Industry Press, Beijing, pp 4–39

Song ZX, Wang ZY, Wu LY, Fan YT, Hou HW (2012) Effect of microwave irradiation pretreatment of cow dung compost on bio-hydrogen process from corn stalk by dark fermentation. Int J Hydrog Energy 37:6554–6561

Sun JX, Xu F, Sun XF, Xiao B, Sun RC (2005a) Physico-chemical and thermal characterization of cellulose from barely straw. Polym Degrad Stab 88(3):521–531

Sun XF, Xu F, Sun RC, Fowler P, Baird MS (2005b) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr Res 340(1):97–106

Sun YG, Ma YL, Wang LQ, Wang FZ, Wu QQ, Pan GY (2015) Physicochemical properties of corn stalk after treatment using steam explosion coupled with acid or alkali. Carbohydr Polym 117:486–493

Wang Y, Wan JQ, Ma YW, Huang MZ (2012a) Hydrolysis kinetics characteristic of recycled fiber in subcritical water. Bioresour Technol 105:152–159

Wang YB, Li RJ, Li WW, Fan YT, Hou HW (2012b) Effects of pretreatment of natural bacterial source and raw material on fermentative biohydrogen production. Int J Hydrog Energy 37(1):831–836

Yildiz S, Gumuskaya E (2007) The effects of thermal modification on crystalline structure of cellulose in soft and hard wood. Build Environ 42:62–67

Zhang LH, Xu CB, Champagne P (2010) Energy recovery from secondary pulp/paper-mill sludge and sewage with supercritical water treatment. Bioresour Technol 101(8):2713–2721

Zhao Y, Lu WJ, Wang HT, Li D (2009) Combined supercritical and subcritical process for cellulose hydrolysis to fermentable hexoses. Environ Sci Technol 43(5):1565–1570

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 21171147 and 21373022), the Henan Province Joint Funds of the National Natural Science Foundation of China (U1204522), the Program for Science & Technology Innovation Talents in Universities of Henan Province (13HASTIT033), and the Beijing Nova Program (Z131109000413008).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Angeles Blanco

Yan-Hong Li and Yan-Xia Bai are parallel first authors.

Highlights

>Subcritical H2O hydrolysis is a useful strategy for saccharification of maize straw.

>Dark fermentation combined with MECs is an effective method for improved H2 yield.

>MECs play a key role to convert fermentative effluent into extra H2 and remove COD.

>Max. H2 yield reached 115.1 mL/g-TVS by dark fermentation and 1060 mL/g-COD by MEC.

>Overall H2 yield from maize straw reached 318.5 mL/g-TVS through two-stage processes.

Rights and permissions

About this article

Cite this article

Li, YH., Bai, YX., Pan, CM. et al. Effective conversion of maize straw wastes into bio-hydrogen by two-stage process integrating H2 fermentation and MECs. Environ Sci Pollut Res 22, 18394–18403 (2015). https://doi.org/10.1007/s11356-015-5016-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-015-5016-3