Abstract

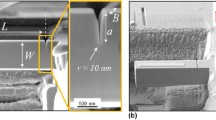

A three-point bend fixture has been designed, fabricated, and utilized to demonstrate the feasibility of performing in-situ J-testing at ambient and elevated temperatures inside a scanning electron microscope (SEM). Using the three-point bend test technique, in-situ SEM J-testing has been performed to measure the crack mouth opening displacement and crack extension as a function of the applied load in order to generate J-R curves for Zircaloy-4 at 25°C and 316°C. Once the J-R curve is determined, an equivalent KJ-resistance (KJ-R) curve is computed on the basis of a relationship between the J-integral (J) and the stress intensity factor (K). The J-R and KJ-R curves of Zircaloy-4 exhibit a rising R-curve behavior, while the elastic K-R curve underestimates the fracture resistance of Zircaloy-4 once substantial crack extension has occurred. For the specimen dimensions considered, the J-R curves generated by in-situ SEM J-tests are not sensitive to the specimen geometry and measure the actual fracture resistance of the material. Furthermore, the onset of crack extension is dictated by the emission of one or more slipbands from the crack tip, and a change in the crack-tip displacement field, followed by void formation along the slipband, and linkage of the voids with the main crack.

Similar content being viewed by others

References

Holt RA (1970) The beta to alpha phase transformation in Zircaloy-4. J Nucl Mater 35:322–334

Woo OT, Tangri K (1979) Transformation characteristics of rapidly heated and overheated Zircaloy-4 oxygen alloys. J Nucl Mater 79:82–94

Woo OT, Tseng D, Tangri K, MacEwen SR (1979) Flow stress and dynamic strain-aging of β-transformed Zircaloy-4. J Nucl Mater 87:135–143

Kreyns PH, Bourgeois WF, White CJ, Carpenter PL, Kammenzind BF, Franklin DG (1996) Embrittlement of reactor core materials in zirconium in the nuclear industry. In: ASTM STP 1295, American Society for Testing and Materials, pp. 758–782

Arias D, Palacios T, Turrillo C (1987) Composition of precipitates present in Zircaloy-2 and 4. J Nucl Mater 148:227–229

Lemaignan C, Motta AT (1994) Zirconium alloys in nuclear applications, nuclear materials, B. R. T. Frost, ed., Vol. 10B, Chapter 7, Materials science and technology, Cahn RW, Haasen P, Kramer EJ (eds), VCH, New York, pp. 1–51

Bertolino G, Meyer G, Ipiña JP (2003) In situ crack growth observation and fracture toughness measurement of hydrogen charged Zircaloy-4. J Nucl Mater 322:57–65

Yawny AA, Ipiña JP (2003) In situ fracture toughness measurement using scanning electron microscopy. J Test Eval 31(5):413–423

Cockeram BV, Chan KS (2009) In situ studies and modeling the fracture of Zircaloy-4. J Nucl Mater 393:387–408

Bertolino G, Meyer G, Ipiña JP (2002) Mechanical properties degradation at room temperatures in ZRY-4 by hydrogen brittleness. Mater Res 5(2):125–129

Raynaud PA, Koss DA, Motta AT, Chan KS (2007) Fracture toughness of hydrided Zircaloy-4 sheet under through-thickness crack growth conditions. Paper ID JAI101183. J ASTM Int 5(1):1–15

Nagy A, Campbell JB, Davidson DL (1984) A high temperature cyclic loading stage for the SEM. Rev Sci Instrum 55:778–782

Rice JR (1968) A path independent integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech 35:379–386

Castrodeza EM, Bastian FL, Yawny A, Ipiña JP (2002) Fracture micromechanisms of fibre-metal laminates: In-situ SEM observations. J Compos Mater 36:387–400

Chan KS, Kim Y-W (1994) Relationships of slip morphology, microcracking, and fracture resistance in a lamellar TiAl-alloy. Metall Mater Trans A 25A:1217–1228

Chan KS, Shih DS (1997) Fatigue and fracture behavior of a fine-grained lamellar TiAl alloy. Metall Mater Trans A 28A:79–90

Chan KS, Shih DS (1998) Fundamental aspects of fatigue fracture in a TiAl sheet alloy. Metall Mater Trans A 29A:73–87

Cockeram BV, Chan KS (2008) In-situ fracture studies and modeling of the toughening mechanism present in wrought LCAC, TZM, and ODS molybdenum flat products. Metall Mater Trans A 39A:2045–2067

ASTM E 1820-99 Standard test method for measurement of fracture toughness, American Society for Testing and Materials, Section 3, Vol. 03.01, pp. 981–1013

Anderson TL (1995) Fracture mechanics, Secondth edn. CRC Press, Boca Raton, FL (Chapter 3, pp. 117-178; Chapter 7; pp. 385–421)

Murakami Y (1987) Stress intensity factors handbook: vol. 1. Pergamon Press, NY, pp 13–17

Kim YJ (2002) Experimental J estimation equations for single-edge-cracked bars in four-point bend: homogeneous and bi-material specimens. Eng Fract Mech 69:793–811

Kim Y-J, Schwalbe K-H (2001) On experimental J estimation equations based on CMOD for SE(B) specimens. J Test Eval 29:67–71

Zerbst U, Heinimann M, Donne CD, Steglich D (2009) Fracture and damage mechanics modeling of thin-walled structure – an overview. Eng Fract Mech 76:5–43

Weitzman RH, Finnie I (1972) Measuring fracture toughness – a simplified test method for plane-strain fracture toughness using controlled crack propagation. J Mater 7:294–299

Hutchinson JW (1968) Singular behavior at the end of a tensile crack in a hardening material. J Mech Phys Solid 16:18–31

Rice JR, Rosengren GF (1968) Plane strain deformation near a crack tip in a power-law hardening material. J Mech Phys Solid 16:1–12

Rice JR, Drugan WJ, Sham TL (1980) Elastic-plastic analysis of growing cracks. In: ASTM STP 700, American Society of Testing and Materials, Philadelphia, PA, pp. 189–221

Chan KS (1990) Crack tip behaviors of stationary and growing cracks in Al-Fe-X alloy: Part II – Crack opening profile. Metall Trans A 21A:81–86

Nakamura T, Parks DM (1988) Conditions for J-dominance in three-dimensional thin cracked plates. In: Rosakis AJ, Ravi-Chandar K, Rajapukse Y (eds) Analytical, numerical and experimental aspects of the three dimensional fracture process, vol. 91. ASME, AMD, New York, NY, pp 227–238

Acknowledgments

The author acknowledges the contributions by Mr. Forrest Campbell in the design of the three-point bend test fixture, Mr. Jose Martinez in performing the in-situ J-testing, and Ms. Loretta Mesa in assisting with the preparation of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chan, K.S. In-Situ SEM J-Testing and Crack-Tip Micromechanics of Zircaloy-4 by Three-Point Bending. Exp Mech 52, 1251–1265 (2012). https://doi.org/10.1007/s11340-011-9587-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-011-9587-8