Abstract

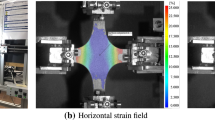

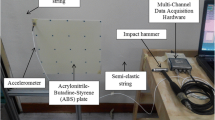

Inverse methods offer a powerful tool for the identification of the elasto-plastic material parameters. One of the advantages with respect to classical material testing is the fact that those inverse methods are able to deal with heterogeneous deformation fields. The basic principle of the inverse method that is presented in this paper, is the comparison between experimentally measured strain fields and those computed by the finite element (FE) method. The unknown material parameters in the FE model are iteratively tuned so as to match the experimentally measured and the numerically computed strain fields as closely as possible. This paper describes the application of an inverse method for the identification of the hardening behavior and the yield locus of DC06 steel, based on a biaxial tensile test on a perforated cruciform specimen. The hardening behavior is described by a Swift type hardening law and the yield locus is modeled with a Hill 1948 yield surface.

Similar content being viewed by others

References

ASTM (1996) ASTM Standard E8M-96. Standard test methods for tension testing of metallic materials [metric]. In: Annual book of ASTM standards, vol. 03.01. ASTM, Philadelphia, pp 76–96.

Boogaard AH (2002) Thermally enhanced forming of aluminium sheet. PhD thesis, Twente University, Twente, The Netherlands.

Mahnken R, Stein E (1996) A unified approach for parameter identification of inelastic material models in the frame of the finite element method. Comput Methods Appl Mech Eng 136:225–258.

Khalfallah A, BelHadjSalah H, Dogui A (2002) Anisotropic parameter identification using inhomogeneous tensile test. Eur J Mech A Solids 21:927–942.

Endelt B, Nielsen KB (2005) General framework for analytical sensitivity analysis for inverse identification of constitutive parameters. In: Proceedings of COMPLAS 2005, 8th international conference on computational plasticity. Barcelona, Spain, 5–7 September.

Ghouati O, Gelin JC (1998) Identification of material parameters directly from metal forming processes. J Mater Process Technol 80–81:560–564.

Ghouati O, Gelin JC (2001) A finite element-based identification method for complex metallic material behaviour. Comput Mater Sci 21:57–68.

Kajberg J, Lindkvist G (2004) Characterization of materials subjected to large strains by inverse modelling based on in-plane displacement fields. Int J Solids Struct 42:3439–3459.

Meuwissen M, Oomens C, Baaijens F, Petterson R, Janssen J (1998) Determination of the elasto-plastic properties of aluminium using a mixed numerical-experimental procedure. J Mater Process Technol 75:204–211.

Grédiac M, Pierron F (2006) Applying the virtual fields methods to the identification of elasto-plastic constitutive parameters. Int J Plast 22:602–627.

Lecompte D, Smits A, Sol H, Vantomme J, Van Hemelrijck D (2007) Mixed numerical-experimental technique for orthotropic parameter identification using biaxial tensile tests on cruciform specimens. Int J Solids Struct 44:1643–1656.

Peters WH, Ranson WF (1982) Digital image techniques on experimental stress analysis. Opt Eng 21(3):427–431.

Chu TC, Ranson WF, Sutton MA, Peters WH (1985) Applications of digital image correlation techniques to experimental mechanics. Exp Mech 25(3):232–244.

Sutton MA, Wolters WJ, Peters WH, Ranson WF, McNeil SR (1983) Determination of displacements using an improved digital correlation method. Image Vis. Comput. 1(3):133–139.

Grédiac M, Toussaint E, Pierron F (2002) Special virtual fields for the direct determination of material parameters with the virtual fields method. 1—Principle and definition. Int J Solids Struct 39:2691–2705.

Grédiac M, Toussaint E, Pierron F (2002) Special virtual fields for the direct determination of material parameters with the virtual fields method. 2—Application to in-plane properties. Int J Solids Struct 39:2707–2730.

Grédiac M, Toussaint E, Pierron F (2003) Special virtual fields for the direct determination of material parameters with the virtual fields method. 3—Application to the bending rigidities of anisotropic plates. Int J Solids Struct 40:2401–2419.

Abaqus Inc. (2006) ABAQUS theory manual, version 6.6. Simulia, Providence.

Ghouati O, Gelin JC (1997) An inverse approach for the identification of complex material behaviours. In: Sol H, Oomens CWJ (eds) Material identification using mixed numerical experimental methods. Kluwer Academic Publishers, Dordrecht, pp 93–102.

Meuwissen M, Oomens C, Baaijens F, Petterson R, Janssen J (1997) Determination of parameters in elasto-plastic models of aluminium. In: Sol H, Oomens CWJ (eds) Material identification using mixed numerical experimental methods. Kluwer Academic Publishers, Dordrecht, pp 71–80.

Gres̆ovnik I (2000) A general purpose computational shell for solving inverse and optimisation problems. PhD thesis, University of Wales.

Kleinermann JP (2000) Identification paramétrique et optimalisation des procédés de mise à forme par problems inverses. Doctoral thesis, University of Liège.

Ponthot JP, Kleinermann JP (2006) A cascade optimization methodology for automatic parameter identification and shape/process optimization in metal forming simulation. Comput Methods Appl Mech Eng 195:5472–5508.

Cooreman S, Lecompte D, Sol H, Vantomme J, Debruyne D (2007) Elasto-plastic material parameter identification by inverse methods: calculation of the sensitivity matrix. Int J Solids Struct 44:4329–4341.

Flores P (2005) Development of experimental equipment and identification procedures for sheet metal constitutive laws. PhD thesis, Université de Liège, Liège, Belgium.

Miller MP, Mc Dowell DL (1996) Modeling large strain multiaxial effects in FCC polycrystals. Int J Plast 12(7):875–902

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cooreman, S., Lecompte, D., Sol, H. et al. Identification of Mechanical Material Behavior Through Inverse Modeling and DIC. Exp Mech 48, 421–433 (2008). https://doi.org/10.1007/s11340-007-9094-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-007-9094-0