Abstract

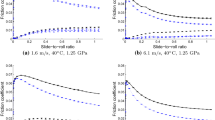

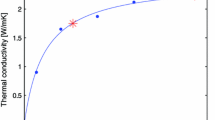

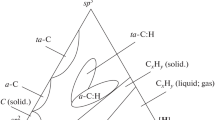

High hardness, high elastic modulus, low friction characteristics, high wear and corrosion resistance, chemical inertness, and thermal stability are factors that make diamond-like carbon (DLC) coatings the subject of many studies. For the same reasons they also seem suitable for use in, amongst others, machine components and cutting tools. While most studies in the literature focus on the influence of coatings on wear and friction in boundary lubrication and pure sliding contacts, few studies can be found concerning rolling and sliding elastohydrodynamic lubrication (EHL) friction, especially in the mixed and full film regime. In this article tests are carried out in a Wedeven Associates Machine tribotester where an uncoated ball and disc pair is compared to the case of coated ball against uncoated disc, coated disc against uncoated ball, and coated disc against coated ball. The tests are conducted at two different temperatures and over a broad range of slide-to-roll ratios and entrainment speeds. The results are presented as friction maps as introduced in previous work (Björling et al. in J Eng Tribol 225(7):671, 2011). Furthermore a numerical simulation model is developed to investigate if there is a possibility that the hard, thin DLC coating is affecting the friction coefficient in an EHL contact due to thermal effects caused by the different thermal properties of the coating compared to the substrate. The experimental results show a reduction in friction coefficient in the full film regime when DLC-coated surfaces are used. The biggest reduction is found when both surfaces are coated, followed by the case when either ball or disc is coated. The thermal simulation model shows a substantial increase of the lubricant film temperature compared to uncoated surfaces when both surfaces are coated with DLC. The reduction in friction coefficient when coating either only the ball or the disc are almost the same, lower than when coating both the surfaces but still higher than the uncoated case. The findings above indicate that it is reasonable to conclude that thermal effects are a likely cause for the decrease in coefficient of friction when operating under full film conditions, and in the mixed lubrication regime when DLC-coated surfaces are used.

Similar content being viewed by others

References

Ronkainen, H., Varjus, D., Holmberg, K.: Friction and wear properties in dry, water- and oil-lubricated DLC against alumina and DLC against steel contacts. Wear 222(2), 120 (1998)

Zhou, Z., Li, K., Bello, I., Lee, C., Lee, S.: Study of tribological performance of ECR–CVD diamond-like carbon coatings on steel substrates. Part 2. The analysis of wear mechanism. Wear 258(10), 1589 (2005)

Podgornik, B., Jacobson, S., Hogmark, S.: DLC coating of boundary lubricated components—advantages of coating one of the contact surfaces rather than both or none. Tribol. Int. 36(11), 843 (2003)

Podgornik, B., Jacobson, S., Hogmark, S.: Influence of EP additive concentration on the tribological behaviour of DLC-coated steel surfaces. Surf. Coat. Technol. 191(2–3), 357 (2005)

Podgornik, B., Hren, D., Vižintin, J.: Combination of DLC coatings and EP additives for improved tribological behaviour of boundary lubricated surfaces. Wear 261(1), 32 (2006)

Mistry, K., Morina, A., Neville, A.: Tribo-chemistry of lubricated DLC coatings for engineering components under extreme-pressure contact conditions. Tribol. Lubr. Technol. 66(5), 16 (2010)

de Barros’Bochet, M., Martin, J., Le-Mogne, T., Vacher, B.: Lubrication of carbon coatings with MoS2 single sheet formed by MoDTC and ZDDP lubricants. Lubr. Sci. 18(3), 141 (2006)

de Barros’Bochet, M., Martin, J., Le-Mogne, T., Vacher, B.: Boundary lubrication mechanisms of carbon coatings by MoDTC and ZDDP additives. Tribol. Int. 38(3), 257 (2005)

Miyake, S., Saito, T., Yasuda, Y., Okamato, Y., Kano, M.: Improvement of boundary lubrication properties of diamond-like carbon (DLC) films due to metal addition. Tribol. Int. 37(9), 751 (2004)

Haque, T., Morina, A., Neville, A., Kapadia, R., Arrowsmith, S.: Effect of oil additives on the durability of hydrogenated DLC coating under boundary lubrication conditions. Wear 266(1–2), 147 (2009)

Kalin, M., Roman, E., Ožbolt, L., Vižintin, J.: Metal-doped (Ti, WC) diamond-like-carbon coatings: reactions with extreme-pressure oil additives under tribological and static conditions. Thin Solid Films 518(15), 4336 (2010)

Topolovec-Miklozic, K., Lockwood, F., Spikes, H.: Behaviour of boundary lubricating additives on DLC coatings. Wear 265(11–12), 1893 (2008)

Yoshida, K., Horiuchi, T., Kano, M., Kumagai, M.: Effect of a tribochemical reacted film on friction and wear properties of DLC coatings. Plasma Process. Polym. 6(1), S96 (2009)

Renodeau, H., Papke, B., Pozebanchukz, M., Parthasarathy, P.: Tribological properties of diamond-like carbon coatings in lubricated automotive applications. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 223(3), 405 (2009)

Kalin, M., Vižintin, J.: Differences in the tribological mechanisms when using non-doped, metal-doped (Ti, WC), and non-metal-doped (Si) diamond-like carbon against steel under boundary lubrication, with and without oil additives. Thin Solid Films 515(4), 2734 (2006)

Bobzin, K., Bagcivan, N., Goebbels, N., Yilmaz, K., Hoehn, B.R., Michaelis, K., Hochmann, M.: Lubricated PVD CrAlN and WC/C coatings for automotive applications. Surf. Coat. Technol. 204(6-7), 1097 (2009)

Xu, H.: Development of a generalized mechanical efficiency prediction methodology for gear pairs. PhD thesis, Graduate School of The Ohio State University (2005)

Evans, R., Cogdell, J., Richter, G.: Traction of lubricated rolling contacts between thin-film coatings and steel. Tribol. Trans. 52(1), 106 (2009)

Choo, J., Glovnea, R., Forrest, A., Spikes, H.: A low friction bearing based on liquid slip at the wall. J. Tribol. 129(3), 611 (2007)

Björling, M., Larsson, R., Marklund, P., Kassfeldt, E.: Elastohydrodynamic lubrication friction mapping—the influence of lubricant, roughness, speed, and slide-to-roll ratio. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 225(7), 671 (2011)

Larsson, R., Larsson, P., Eriksson, E., Sjoberg, M., Hoglund, E.: Lubricant properties for input to hydrodynamic and elastohydrodynamic lubrication analyses. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 214(1), 17 (2000)

Habchi, W., Eyheramendy, D., Bair, S., Vergne, P., Morales-Espejel, G.: Thermal elastohydrodynamic lubrication of point contacts using a newtonian/generalized newtonian lubricant. Tribol. lett. 30(1), 41 (2008)

Kim, J., Yang, H.S., Jun, Y., Kim, K.: Interfacial effect on thermal conductivity of diamond-like carbon films. J. Mech. Sci. Technol. 24(7), 1511 (2010)

Wojciechowski, K., Zybala, R., Mania, R.: Application of DLC layers in 3-omega thermal conductivity method. J. Achiev. Mater. Manuf. Eng. 37(2), 512 (2009)

Hakovirta, M., Vuorinen, J., He, X., Nastasi, M., Schwarz, R.: Heat capacity of hydrogenated diamond-like carbon films. Appl. Phys. Lett. 77(15), 2340 (2000)

Oka, Y., Kirinuki, M., Suzuki, T., Yatsuzuka, M., Yatsui, K.: Effect of ion beam implantation on density of DLC prepared by plasma-based ion implantation and deposition. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 242(1–2), 335 (2006)

Hamrock, B., Schmid, S., Jacobson, B.: Fundamentals of Fluid Film Lubrication, 2nd edn. Marcel Dekker Inc., New York (2004)

Hsu, C.H., Lee, R.T.: An efficient algorithm for thermal elastohydrodynamic lubrication under rolling/sliding line contacts. J. Tribol. 116(4), 762 (1994)

Acknowledgments

The authors gratefully acknowledge industrial partners Volvo Construction Equipment, Scania and Vicura AB for support, Ion bond for providing the coatings, Statoil lubricants for providing the test lubricant, and Swedish Foundation for Strategic Research (ProViking) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Björling, M., Isaksson, P., Marklund, P. et al. The Influence of DLC Coating on EHL Friction Coefficient. Tribol Lett 47, 285–294 (2012). https://doi.org/10.1007/s11249-012-9987-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-9987-7