Abstract

Hydroformylation of 1-octene with the heterodinuclear (Fe, Co) complex [CoH(dchpf)(CO)2] (1) was investigated (dchpf = 1,1′-bis(dicyclohexylphosphino)ferrocene). In agreement with this cobalt complex possessing a preformed hydride as well as carbonyl ligands, the pre-activated catalyst does not require any induction process or activation treatment to become reactive in hydroformylation. The catalyst activity and (chemo-)selectivity proved to be strongly dependent on the applied reaction conditions. Higher syngas pressures suppress alkene isomerization and favor the hydroformylation reaction. The overall regio-selectivity remains very similar within the investigated reaction space, with the C1-selectivity varying between 48 and 69 %. An increase of the reaction temperature at 40 bars results in a progressive decrease of the C1-selectivity and an increase in the C2- and C3-selectivity due to a higher isomerization activity at elevated temperatures. Furthermore, at high temperatures (170 °C) and low syngas pressures (10–20 bar) the main oxygenated products are the alcohols, resulting from reduction of the aldehydes. However, when using a combination of higher syngas pressures and intermediate temperatures, the reaction could be optimized towards the formation of aldehydes. At 140 °C and 40 bars syngas pressure quite selective hydroformylation of 1-octene could be achieved, yielding 57 % aldehydes and only 1.3 % over-reduction to the corresponding alcohol.

Similar content being viewed by others

1 Introduction

In a recent report [1] we have described the mechanism of hydrogen formation activity of a dicarbonylhydridocobalt compound [Co(dippf)(CO)2H] which is chelated by 1,1′-bis(diisopropylphosphino)ferrocene (dippf) [2, 3]. Cobalt coordination compounds in general have become popular for H2 conversion research [4–8], alkene hydrogenation [9–13], controlled radical polymerisation [14–19] and carbene- and nitrene-transfer reactions [20–24]. Cobalt-mediated hydroformylation is well-known and has been continuously reviewed [25–27]. While Beller, Cole-Hamilton and others have reported various kinds of modifications [28–31] of the original catalytic system, there have also been computational approaches from the groups of Beller and Pringle to the Co complex-catalyzed hydroformylation [32, 33]. However, not many studies describe the use of well-defined complexes with bidentate chelating P-donors [34], and none (to the best of our knowledge) report the use of isolated carbonyl-hydrido-cobalt compounds.

Hydroformylation [35–39] is arguably one of the most important homogeneously catalyzed reactions: it is applied commercially on a multimillion ton per year scale, but also studied in great detail at the fundamental level for rhodium-based catalysts [40, 41]. Fewer reports have been disclosed on the use of well-defined cobalt catalysts, despite the lower price and much higher abundancy of cobalt as compared to rhodium. This is in part a result of the lower selectivity of cobalt catalysts, typically giving rise to lower linear (C1)/branched (C3) selectivities, alkene isomerization, and over-reduction of the aldehydes to the corresponding alcohols [42]. However, well-defined cobalt complexes with strongly chelating bidentate P-donor ligands imposing a fixed and rigid coordination geometry may well lead to improved activity and higher selectivities. As such, the development of stable and more selective cobalt catalysts for hydroformylation reactions is desirable, both from a standpoint of cost reduction and in view of material scarcity. In this perspective, the new heterodinuclear complex [CoH(dchpf)(CO)2] = 1 has become of particular interest to us, as it promised to be a well-defined molecular framework containing a stable, rigidly coordinating bidentate P-donor ligand (dchpf) = 1,1′-bis(dicyclohexylphosphino)ferrocene. Furthermore, since the complex contains a pre-formed hydride ligand as well as carbonyl moieties, the complex can be considered as the active form of a hydroformylation catalyst and should therefore not require any induction or catalyst activation pre-treatment. In this paper we report the study of complex 1 in the hydroformylation of 1-octene, in a sufficiently large reaction space (temperature, syngas pressure) to allow the mapping of the activity and chemo/regioselectivity of the catalyst.

2 Results and Discussion

Compound 1 was obtained in a similar fashion as the related complex [CoH(dippf)(CO)2] [1] by reaction of in situ generated CoH(CO)4 with the diphosphinoferrocene, here dchpf, in quantitative yield. Analytical data and spectroscopy (1H- and 31P-NMR, IR) confirm the composition (see Experimental Section in the Supporting Information), and a single crystal X-ray diffraction analysis provides a view of the molecular structure (Fig. 1). The low crystal quality did not allow us to locate the hydride ligand which is, however, clearly observed in the 1H NMR spectrum at −12.26 ppm (t), signifying a pronounced hydridic character. The hydride is assumed to be in an axial position of an approximately trigonal–bipyramidal (tbp) arrangement, trans to C1 of one carbonyl ligand. The other carbonyl and the two phosphorus donors occupy the quasi-equatorial positions. However, it should be realized that the structure lies between the tbp and sqp (square-pyramidal) alternatives. The ferrocene part adopts a synperiplanar eclipsed conformation. Any small differences between the structures of 1 and its dippf analogue [1] can be attributed to the increased steric congestion in the new system 1 which also prevents the formation of IR-detectable dimers. It may be added that 1 can be oxidized reversibly in dichloromethane at −0.57 V versus Fc+/o, at a slightly lower potential than the less electron-rich dippf analogue (0.43 V) [1]. According to the results [1] for [CoH(dippf)(CO)2]°/+/2+ the first reversible oxidation is attributed to the cobalt center. A second, irreversible oxidation at +0.11 V anodic peak potential is identified with the ferrocene iron oxidation [1].

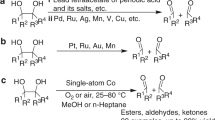

The complex [CoH(dchpf)(CO)2] (1) has been investigated in the hydroformylation reaction using 1-octene as substrate under various reaction conditions. The hydroformylation reactions have been performed in an AMTEC SPR 16 parallel autoclave system for which the temperature and the pressure could be independently programmed for each reactor. The gas-uptake curve of every individual reactor has been recorded. The catalyst (1) has been tested in the temperature range between 100 and 170 °C and between 10 and 40 bars of syngas pressure. Besides the desired aldehydes, the typical cobalt-hydroformylation products formed by alkene isomerization, alkene hydrogenation, and aldehyde hydrogenation to the corresponding alcohols were detected in the reaction mixtures (see Scheme 1). The results of the hydroformylation reactions are presented in Table 1.

From Table 1 it is clear that the catalyst activity and (chemo-)selectivity depend strongly on the applied reaction conditions. The conversion of 1-octene appears to be mainly dependent on the reaction temperature. At 10 bar syngas pressures, the 1-octene is mainly converted to internal octene isomers. At 10 bars syngas pressure and 170 °C, the total amount of oxygenates is 21.2 % of which the alcohols are the major oxygenated reaction products.

Increasing the syngas pressure in a stepwise manner from 10 to 40 bars led to a gradual increase in the formation of oxygenated products (see Fig. 2). At 140 °C and 40 bars syngas pressure the total amount of aldehydes formed is 44.3 %, with only 1.3 % over-reduction to the alcohols. Further increasing the temperature to 170 °C yields 52.1 % aldehydes, but concomitantly the production of alcohols also increases (13.4 %). Furthermore, it is interesting to note that at 120 °C, the conversion decreases with increasing syngas pressure, while the overall yield of hydroformylation products increases. These observations are similar to the general trends observed in rhodium-catalyzed hydroformylation, where higher syngas pressures suppress alkene isomerization and favor the hydroformylation reaction [43].

The C1- and the C2-selectivity data presented in Table 1 are plotted in Figs. 3 and 4. These plots show that the overall regio-selectivity remains very similar within the investigated reaction space. The C1-selectivity, determined by the levels of nonanal and nonanol present in the reaction mixture, varies between 48.5 and 69.4 %. From Fig. 3 can be concluded that an increase of the reaction temperature at 40 bars results in a progressive decrease of the C1-selecitvity and an increase in the C2- and C3-selectivity (see Fig. 4 and supporting information). This is ascribed to a higher isomerization activity of the catalyst at elevated temperature; an effect that has also been observed in rhodium-catalyzed hydroformylation [43]. In addition, the amount of octene hydrogenation producing octane is limited (between 1.3 and 10.3 %), which is comparable to the best cobalt mono-phosphine systems [42].

Progression of the C1-selectivity as a function of syngas pressure and temperature determined from the 16 hydroformylation reactions described in Table 1

Progression of the C2-selectivity as a function of syngas pressure and temperature determined from the 16 hydroformylation reactions described in Table 1

Typically, in both rhodium and cobalt hydroformylation catalysis, the pre-catalyst requires an activation step to form the catalytically active [MH(CO)4] species which can enter into the catalytic cycle. This activation process normally requires anywhere from 30 min to a couple of hours [44]. The cobalt complex [CoH(dchpf)(CO)2] (1), possessing both a preformed hydride and carbonyl ligands, can be regarded as the pre-activated catalyst and should thus not require any induction time before being active in the hydroformylation reaction. This is indeed confirmed by the recorded gas-uptake curves which all display a typical exponential progress (see SI for recorded gas-uptake curves). No sigmoidal curves were observed in any of the recorded gas-uptake curves.

Converting the conversion plots (mol vs. time) to the corresponding rate versus [substrate concentration] plots provided more detailed information about the hydroformylation process mediated by complex 1. The reactions at 140 °C have been used for the reaction progress kinetic analysis, because these reactions provide sufficient conversion levels and a limited over-reduction to the corresponding alcohols. The plots are provided in Fig. 5. From the curves it is clear that there is no induction period, as this would lead to an increase in the rate with the progression of the reaction [45]. Instead a downward curvature is observed which can be attributed to the alkene isomerization activity, gradually converting the more reactive 1-octene substrate into the less reactive internal octenes.

3 Conclusions

In conclusion, the new heterodinuclear complex [CoH(dchpf)(CO)2] with a (cyclohexyl-) shielded metal reaction site proves to be an effective hydroformylation catalyst even under remarkably low syngas pressures. The catalyst does not display any induction period confirming that the catalyst is already in its activated form. Within this study, the selective hydroformylation of 1-octene yielding 56.7 % aldehydes and only 1.3 % over-reduction to the corresponding alcohol could be achieved at 140 °C and 40 bars syngas pressure. In addition, the alkene hydrogenation was found to be low using cobalt complex 1 as the catalyst. Further conceivable in situ experiments under controlled conditions can be expected to shed more light on the detailed hydroformylation mechanism involving this apparently unique kind of complex.

References

Krafft MJ, Bubrin M, Paretzki A, Lissner F, Fiedler J, Záliš S, Kaim W (2013) Angew Chem Int Ed 52:6781–6784

Driver MS, Hartwig JF (1996) J Am Chem Soc 118:7217–7218

Young DJ, Chien SW, Hor TSA (2012) Dalton Trans 41:12655–12665

Artero V, Chavarot-Kerlidou M, Fontecave M (2011) Angew Chem Int Ed 50:7238–7266

Andreiadis ES, Jacques P-A, Tran PD, Leyris A, Chavarot-Kerlidou M, Jousselme B, Matheron M, Pécaut J, Palacin S, Fontecave M, Artero V (2013) Nature Chem 5:48–53

Valdez CN, Dempsey JL, Brunschwig BS, Winkler JR, Gray HB (2012) PNAS 109:15589

Reece SY, Hamel JA, Sung K, Jarvi TD, Esswein AJ, Pijpers JJH, Nocera DG (2011) Science 334:645–648

Ciancanelli R, Noll BC, DuBois DL, DuBois MR (2002) J Am Chem Soc 124:2984–2992

Yu RP, Darmon JM, Milsmann C, Margulieux GW, Stieber SCE, DeBeer S, Chirik PJ (2013) J Am Chem Soc 135:13168–13184

Monfette S, Turner ZR, Semproni SP, Chirik PJ (2012) J Am Chem Soc 134:4561–4564

Knijnenburg Q, Horton AD, van der Heijden H, Kooistra TM, Hetterscheid DGH, Smits JMM, de Bruin B, Budzelaar PHM, Gal AW (2005) J Mol Catal A 232:151–159

Knijnenburg Q, Horton AD, van der Heijden H, Gal AW, Budzelaar PHM (2003) Int Pat Appl WO2003042131–A120030522

Korstanje TJ, van der Vlugt JI, Elsevier CJ, de Bruin B (2015) Science 350(6258):298–302

Debuigne A, Poli R, Jérôme C, Jérôme R, Detrembleur C (2009) Progr Pol Sci 34:211–239

Gridnev A (2000) J Polym Sci A 38:1753–1766

Wayland BB, Poszmik G, Mukerjee SL, Fryd M (1994) J Am Chem Soc 116:7943–7944

Peng C-H, Scricco J, Li S, Fryd M, Wayland BB (2008) Macromolecules 41:2368–2373

Li S, de Bruin B, Peng C-H, Fryd M, Wayland BB (2008) J Am Chem Soc 130:13373–13381

de Bruin B, Dzik WI, Li S, Wayland BB (2009) Chem Eur J 15:4312–4320

Dzik WI, Xu X, Zhang XP, Reek JNH, de Bruin B (2010) J Am Chem Soc 132:10891–10902

Lyaskovskyy V, Olivos Suárez AI, Lu H, Jiang H, Zhang XP, de Bruin B (2011) J Am Chem Soc 133:12264–12273

Paul ND, Chirila A, Lu H, Zhang XP, de Bruin B (2013) Chem Eur J 19:12953–12958

Paul ND, Mandal S, Otte M, Cui X, Zhang XP, de Bruin B (2014) J Am Chem Soc 136:1090–1096

Goswami M, Lyaskovskyy V, Domingos SR, Buma WJ, Woutersen S, Troeppner O, Ivanović-Burmazović I, Lu H, Cui X, Zhang XP, Reijerse EJ, DeBeer S, van Schooneveld MM, Pfaff FF, Ray K, de Bruin B (2015) J Am Chem Soc 137:5468–5479

van Leeuwen PWNM (2014) Science of synthesis: C-1 building blocks in organic synthesis, vol 1. Georg Thieme Verlag, Stuttgart

van Leeuwen PWNM, Chadwick JC (2011) Homogeneous catalysts: activity—stability—deactivation. Wiley, Weinheim

Beller M (ed) (2006) Catalytic carbonylation reactions. Springer, Heidelberg

Pospech J, Fleischer I, Franke R, Buchholz S, Beller M (2013) Angew Chem Int Ed 52:2852–2872

Hebrard F, Kalck P (2009) Chem Rev 109:4272–4282

Polas A, Wilton-Ely JDET, Slawin AMZ, Foster DF, Steynberg PJ, Green MJ, Cole-Hamilton DJ (2003) Dalton Trans 24:4669–4677

Beller M, Krauter JGE (1999) J Mol Catal A 143:31–39

Huo C, Beller M, Jiao H (2012) In: Wiest O, Wu Y (eds) Computational organometallic chemistry. Springer, Berlin, p 219

Rush LE, Pringle PG, Harvey JN (2014) Angew Chem Int Ed 53:8672–8676

Cornely W, Fell B (1982) J Mol Catal 16:89–94

Roelen O (1951) Angew Chem 63:482–483

Cornils B, Herrmann WA, Rasch M (1994) Angew Chem Int Ed 33:2144–2163

Breslow DS, Heck RF (1960) Chem. Ind. (Lond.) 467

Heck RF, Breslow DS (1961) J Am Chem Soc 83:4023–4027

Slaugh LH, Mullineaux RD (1968) J Organomet Chem 13:469–477

Franke R, Selent D, Börner A (2012) Chem Rev 112:5675–5732

Frey GD (2014) J Organomet Chem 754:5–7

Bungu PN, Otto S (2011) Dalton Trans 40:9238–9249

van Leeuwen PWNM (2000) Chapter 3. In: van Leeuwen PWNM, Claver C (eds) Rhodium catalyzed hydroformylation. Kluwer Academic Publishers, Dordrecht

Claver C, van Leeuwen PWNM (2000) Chapter 5. In: van Leeuwen PWNM, Claver C (eds) Rhodium catalyzed hydroformylation. Kluwer Academic Publishers, Dordrecht

Mathew SP, Gunathilagan S, Roberts SM, Blackmond DG (2005) Org Lett 22:4847–4850

Acknowledgments

The work was financially supported by The Netherlands Organization for Scientific Research (NWO-CW VICI Grant No. 016.122.613, BdB), the Research Priority Area Sustainable Chemistry of the University of Amsterdam (BdB), InCatT B.V. (AMK), the University of Stuttgart (WK), the State of Baden-Württemberg (WK), the DFG (WK) and COST program (CM1202) of the EU.

Author information

Authors and Affiliations

Corresponding authors

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kluwer, A.M., Krafft, M.J., Hartenbach, I. et al. Hydroformylation of 1-Octene Mediated by the Cobalt Complex [CoH(dchpf)(CO)2]. Top Catal 59, 1787–1792 (2016). https://doi.org/10.1007/s11244-016-0699-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-016-0699-3