Abstract

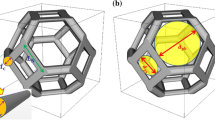

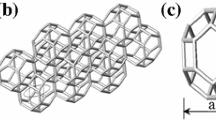

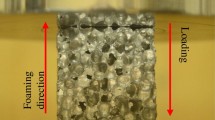

Various ideal periodic isotropic structures of foams (tetrakaidecahedron) with constant ligament cross section are studied. Different strut shapes namely circular, square, diamond, hexagon, star, and their various orientations are modeled using CAD. We performed direct numerical simulations at pore scale, solving Navier–Stokes equation in the fluid space to obtain various flow properties namely permeability and inertia coefficient for all shapes in the porosity range, \(0.60<\varepsilon <0.95\) for wide range of Reynolds numbers, \(10^{-6}<Re<3000\). We proposed an analytical model to obtain pressure drop in metallic foams in order to correlate the resulting macroscopic pressure and velocity gradients with the Ergun-like approach. The analytical results are fully compared with the available numerical data, and an excellent agreement is observed.

Similar content being viewed by others

Abbreviations

- \(\Delta P\) :

-

Pressure drop (\(\hbox {Pa}\))

- \(\Delta x\) :

-

Length of fluid medium (\(\hbox {m}\))

- \(K\) :

-

Forchheimer permeability (\(\hbox {m}^{2}\))

- \(K^{\prime }\) :

-

Darcian permeability (\(\hbox {m}^{2}\)) (Eq. 7)

- \(\beta \) :

-

Inertia coefficient (polynomial curve) (\(\hbox {m}^{-1}\))

- \(\beta ^{\prime }\) :

-

Forchheimer inertia coefficient (\(\hbox {m}^{-1}\)) (Eq. 13)

- \(V_\mathrm{s}\) :

-

Solid volume of foam (\(\hbox {m}^{3}\))

- \(V_\mathrm{T}\) :

-

Volume of octahedron (\(\hbox {m}^{3}\))

- \(V\) :

-

Superficial fluid velocity (\(\hbox {m}\,\hbox {s}^{-1}\))

- \(A\) :

-

Ergun parameter (dimensionless)

- \(B\) :

-

Ergun parameter (dimensionless)

- \(f\) :

-

Universal inertial coefficient (dimensionless)

- \(Re_\mathrm{c}\) :

-

Critical Reynolds number (dimensionless)

- \(D_\mathrm{p}\) :

-

Particle diameter (\(\mathrm{m}\))

- \(Re\) :

-

Reynolds number (dimensionless)

- \(a_\mathrm{c}\) :

-

Specific surface area (\(\mathrm{m}^{-1}\))

- \(d_\mathrm{p}\) :

-

Pore diameter (\(\hbox {m}\))

- \(d_\mathrm{cell} \) :

-

Cell diameter (\(\hbox {m}\))

- \(\nabla P\) :

-

Pressure gradient (\(\mathrm{Pa\,m^{-1}}\))

- \(\nabla \langle P \rangle \) :

-

Average Pressure gradient (\(\mathrm{Pa}\, \mathrm{m}^{-1}\))

- \(\langle V\rangle \) :

-

average velocity (\(\hbox {m}\,\hbox {s}^{-1}\))

- \(P\) :

-

Fluid force (\(\mathrm{N}\))

- \(S\) :

-

Solid-fluid interface area (\(\hbox {m}^{2}\))

- \(d_\mathrm{p}^\mathrm{eq}\) :

-

Equivalent sphere diameter (\(\hbox {m}\))

- \(d_\mathrm{s}\) :

-

Strut diameter (\(\hbox {m}\))

- \(A_\mathrm{side}\) :

-

Side length of strut shape (\(\hbox {m}\))

- \(\varepsilon \) :

-

Porosity, dimensionless

- \(\mu \) :

-

Fluid viscosity (\(\hbox {kg m}^{-1}\,\hbox {s}^{-1}\))

- \(\rho \) :

-

Fluid density (\(\hbox {kg m}^{-3}\))

- \(\varepsilon _\mathrm{sur} \) :

-

Surface Porosity (dimensionless)

References

Alder, P.M., Malevich, A.E., Mityushev, V.V.: Nonlinear correction to Darcy’s law for channels with wavy wall. Acta Mech. 224, 1823–1848 (2013)

Avenall, R.J.: Use of metallic foams for heat transfer enhancement in the cooling jacket of a rocket propulsion element. Master’s thesis, University of Florida (2004)

Beavers, G.S., Sparrow, E.M.: Non-Darcy flow through fibrous porous media. J. Appl. Mech. 36(4), 711–714 (1969)

Bhattacharya, A., Calmidi, V.V., Mahajan, R.L.: Thermophysical properties of high porosity metal foams. Int. J. Heat Mass Transf. 45(5), 1017–1031 (2002)

Bonnet, J.P., Topin, F., Tadrist, L.: Flow laws in metal foams: compressibility and pore size effects. Transp. Porous Media 73(2), 233–254 (2008)

Boomsma, K., Poulikakos, D.: The effects of compression and pore size variations on the liquid flow characteristics in metal foams. J. Fluids Eng. 124(1), 263–272 (2002)

Buciuman, F.C., Kraushaar-Czarnetzki, B.: Ceramic foam monoliths as catalyst carriers. 1. Adjustment and description of the morphology. J. Ind. Eng. Chem. Res. 42, 1863–1869 (2003)

Chauveteau, G.: Essai sur la loi de Darcy. PhD thesis, University of Toulouse (1965)

Dairon, J., Gaillard, Y.: Casting parts with CTIF foams. MetFoam Conference, Brastislava (2009)

De Jaeger, P., T’Joen, C., Huisseune, H., Ameel, B., De Paepe, M.: An experimentally validated and parameterized periodic unit-cell reconstruction of open-cell foams. J. Appl. Phy. 109(10), 103519 (2011)

Dietrich, B., Schabel, W., Kind, M., Martin, H.: Pressure drop measurements of ceramic sponges—determining the hydraulic diameter. Chem. Eng. Sci. 64(16), 3633–3640 (2009)

Du Plessis, P., Montillet, A., Comiti, J., Legrand, J.: Pressure drop prediction for flow through high porosity metal foams. Chem. Eng. Sci. 49(21), 3545–3553 (1994)

Edouard, D., Lacroix, M., Huu, C.P., Luck, F.: Pressure drop modeling on solid foam: state-of-the-art correlation. Chem. Eng. J. 144(2), 299–311 (2008)

Ergun, S., Orning, A.A.: Fluid flow through randomly packed columns and fluidized beds. Ind. Eng. Chem. Res. 41, 1179–1184 (1949)

Firdaous, M., Guermond, J.L., Le Quere, P.: Nonlinear corrections to Darcy’s law at low Reynolds numbers. J. Fluid Mech. 343, 331–350 (1997)

Fourar, M., Radilla, G., Lenormand, R., Moyne, C.: On the non-linear behavior of a laminar single-phase flow through two and three-dimensional porous media. Adv. Water Resour. 27(6), 669–677 (2004)

Giani, L., Groppi, G., Tronconi, E.: Mass-transfer characterization of metallic foams as supports for structured catalysts. Ind. Eng. Chem. Res. 44(14), 4993–5002 (2005)

Gibson, L.J., Ashby, M.F.: Cellular Solids: Structure and Properties, 2nd edn. Cambridge University Press, Cambridge (1997)

Inayat, A., Freund, H., Zeiser, T., Schwieger, W.: Determining the specific surface area of ceramic foams: the tetrakaidecahedra model revisited. Chem. Eng. Sci. 66(6), 1179–1188 (2011)

Incera Garrido, G., Patcas, F.C., Lang, S., Kraushaar-Czarnetzki, B.: Mass transfer and pressure drop in ceramic foams: a description of different pore sizes and porosities. Chem. Eng. Sci. 63(21), 5202–5217 (2008)

Jung, A., Natter, H., Diebels, S., Lach, E., Hempelmann, R.: Nano-Nickel coated aluminum foam for enhanced impact energy absorption. Adv. Eng. Mat. 13(1–2), 23–28 (2011)

Kanaun, S., Tkachenko, O.: Effective conductive properties of open-cell foams. Int. J. Eng. Sci. 46, 551–571 (2008)

Kim, S.Y., Paek, J.W., Kang, B.H.: Flow and heat transfer correlations for porous fin in plate-fin heat exchanger. J. Heat Transf. 122(3), 572–578 (2000)

Lacroix, M., Nguyen, P., Schweich, D., Huu, C., Savin-Poncet, S., Edouard, D.: Pressure drop measurements and modeling on SiC foams. Chem. Eng. Sci. 62(12), 3259–3267 (2007)

Lafdi, K., Mesalhy, O., Shaikh, S.: Experimental study on the influence of foam porosity and pore size on the melting of phase change materials. J. Appl. Phy. 102, 083549 (2007)

Langlois, S., Coeuret, F.: Flow-through and flow-by porous electrodes of nickel foam. I. Material characterization. J. Appl. Electrochem. 19(1), 43–50 (1989)

Losito, O.: An analytical characterization of metal foams for shielding applications. PIERS Online 4, 805–810 (2008)

Lu, T.J., Stone, H.A., Ashby, M.F.: Heat transfer in open-cell metal foams. Acta Mater. 46(10), 3619–3635 (1998)

Madani, B., Topin, F., Tadrist, L., Rigollet, F.: Flow laws in metallic foams: experimental determination of inertial and viscous contribution. J. Porous Media 10(1), 51–70 (2006)

Mei, C.C., Auriault, J.L.: The effect of weak inertia on flow through a porous medium. J. Fluid Mech. 222, 647–663 (1991)

Moreira, E.A., Innocentini, M.D.M., Coury, J.R.: Permeability of ceramic foams to compressible and incompressible flow. J. Eur. Ceram. Soc. 24(10–11), 3209–3218 (2004)

Richardson, J.T., Peng, Y., Remue, D.: Properties of ceramic foam catalyst supports: pressure drop. Appl. Catal. A 204(1), 19–32 (2000)

Vicente, J., Topin, F., Daurelle, J.V.: Open celled material structural properties measurement: from morphology to transport properties. Mater. Trans. 47(9), 2195–2202 (2006)

Whitaker, S.: The Method of Averaging, vol. 13. Kluwer Academic Publisher, Dordrecht (1999)

Wodie, J.C., Levy, T.: Correction non linéaire de la loi de Darcy. Comptes rendus de l’Académie des sciences 312(2), 157–161 (1991)

Acknowledgments

The authors express their gratitude to ANR (Agence Nationale de la Recherche) for financial support in the framework of FOAM project and all project partners for their assistance.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

Specific surface area of a square strut shape is given as

where \(\alpha _\mathrm{s} =\frac{A_\mathrm{s} }{L}\) and \(\beta =\frac{L_\mathrm{s} }{L}\).

Specific surface area of a rotated square strut shape is given as

where \(\alpha _\mathrm{rs} =\frac{A_\mathrm{rs} }{L}\) and \(\beta =\frac{L_\mathrm{s} }{L}\).

Specific surface area of a diamond strut shape is given as

where \(\alpha _\mathrm{det} =\frac{A_\mathrm{rs} }{L}\) and \(\beta =\frac{L_\mathrm{s} }{L}\).

Specific surface area of a hexagon strut shape is given as

where \(\alpha _\mathrm{h} =\frac{A_\mathrm{h} }{L}\) and \(\beta =\frac{L_\mathrm{s} }{L}\).

Specific surface area of a star strut shape is given as

where \(\alpha _\mathrm{st} =\frac{A_\mathrm{st} }{L}\) and \(\beta =\frac{L_\mathrm{s} }{L}\).

Appendix 2

For a square strut shape, \(R_\mathrm{eq} =A_\mathrm{s} /\sqrt{\pi }\)

For a rotated square strut shape, \(R_\mathrm{eq} =A_\mathrm{rs} /\sqrt{\pi }\)

For a diamond strut shape, \(R_\mathrm{eq} =A_\mathrm{det}.\sqrt{\sqrt{3}/2\pi }\)

For a hexagon strut shape, \(R_\mathrm{eq} =A_\mathrm{h}.\sqrt{3\sqrt{3}/2\pi }\)

For a star (regular hexagram) strut shape, \(R_\mathrm{eq} =A_\mathrm{st} .\sqrt{3\sqrt{3}/\pi }\)

Rights and permissions

About this article

Cite this article

Kumar, P., Topin, F. Micro-structural Impact of Different Strut Shapes and Porosity on Hydraulic Properties of Kelvin-Like Metal Foams. Transp Porous Med 105, 57–81 (2014). https://doi.org/10.1007/s11242-014-0358-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-014-0358-8