Abstract

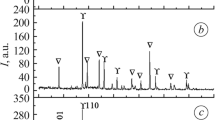

Ce x Ti1−x O n composites with different Ti:Ce molar ratios (from 95:05 up to 70:30) were prepared unconventionally, via the sol–gel process controlled within reverse micelles of nonionic surfactant and processing by pressurized hot and supercritical fluids in a flow regime as an alternative to common thermal treatment. Nitrogen physisorption, powder X-ray diffraction (XRD) combined with Rietveld/whole powder pattern modeling (WPPM) and organic elemental analysis (OEA) were used as tools for characterization of the porous structure morphology, structural and microstructural properties, and purity of the prepared composites. All prepared Ce x Ti1−x O n composites possessed well-developed mesoporous structure with minimum portion of micropores, showing specific surface area in the range of 203–256 m2/g. The experimental conditions during pressurized hot and supercritical processing as well as the Ce loading played a key role in crystallization of individual Ce x Ti1−x O n composites. With increasing Ce loading, crystallization of anatase at the expense of brookite was promoted, accompanied with decreasing microstrain in anatase crystallites. The elevated processing temperature (250 °C) led to crystallization of CeO2 cubic beside TiO2 anatase. As a consequence of the different solubility of the used surfactant in pressurized hot and supercritical solvents under pressures of 10 and 30 MPa, cubic CeO2 crystallites of different sizes were formed. This property of CeO2 crystallites crucially affected the recrystallization of Ce0.30Ti0.70O n -S composites at elevated temperatures; small and uniform CeO2 crystallites stabilized the anatase–cerianite phase mixture, giving rise to minor brookite phase.

Similar content being viewed by others

References

H.Q. Zhu, Z.F. Qin, W.J. Shan, W.J. Shen, J.G. Wang, J. Catal. 225, 267 (2004)

A.K. Sinha, K. Suzuki, J. Phys. Chem. B 109, 1708 (2005)

S. Ojala et al., Top. Catal. 54, 1224 (2011)

L. Matějová, P. Topka, K. Jirátová, O. Šolcová, Appl. Catal. A: Gen. 443, 40 (2012)

S. Pitkäaho, L. Matějová, S. Ojala, J. Gaálová, R.L. Keiski, Appl. Catal. B: Environ. 113–114, 150 (2012)

S. Pitkäaho, L. Matějová, K. Jirátová, S. Ojala, R.L. Keiski, Appl. Catal. B: Environ. 126, 215 (2012)

L. Matějová, P. Topka, L. Kaluža, S. Pithaäho, S. Ojala, J. Gaálová, R.L. Keiski, Appl. Catal. B: Environ. 142–143, 54 (2013)

F. Galindo, R. Gomez, M. Aguilar, J. Mol. Catal. A: Chem. 281, 119 (2008)

V. Štengl, S. Bakardijeva, N. Murafa, Mater. Chem. Phys. 114, 217 (2009)

N. Aman, P.K. Satapathy, T. Mishra, M. Mahato, N.N. Das, Mater. Res. Bull. 47, 179 (2012)

J. Xiao, T. Peng, R. Li, Z. Peng, JCh. Yan, Solid State Chem. 179, 1161 (2006)

C. Guzman, G. Del Angel, R. Gomez, F. Galindo Hernandez, C. Angelez Chabez, Catal. Today 166, 146 (2011)

A.M.T. Silva, C.G. Silva, G. Dražič, J.L. Faria, Catal. Today 144, 13 (2009)

A. Rapsomanikis, A. Apostolopoulou, E. Stathatos, P. Lianos, J. Photochem. Photobiol. A: Chem. 280, 46 (2014)

A. Fujishima, X. Zhang, D.A. Tryk, Surf. Sci. Rep. 63, 515 (2008)

A.L. Linsebigler, G.Q. Lu, J.T. Yates, Chem. Rev. 95, 735 (1995)

D.O. Scanlon et al., Nat. Mater. 12, 798 (2013)

I. Liu, H. Zhao, J.M. Andino, Y. Li, ACS Catal. 2, 1817 (2012)

T. Luttrell, S. Halpegamage, J. Tao, A. Kramer, E. Sutterm, M. Batzill, Sci. Rep. 4, 4043 (2014)

P.A. Morris Hotsenpiller, J.D. Bolt, W.E. Farneth, J.B. Lowekamp, G.S. Rohrer, J. Phys. Chem. B 102, 3216 (1998)

T. Ohno, K. Sarukawa, M. Matsumura, New J. Chem. 26, 1167 (2002)

H.G. Yang et al., Nature 453, 638 (2008)

L. Ye, J. Liu, L. Tian, T. Peng, L. Zan, Appl. Catal. B: Environ. 134–135, 60 (2013)

J. Pan, G. Liu, G.Q. Lu, H.-M. Cheng, Angew. Chem. Int. Ed. 50, 2133 (2011)

T. Xia, Y. Zhang, J. Murowchick, X. Chen, Catal. Today 225, 2 (2014)

W. Wang, Ch-H Lu, Y.-R. Ni, J.-B. Song, M.-X. Su, Z.-Z. Xu, Catal. Commun. 22, 19 (2012)

I. Justicia, P. Ordejon, G. Canto, J.L. Mozos, A. Figueras, Adv. Mater. 14, 1399 (2002)

U. Diebold, Surf. Sci. Rep. 48, 53 (2003)

J.N. Pan, B.L. Maschhoff, U. Diebold, T.E. Madey, J. Vac. Sci. Technol. A 10, 2470 (1998)

M.A. Henderson, W.S. Epling, C.L. Perkins, C.H.F. Peden, U. Diebold, J. Phys. Chem. B 103, 5328 (1999)

V. Štengl, S. Bakardjieva, N. Murafa, Mater. Chem. Phys. 114, 217 (2009)

G. Li, D. Zhang, J.C. Yu, Phys. Chem. Chem. Phys. 11, 3775 (2009)

M. Nasir, S. Bagwasi, Y. Jiao, F. Chen, B. Tian, J. Zhang, Chem. Eng. J. 236, 388 (2014)

L. Matějová, K. Kočí, M. Reli, L. Čapek, A. Hospodková, P. Peikertová, Z. Matěj, L. Obalová, A. Wach, P. Kustrowski, A. Kotarba, Appl. Catal. B: Environ. 152–153, 172 (2014)

S. Kityakarn, A. Worayingyong, A. Suramitr, M.F. Smith, Mater. Chem. Phys. 139, 543 (2013)

J. Fang, X. Bi, D. Si, Z. Jiang, W. Huang, Appl. Surf. Sci. 253, 8952 (2007)

D.A.H. Hanaor, C. Sorrell, J. Mater. Sci. 46, 855 (2011)

L. Matějová, V. Valeš, R. Fajgar, Z. Matěj, V. Holý, O. Šolcová, J. Solid State Chem. 198, 485 (2013)

Y. Liu, P. Fang, Y. Cheng, Y. Gao, F. Chen, Z. Liu, Y. Dai, Chem. Eng. J. 219, 478 (2013)

T. Masui, K. Fujiwara, K.I. Machida, G.Y. Adachi, T. Sakata, H. Mori, Chem. Mater. 9, 2197 (1997)

S. Tsunekawa, T. Fukuda, A. Kasuya, J. Appl. Phys. 87, 1318 (2000)

H.C. Yao, Y.F.Y. Yao, J. Catal. 86, 254 (1984)

A. Trovarelli, Catal. Rev. 38, 439 (1996)

J. Kaspar, P. Fornasiero, M. Graziani, Catal. Today 50, 285 (1999)

L. Matějová, Z. Matěj, R. Fajgar, T. Cajthaml, O. Šolcová, Mater. Res. Bull. 47, 3573 (2012)

S.J. Gregg, K.S.W. Sing, Adsorption. Surface Area and Porosity (Academic, New York, 1982)

P. Schneider, Appl. Catal. A 129, 157 (1995)

J.B. DeBoer, B.C. Lippens, B.G. Linsen, J.C.P. Broekhoff, A.V.D. Heuvel, T.J. Osinga, J. Colloid Interface Sci. 21, 405 (1966)

A. Lecloux, J.P. Pirard, J. Colloid Interface Sci. 70, 265 (1979)

E.P. Barret, L.G. Joyner, P.B. Halenda, J. Am. Chem. Soc. 73, 373 (1951)

NOVAwin Data Processing—Quantachrome Software, Quantachrome, USA

P. Scardi, M. Leoni, Acta Crystallogr. Sect. A: Found. Crystallogr. 58, 190 (2002)

Z. Matěj, R. Kužel, MStruct-program/library for MicroStructure analysis by powder diffraction. 2009

Z. Matej, R. Kuzel, L. Nichtova, Powder Diffr. 25, 125 (2010)

Z. Matěj, L. Matějová, R. Kužel, Powder Diffr. 28, 161 (2013)

P. Kluson, H. Luskova, T. Cajthaml, O. Solcova, Thin Solid Films 495, 18 (2006)

L. Matějová, T. Cajthaml, Z. Matěj, O. Benada, P. Klusoň, O. Šolcová, J. Supercrit. Fluids 52, 215 (2010)

H. Zhang, M. Finnegan, J.F. Banfield, Nano Lett. 1, 81 (2001)

H. Zhang, J.F. Banfield, J. Phys. Chem. B 104, 3481 (2000)

R.I. Penn, J.F. Banfield, Am. Miner. 83, 1077 (1998)

Acknowledgments

Financial support from the Grant Agency of the Czech Republic (project reg. no. 14-23274S) and the Ministry of Education, Youth, and Sports of the Czech Republic in the “National Feasibility Program I” (project reg. no. LO1208, “TEWEP”) is gratefully acknowledged. The authors also thank Zdeněk Matěj for highly valuable advice concerning XRD data evaluation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matějová, L., Brunátová, T. & Daniš, S. TiO2–CeO2 prepared by using pressurized and supercritical fluids: effect of processing parameters and cerium amount on (micro)structural and morphological properties. Res Chem Intermed 41, 9243–9257 (2015). https://doi.org/10.1007/s11164-015-1990-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-1990-9