Abstract

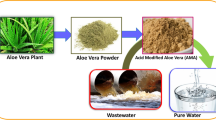

The removal of eight chlorophenols (2-CP, 3-CP, 4-CP, 2,3-DCP, 2,4-DCP, 2,5-DCP, 2,6-DCP and 2,4,6-TCP) using adsorption on activated carbon and adsorption in the presence of hydrogen peroxide was investigated. The influence of the pH, activated carbon dosage and hydrogen peroxide concentration were studied. The effects of the chlorine atom position and the chlorine content in the chlorophenol molecules on their degradation were also studied. The results revealed that the integration of the activated carbon and H2O2 treatment was more effective for the removal of the chlorophenols than using the activated carbon alone. The adsorption kinetics and adsorption efficiency increased with the increasing substitution of chlorine on the aromatic ring. The degradation rate and degradation efficiency of the chlorophenols using the activated carbon integrated with H2O2 decreased with the increasing chlorine atoms in the molecule. The combination of the activated carbon with hydrogen peroxide may significantly enhance the process and could offer an interesting alternative in wastewater treatment.

Similar content being viewed by others

Introduction

Chlorophenols (CPs) are among the most widespread pollutants of wastewater and natural waters. The presence of chloroorganic compounds in the aqueous environment including drinking water [1, 2] is a consequence of their use in a variety of industrial processes such as wood, fibre, paint and leather preservatives, for the manufacturing of pesticides and resins as well as for water disinfection [3]. Chlorophenols cause serious environmental problems, due to their high toxicity, strong odor emission, persistence in the environment and carcinogenic properties [4]. Thus, it is important to prevent their release into the environment and to study methods for their removal from contaminated sites.

Several methods are available for the removal of chlorinated phenols from water. Among them, biodegradation [5], oxidation by advanced oxidation processes [6] and adsorption [7, 8] are the most widely used. Advanced oxidation processes (AOPs) are based on the generation and use of powerful hydroxyl radicals (·OH) by means of chemical, photochemical or photocatalytic methods (Fenton, photo-Fenton, H2O2/O3, H2O2/UV, UV/O3, UV/TiO2) [6]. Adsorption has proven to be one of the most attractive and effective methods for removing chlorophenols from water, due to its low maintenance costs, high efficiency, simplicity of operation as well as the no or lower generation of toxic substances. Activated carbons (AC) are now the most commonly used adsorbents of the proven adsorption efficiency for organic pollutants due to their high surface area, pore volume, and pore size distribution [7, 8]. Activated carbons have also been used as heterogeneous catalysts and supports of catalysts [9]. It is well known that the hydrogen peroxide can be activated by AC (Eqs. 1 and 2) forming reactive free radicals that are able to oxidize organic contaminants.

In recent years, several authors reported that H2O2 in the presence of activated carbon could oxidize some pollutants such as methyl tert-butyl ether [10], trichloroethene [10], fulvic acids [11], dyes [12, 13], paraquat [14], cyanide [15], ethylene glycol [16], ampicillin [17] and chlorophenols [10, 18–20].

The effectiveness of the organic compound degradation depends on many factors, including the pH, temperature, H2O2 concentration as well as the physicochemical properties of the activated carbons, which affect the decomposition of the hydrogen peroxide. The H2O2 decomposition on the activated carbon is followed by the exchange of a hydroxyl group at the AC surface with a hydrogen peroxide anion (Eq. 3). The formed surface peroxide is regarded as having an increased oxidation potential which enables the decomposition of another hydrogen peroxide molecule releasing oxygen and regenerating the activated carbon group (Eq. 4) [10].

The degradation of the hydrogen peroxide depends on the nature of the activated carbon surface. The activated carbons of basic character promote a faster hydrogen peroxide decomposition whereas the presence of acidic surface oxygen groups inhibits the reaction [12, 18, 21]. Huang et al. [19] found that the decomposition of the H2O2 decreased with an increasing content of the acidic groups on the AC surface. The catalytic activity of AC toward the 4-CP followed the inverse sequence of the activity toward the H2O2. The acidic functional groups on the AC surface, decreased the loss of the H2O2 and reduced the effect of surface scavenging resulting in the increase of the 4-CP degradation efficiency [19]. A similar phenomenon was observed in the oxidation of the 2-chlorophenol [20]. Lücking et al. [18] reported that the decomposition of H2O2 during the oxidation of 4-chlorophenol in the AC/H2O2 system was slower than in the absence of 4-CP. This fact was a consequence of the adsorption of 4-CP which reduces the surface area of the AC available for the decomposition of the hydrogen peroxide. The decreasing of the particle size of the activated carbon also accelerates the kinetics of the hydrogen peroxide decomposition [22]. The porosity of the activated carbons (the extended surface areas or large pore volumes) did not enhance the decomposition of H2O2, but in fact reduced it [19, 21]. Nevertheless, the catalytic activity of some carbonaceous materials (carbon blacks and carbon nanotubes) toward 2-CP was enhanced with an increase in the specific surface area of the catalysts [20].

In most of the works, the authors studied the oxidation by hydrogen peroxide in the presence of the activated carbon or compared the catalytic properties of various activated carbons. These studies, however, concern only one compound (comparative studies for several compounds were rare). The effectiveness of the AC/H2O2 process was investigated only for a few selected chlorophenols including 2-CP [20], 4-CP [18, 19] and 2,4,5-trichlorophenol [10]. However, to the best knowledge, the other chlorophenols were not studied and were not compared to each other.

The aim of this study was to investigate the adsorption as well as the adsorption integrated with the H2O2 oxidation of eight chlorophenols. The effects of the pH, activated carbon dosage and hydrogen peroxide concentration were studied. The effects of the chlorine atom position and chlorine content in the chlorophenols molecules on their degradation were evaluated and discussed.

Materials and methods

Chemicals and reagents

The chlorophenols: 2-chlorophenol (2-CP), 3-chlorophenol (3-CP), 4-chlorophenol (4-CP), 2,3-dichlorophenol (2,3-DCP), 2,4-dichlorophenol (2,4-DCP), 2,5-dichlorophenol (2,5-DCP), 2,6-dichlorophenol (2,6-DCP) and 2,4,6-trichlorophenol (2,4,6-TCP) were purchased from Sigma-Aldrich (St. Louis, USA). Sodium hydroxide, hydrogen peroxide (30 %), sulfuric acid (95 %), acetic acid (99 %) and HPLC-grade acetonitrile were from Avantor Performance Materials (Gliwice, Poland).

The L2S powdered activated carbon (Ceca, France) was used in this experiment. The specific surface area (S BET), the micropore (V mi) and the mesopore (V me) volumes were 925 m2 g−1, 0.245 and 0.235 cm3 g−1 [23]. Prior to use, the activated carbon was dried in an oven at 120 °C to a constant weight and kept in a desiccator for further study.

Adsorption/oxidation procedure

The experiments were carried out in Erlenmeyer flasks containing 0.05 L of chlorophenol solution (0.5 mmol L−1) as well as appropriate amounts of hydrogen peroxide and activated carbon at various pH (3–11) and an agitation speed of 200 rpm at 25 °C. The effects of the pH, activated carbon dosage and hydrogen peroxide concentration were investigated. These experiments were conducted only for the 3-chlorophenol. It was established that the best conditions for the degradation of 3-CP will be optimal also for the other chlorophenols. Aqueous samples were taken at different intervals of time and the concentrations of chlorophenols were measured by high performance liquid chromatography. The amounts of adsorption/oxidation at the time t (q t, mmol g−1) and at equilibrium (q e, mmol g−1) were calculated by the following equations:

Here C 0, C t and C e are the initial concentration, concentration at time t and equilibrium concentration (after 6 h) of chlorophenol in the solution (mmol L−1), V is the volume of the solution (L) and m is the mass of the activated carbon (g).

All the experiments were carried out in triplicate under identical conditions and the average values were used for further calculations. The mean and standard deviation of the three replicates were reported and the data obtained were analyzed using t test and/or ANOVA with a Tukey test. The differences between any pair of the treatment means were tested using the least significant difference test with the significance level at 0.05.

Analytical method

The concentrations of the chlorophenols were measured by high performance liquid chromatography with UV detection (Shimadzu LC-20, Kyoto, Japan). The chromatographic conditions were as follows: mobile phase—acetonitrile/water adjusted to pH 3.0 with acetic acid (50/50, v/v), flow rate 0.25 mL min−1 and analytical wavelength 280 nm. The chromatographic analyses were carried out on a Phenomenex Luna C18, 2.0 × 150 mm, 3 μm column (Torrance, USA).

Results and discussion

In order to investigate the optimal chlorophenol degradation conditions, the effects of the pH, the activated carbon dosage and the hydrogen peroxide concentration were studied. 3-Chlorophenol was used as a model compound throughout the study.

Effect of pH

The effect of the pH on the 3-CP degradation was studied by varying the initial pH of the solutions from pH 3 to 11. The pH was adjusted (prior to the addition of the H2O2 and the AC) using 0.1 mol L−1 H2SO4 or 0.1 mol L−1 NaOH and was measured using a pH meter. The mass of the AC was fixed at 0.01 g and the initial concentrations of 3-CP and H2O2 were 0.5 and 5.0 mmol L−1, respectively. The results are presented in Fig. 1.

For the description of the experimental data, the equations of the pseudo-first [24] (Eq. 7) and pseudo-second order [25] (Eq. 8) were considered.

Here k 1 is the pseudo-first order rate constant (h−1) and k 2 is the pseudo-second order rate constant (g mmol−1 h−1). The values of k 1 and k 2 were calculated from the plots of log(q e − q t) versus t and t/q t versus t, respectively. All of the results obtained from the pseudo-first order kinetic model were weaker in each case, and therefore they were not taken into account and are not shown. For the comparison and interpretation of the results only the pseudo-second order rate constants were used.

The degradation rate of the 3-CP decreased with an increase in the pH from 3 to 11. The k 2 values obtained for the initial pH solutions of 3, 5, 7, 9 and 11 were 0.775, 0.554, 0.513, 0.267 and 0.156 g mmol−1 h−1. As can be seen, the pH affects not only the degradation rate of 3-CP but also its effectiveness. After 6 h, at pH 3, about 80 % of 3-CP was removed while at pH 11 only 10 %.

The relationship between the initial solution pH and the adsorption/oxidation of 3-CP at equilibrium (q e) is presented in Fig. 2. For comparative purposes, the experiments of the 3-CP adsorption on the activated carbon in the absence of hydrogen peroxide were also carried out under the same conditions (Fig. 2).

The removal of the 3-CP in the absence of H2O2 was almost constant at the acidic pH range of 3-7 and decreased with the further increasing in the pH (from pH 7 to 11). The q e value decreased with an increase in the pH from 3 to 11 from 0.997 to 0.190 mmol g−1. This dependence is associated with the pKa of the adsorbate (8.8) and pHPZC of the adsorbent. The point of zero charge (pHPZC) was determined by the pH drift method and was found to be 7.0. At a pH greater than the pKa value, 3-CP existed predominantly in anionic forms as a negatively charged phenolate anions. At the pH below the pHPZC, the surface of the AC was positively charged, while at a pH greater than pHPZC, the surface had a net negative charge. The results showed that the non-dissociated form of 3-CP was preferred by the positively charged surface of the activated carbon. The large reduction in 3-CP adsorption at highly basic conditions can be attributed to the electrostatic repulsion between the negatively charged AC and the dissociated 3-CP molecules. Similar results were reported for the adsorption of the 4-chlorophenol on the activated carbon prepared from rattan sawdust [26] and the Norit R3-ex granular activated carbon [27].

The influence of the pH on 3-CP removal by the AC/H2O2 is different, because the pH of the solution affects the nature of the chemical surface of the activated carbon but also the stability of the hydrogen peroxide. In acidic media, hydrogen peroxide is more stable; the higher decomposition is observed under the basic conditions. These facts explain the removal of 3-CP at different pH (Fig. 2). The results showed that 3-CP degradation using activated carbon and H2O2 decreased by increasing the pH. The best results were observed in the acid environment (pH 3) as a result of the higher stability and the higher redox potential of the hydrogen peroxide [18] as well as the high adsorption capacity of the activated carbon at low pH values. Similar observations (the most effective degradation of the 4-CP by AC/H2O2 at pH 3) have previously been described by Lücking et al. [18]. Khorramfar et al. [13] also reported that the Acid Red 18, Direct Red 80 and Reactive Red 194 dyes oxidation using the AC/H2O2 increased by decreasing the pH.

Since the lower pH favored the removal efficiency, in the following, chlorophenols degradation were studied at pH 3.

Effect of activated carbon dose

To investigate the effect of the activated carbon dosage on the chlorophenol degradation, different amounts of AC (0.005, 0.010, 0.015 and 0.020 g) were added to the Erlenmeyer flasks containing 0.05 L 3-CP solution (0.5 mmol L−1) and hydrogen peroxide (5.0 mmol L−1). The pH of the solution was set as 3.0 prior to the addition of the H2O2 and AC. The results are presented in Fig. 3.

The removal efficiency increased with an increase in the initial AC dosage from 50 % (0.005 g) to about 85 % (0.02 g). The degradation kinetics followed a pseudo-second order and the k 2 rate constants were found to increase with the AC dosage (0.281, 0.911, 1.522 and 1.788 g mmol−1 h−1 for the initial AC concentration of 0.005, 0.010, 0.015 and 0.020). An increase in 3-CP removal with the AC dosage can be attributed to the greater surface area and the availability of more adsorption sites. Moreover, the higher AC concentration leads to an increase in the number of active catalytic sites available for H2O2 decomposition.

Effect of H2O2 concentration

The effect of the hydrogen peroxide concentration was studied with an initial 3-CP concentration of 0.5 mmol L−1, for different [H2O2]/[3-CP] molar ratios equal to 1, 10, 50 and 100. The AC concentration was constant for all of the experiments (0.015 g) and the pH was 3.0. It can be observed in Fig. 4 that the removal efficiency of 3-CP raises with the increase of the H2O2 molar excess from 1 to 10. A further increase of the H2O2 dosage did not achieve a higher removal rate and efficiency. For the molar ratios of 1, 10, 50 and 100, 3-CP removal after 6 h was 84, 91, 78 and 76 %, and the k 2 values were as follows: 2.430, 3.275, 1.522 and 1.223 g mmol−1 h−1. These results agree with the earlier studies, which reported that an excessive concentration of hydrogen peroxide decreases the degradation efficiency of the organic compounds including ampicillin [17] and paraquat [14] by AC/H2O2. It may be due to the fact that some of the organic compounds and oxidation by-products were quickly removed by the adsorption and did not react with the H2O2, so they did not consume H2O2. Also, the more resistant by-products generated during the oxidation process could only be removed by the activated carbon, and as a result, a further increase of the H2O2 concentration did not improve the removal efficiency [17]. Dhaouadi and Adhoum [14] reported that the decrease in the oxidation efficiency observed at high H2O2 dosages may be due to its scavenging effect towards the hydroxyl radicals according to the following reactions:

This phenomenon causes a dramatic loss of hydrogen peroxide leading to oxidation inefficiency [14]. A negative impact of the excessive H2O2 concentration has previously been described by Ku et al. [28] who studied the decomposition rate of the 3-CP by sonolysis in the presence of hydrogen peroxide. The degradation rate of 3-CP (20 mg L−1) was kept high in the presence of 700 mg L−1 of H2O2. However, the degradation rate was slightly decreased for the experiment conducted with the presence of 1000 mg L−1 of hydrogen peroxide [28]. On that basis, a 5.0 mmol L−1 concentration of H2O2 was used for subsequent studies.

Removal of chlorophenols by AC and AC/H2O2

The removal efficiency and kinetics of eight chlorophenols in aqueous solution were investigated. The effects of the chlorine position and chlorine content in the chlorophenol molecules on their degradation were evaluated. All of the experiments were conducted under the same conditions (temperature 25 °C, agitation rate 200 rpm, pH 3.0, mass of the AC = 0.015 g, initial concentration of the CP = 0.5 mmol L−1, initial concentration of H2O2 = 5.0 mmol L−1). The non-catalytic oxidation with H2O2, the adsorption on the activated carbon, as well as the oxidation with H2O2 in the presence of the activated carbon were studied. The hydrogen peroxide decomposition by the activated carbon was not tested because in all of the experiments only one AC was used (L2S Ceca).

The oxidation of the chlorophenols with H2O2 in the absence of the activated carbon was not significant [data not shown]. During the considered period of time (6 h), the amounts of the CPs in the solution were constant. The concentrations varied ±3 %, which was due to the measurement error rather than the oxidation of the chlorophenols by the hydrogen peroxide. The removal of the chlorophenols by the AC and the AC/H2O2 as a function of time is presented in Fig. 5. The values of the k 2 kinetic constants, the q e and percentage removal after 6 h are listed in Table 1.

The results revealed that the increasing of the degree of chlorine substitution on the phenol ring increased the adsorption rate and adsorption efficiency of the CPs on the activated carbon. The adsorption of the CPs increased in the order monochlorophenols < dichlorophenols < trichlorophenol, which was correlated with the respective increase in the molecular mass, hydrophobicity and the decrease in the solubility. Similar results were reported by other authors [29–32]. The differences in the k 2 and q e values between the mono-, di- and TCP were statistically significant. However, the differences between the individual monochlorophenols (2-CP, 3-CP and 4-CP) as well as the dichlorophenols (2,3-DCP, 2,4-DCP, 2,5-DCP and 2,6-DCP) were not significantly different (ANOVA-Tukey test).

The combination of the activated carbon and hydrogen peroxide increased the removal of the chlorophenols in comparison with the single AC adsorption. The degradation order of the CPs by AC/H2O2 was 3-CP > 4-CP > 2-CP > 2,3-DCP ≥ 2,5-DCP ≥ 2,6-DCP ≥ 2,4-DCP > 2,4,6-TCP. For comparison, Tang and Huang [33] reported that the oxidation rates decreased in the order 3-CP > 2-CP > 4-CP > 2,5-DCP > 3,5-DCP > 2,3-DCP > 2,6-DCP > 2,4-DCP > 2,4,6-TCP for Fenton’s reagent. The oxidation kinetics of the chlorophenols in the aqueous solution with the potassium permanganate followed the sequence 2-CP > 2,6-DCP > 4-CP > 2,4-DCP > 3-CP [34]. For the single photodecomposition produced by the polychromatic UV irradiation and oxidation by the combined UV/H2O2 system, Benitez et al. [35] found that the oxidation rates decrease in the order 4-CP > 2,4-DCP > 2,4,6-TCP. On the other hand, Hugül et al. [36] reported that the degradation order of CPs was 2,4,6-TCP ≥ 2,4-DCP > 2-CP for the UV-catalyzed oxidation with the H2O2. Zhou et al. [37] described the oxidation of the chlorophenols with the H2O2 catalyzed by the Cu–Al hydrotalcite/clay composite. They found that the content and position of the chlorine on the aromatic ring had significantly different effects on the oxidation rate of the CPs, with the rate sequence of 3-CP > 2-CP > 4-CP > 3,5-DCP > 3,4-DCP > 2,5-DCP > 2,4-DCP > 2,6-DCP > 2,4,5-TCP. Simon et al. [38] investigated the effect of chlorine substituents on the oxidation of all 19 chlorophenols by cerium(IV). The oxidation rate constants of the chlorophenols (used in this paper only) decreased in the order 4-CP > 3-CP > 2,4,6-TCP > 2,5-DCP > 2,3-DCP ≥ 2-CP > 2,4-DCP > 2,6-DCP. 2,4,6-Trichlorophenol was removed faster than all of the dichlorophenols and 2-CP, but the authors found that 2,4,6-TCP showed a substantially different behavior than other chlorophenols. In general, the ortho- substitution decreased the reactivity, the meta- substitution had no significant effect on the reactivity while the para- substitution increased the reactivity in the cerium(IV) oxidation [38].

These examples suggest that the chlorine substitution on the aromatic ring could cause many different effects on the reactivity of the chlorophenols for the different oxidation methods.

Based on the results obtained in this work, it can be concluded that the reactivity of the chorophenols decreases with the increasing substitution of the chlorine on the aromatic ring. The oxidation of the monochlorophenols was faster than that of the dichlorophenols, which were oxidized more easily than the trichlorophenol. The differences between the mono- and di-, between mono- and tri- as well as between monochlorophenols and trichlorophenol were statistically significant (ANOVA-Tukey test). Increasing the degree of the Cl content decreases the solubility of the chlorophenols. As suggested by Tang and Huang [39], the increase in the hydrophobicity of the chlorophenols decreases the probability of the molecules encountered by the hydroxyl radical attack due to the non-dissolved CPs, resulting in an increase in the recombination rate of the hydroxyl radicals and, in consequence, a reduction in the oxidation rate of the organic compounds. Moreover, the increase of the chlorine atoms number in the molecules can block some favorable positions susceptible to the hydroxyl radical attack and, as a consequence, decrease the effectiveness of the chlorophenols oxidation [38].

The results showed also that the chlorine position of the chlorophenols has a significant effect on the degradation rate. The values of k 2 for 2-CP, 3-CP and 4-CP were 2.744, 3.294 and 2.982 g mmol−1 h−1, respectively. At the 0.05 level, the differences of the k 2 values were significantly different. The removal of the 3-CP was faster than that of the 4-CP, which was degraded more easily than the 2-CP. The oxidation rate may be influenced by the interaction of the electron-withdrawing chlorine and the hydroxyl groups, the resonance of the phenolic anion and the steric effect of the chlorine. The attack of the free radicals is more favorable at the ortho- and para- positions of the benzene ring structure. The chlorine atom at the ortho- position strongly inhibits the oxidation of the C–OH to C=O by the steric hindrance effect; while the Cl atom at the para- position might inhibit the oxidation of the C–Cl to C=O by both the σ-electron withdrawing conductive effect and dechlorination [37]. Therefore, the higher degradation rate of the 3-CP is due to the fact that the benzene ring structure of the 3-CP provides one more site than those of 2-CP and 4-CP available for the free radical attack. A similar observation was reported by Tang and Huang [33] and by Zhou et al. [37]. Ku et al. [28] also reported that the decomposition rates of 3-CP by sonolysis were higher than those for the 2- and 4-chlorophenol. As shown in Table 1, 4-CP was removed faster than 2-CP by the AC/H2O2. 2-Chlorophenol was more resistant than 4-CP because 2-CP have some steric hindrance effect due to the closer location between the –OH and the –Cl groups on the aromatic ring than that on 4-CP [33].

The oxidation rate of the dichlorophenols depends on the directory effect of the –OH and the –CI groups and the steric hindrance of the chlorine atoms [33]. The chlorine blocked at the ortho- position will decrease the dechlorination rate constants more than the chlorine atom blocked at the meta- position. The more Cl atoms existing on the aromatic ring especially at the ortho- and para- position makes the molecule more stable and more difficult for the oxidation [33]. The removal rate of the DCPs by the activated carbon in the presence of the H2O2 followed the sequence 2,3-DCP ≥ 2,5-DCP ≥ 2,6-DCP ≥ 2,4-DCP. The differences between all of the dichlorophenols were small and were not statistically significant.

It is found that 2,4,6-TCP was the most resistant to oxidation. This is due to the fact that the chlorine atoms in the molecule prevent the hydroxyl radical attack on the unoccupied sites of the aromatic ring.

The removal of the CPs by the AC/H2O2 was a combination of oxidation and adsorption. In general, the degradation of the chlorophenols by the activated carbon integrated with the hydrogen peroxide was more effective and faster in comparison with the single AC adsorption. The differences in the k 2 and q e values between the same chlorophenols obtained during their removal on the activated carbon and on the activated carbon in the presence of H2O2 were statistically significant (p < 0.05). Only the q e values obtained for the 2,4,6-TCP adsorption (1.281 ± 0.028 mmol g−1) and the adsorption integrated with H2O2 (1.340 ± 0.053 mmol g−1) were not statistically significant (p = 0.166).

The percentage removal of 3-CP, after 6 h, in the AC/H2O2 was 90.5 % (60.2 % of the 3-CP was adsorbed and 30.3 % was oxidized). Under the same experimental conditions, the removal of 2,4,6-TCP was found to be 86.2 % (80.5 % was adsorbed and 5.7 % was oxidized). This suggests that in the process, the adsorption played a dominant role.

The important part of the oxidative studies is identification of the oxidation products and intermediates. This is important because these compounds could also be toxic and moreover, their presence could affect the chlorophenols degradation rate and efficiency. A variety of reaction by-products were observed to form during the oxidation of chlorophenols (e.g. phenols, quinones, catechols) and the degradation pathways and mechanisms for many of the oxidation processes have been proposed [37, 40–44]. Unfortunately, in this work, during the oxidation experiments, the additional peaks on the chromatograms were not observed, suggesting that the oxidation intermediates were rapidly adsorbed on the activated carbon. The adsorption of the by-products formed during the oxidation of chlorophenols in AC/H2O2 system was demonstrated by Huang et al. [19] who studied the relationship between the total reduction of 4-CP and dissolved organic carbon in suspension. They found that the decrease of dissolved organic carbon was similar to the total reduction of 4-CP, indicating that the chlorophenol and its oxidation by-products were almost adsorbed further onto activated carbon surface [19].

Conclusions

The removal of eight chlorophenols by the adsorption on the activated carbon and using activated carbon in the presence of H2O2 was investigated. The effects of the operational parameters including the pH, activated carbon dosage and hydrogen peroxide concentration were studied. The influence of the chlorine position and the chlorine content in the chlorophenol molecules on their degradation were also studied. The results showed that the increasing of the degree of the chlorine substitution on the phenol ring increased the adsorption kinetics and the adsorption efficiency of the CPs on the activated carbon with the rate sequence of monochlorophenols < dichlorophenols < trichlorophenol. The integration of the activated carbon and the H2O2 treatment was more effective for the removal of the CPs than using the activated carbon alone. The chlorine content and the position on the aromatic ring had a significant effect on the chlorophenols removal. 3-CP was removed faster and more effectively than 4-CP, which was oxidized more easily than 2-CP. The CP degradation rate and degradation efficiency decreased with the increasing substitution of the chorine on the aromatic ring (mono- > di- > trichlorophenol). The combination of both the adsorption and the heterogeneous catalysis (AC/H2O2) could be used as an eco-friendly process for wastewater treatment.

References

Michałowicz J (2005) The occurrence of chlorophenols, chlorocatechols and chlorinated methoxyphenols in drinking water of the largest cities in Poland. Pol J Environ Stud 14:327–333

Michałowicz J, Stufka-Olczyk J, Milczarek A, Michniewicz M (2011) Analysis of annual fluctuations in the content of phenol, chlorophenols and their derivatives in chlorinated drinking waters. Environ Sci Pollut Res 18:1174–1183

Czaplicka M (2004) Sources and transformations of chlorophenols in the natural environment. Sci Total Environ 322:21–39

Igbinosa EO, Odjadjare EE, Chigor VN, Igbinosa IH, Emoghene AO, Ekhaise FO, Igiehon NO, Idemudia OG (2013) Toxicological profile of chlorophenols and their derivatives in the environment: the public health perspective. Sci World J 2013:1–11. Article ID 460215

Olaniran AO, Igbinosa EO (2011) Chlorophenols and other related derivatives of environmental concern: properties, distribution and microbial degradation processes. Chemosphere 83:1297–1306

Pera-Titus M, Garcia-Molina V, Baños MA, Giménez J, Esplugas S (2004) Degradation of chlorophenols by means of advanced oxidation processes: a general review. Appl Catal B Environ 47:219–256

Dąbrowski A, Podkościelny P, Hubicki Z, Barczak M (2005) Adsorption of phenolic compounds by activated carbon-a critical review. Chemosphere 58:1049–1070

Soto ML, Moure A, Dominguez H, Parajo JC (2011) Recovery, concentration and purification of phenolic compounds by adsorption: a review. J Food Eng 105:1–27

Rodríguez-Reinoso F (1998) The role of carbon materials in heterogeneous catalysis. Carbon 36:159–175

Georgi A, Kopinke FD (2005) Interaction of adsorption and catalytic reactions in water decontamination processes Part I. Oxidation of organic contaminants with hydrogen peroxide catalyzed by activated carbon. Appl Catal B Environ 58:9–18

Klimenko NA, Savchina LA, Polyakova TV, Kozyatnik IP (2009) Adsorption-catalytic removal of fulvic acids on activated carbons in the presence of hydrogen peroxide. J Water Chem Technol 31(2):92–97

Santos VP, Pereira MFR, Faria PCC, Orfao JJM (2009) Decolourisation of dye solutions by oxidation with H2O2 in the presence of modified activated carbons. J Hazard Mater 162:736–742

Khorramfar S, Mahmoodi NM, Arami M, Bahrami H (2011) Oxidation of dyes from colored wastewater using activated carbon/hydrogen peroxide. Desalination 279:183–189

Dhaouadi A, Adhoum N (2010) Heterogeneous catalytic wet peroxide oxidation of paraquat in the presence of modified activated carbon. Appl Catal B Environ 97:227–235

Yeddou AR, Nadjemi B, Halet F, Ould-Dris A, Capart R (2010) Removal of cyanide in aqueous solution by oxidation with hydrogen peroxide in presence of activated carbon prepared from olive stones. Miner Eng 23:32–39

Bach A, Semiat R (2011) The role of activated carbon as a catalyst in GAC/iron oxide/H2O2 oxidation process. Desalination 273:57–63

Wang G, Wu T, Li Y, Sun D, Wang Y, Huang X, Zhang G, Liu R (2012) Removal of ampicillin sodium in solution using activated carbon adsorption integrated with H2O2 oxidation. J Chem Technol Biotechnol 87:623–628

Lücking F, Köser H, Jank M, Ritter A (1998) Iron powder, graphite and activated carbon as catalysts for the oxidation of 4-chlorophenol with hydrogen peroxide in aqueous solution. Water Res 32(9):2607–2614

Huang HH, Lu MC, Chen JN, Lee CT (2003) Catalytic decomposition of hydrogen peroxide and 4-chlorophenol in the presence of modified activated carbons. Chemosphere 51:935–943

Kuśmierek K, Świątkowski A (2015) Degradation of 2-chlorophenol in aqueous solutions in presence of hydrogen peroxide and various carbon materials. Przem Chem 94(12):2126–2129

Khalil LB, Girgis BS, Tawfik TAM (2001) Decomposition of H2O2 on activated carbon obtained from olive stones. J Chem Technol Biotechnol 76:1132–1140

Aguinaco A, Pocostales JP, Garcıa-Araya JF, Beltran FJ (2011) Decomposition of hydrogen peroxide in the presence of activated carbons with different characteristics. J Chem Technol Biotechnol 86:595–600

Kuśmierek K, Sankowska M, Skrzypczyńska K, Świątkowski A (2015) The adsorptive properties of powdered carbon materials with a strongly differentiated porosity and their applications in electroanalysis and SPME-GC. J Colloid Interface Sci 446:91–97

Lagergren S (1898) Theorie der sogenannten adsorption geloester stoffe. Vetenskapsakad Handl 24:1–39

Ho YS, McKay G (1999) Pseudo-second-order model for sorption processes. Process Biochem 34:451–465

Hameed BH, Chin LH, Rengaraj S (2008) Adsorption of 4-chlorophenol onto activated carbon prepared from rattan sawdust. Desalination 225:185–198

Kuśmierek K, Świątkowski A (2015) Influence of pH on adsorption kinetic of monochlorophenols from aqueous solutions on granular activated carbon. Ecol Chem Eng S 22(1):95–105

Ku Y, Tu YH, Ma CM (2005) Effect of hydrogen peroxide on the decomposition of monochlorophenols by sonolysis in aqueous solution. Water Res 39:1093–1098

Hamdaoui O, Naffrechoux E (2007) Modeling of adsorption isotherms of phenol and chlorophenols onto granular activated carbon. Part I: two-parameter models and equations allowing determination of thermodynamic parameters. J Hazard Mater 147:381–394

Wu FC, Tseng RL, Huang SC, Juang RS (2009) Characteristics of pseudo-second-order kinetic model for liquid-phase adsorption: a mini-review. Chem Eng J 151:1–9

Liu QS, Zheng T, Wang P, Jiang JP, Li N (2010) Adsorption isotherm, kinetic and mechanism studies of some substituted phenols on activated carbon fibers. Chem Eng J 157:348–356

Hossain GSM, McLaughlan RG (2012) Sorption of chlorophenols from aqueous solution by granular activated carbon, filter coal, pine and hardwood. Environ Technol 33(16):1839–1846

Tang WZ, Huang CP (1995) The effect of chlorine position of chlorinated phenols on their dechlorination kinetics by Fenton’s reagent. Waste Manag 15(8):615–622

Hossain SMG, McLaughlan RG (2012) Oxidation of chlorophenols in aqueous solution by excess potassium permanganate. Water Air Soil Pollut 223:1429–1435

Benitez FJ, Beltran-Heredia J, Acero JL, Rubio FJ (2001) Oxidation of several chlorophenolic derivatives by UV irradiation and hydroxyl radicals. J Chem Technol Biotechnol 76:312–320

Hugül M, Apak R, Demirci S (2000) Modeling the kinetics of UV/hydrogen peroxide oxidation of some mono-, di-, and trichlorophenols. J Hazard Mater B77:193–208

Zhou S, Gu C, Qian Z, Xu J, Xia C (2011) The activity and selectivity of catalytic peroxide oxidation of chlorophenols over Cu–Al hydrotalcite/clay composite. J Colloid Interface Sci 357:447–452

Simon A, Ballai C, Lente G, Fábián I (2011) Structure–reactivity relationships and substituent effect additivity in the aqueous oxidation of chlorophenols by cerium(IV). New J Chem 35:235–241

Tang WZ, Huang CP (1996) Effect of chlorine content of chlorinated phenols on their oxidation kinetics by Fenton’s reagent. Chemosphere 33:1621–1635

Hirvonen A, Trapido M, Hentunen J, Tarhanen J (2000) Formation of hydroxylated and dimeric intermediates during oxidation of chlorinated phenols in aqueous solution. Chemosphere 41:1211–1218

Lente G, Espenson JH (2004) A kinetic study of the early steps in the oxidation of chlorophenols by hydrogen peroxide catalyzed by a water-soluble iron(III) porphyrin. New J Chem 28:847–852

Zhou T, Li Y, Ji J, Wong FS, Lu X (2008) Oxidation of 4-chlorophenol in a heterogeneous zero valent iron/H2O2 Fenton-like system: kinetic, pathway and effect factors. Sep Purif Technol 62:551–558

Kucharska M, Naumczyk J (2009) Degradation of selected chlorophenols by advanced oxidation processes. Environ Protect Eng 35(2):47–55

Biniak S, Świątkowski A, Pakuła A, Kuśmierek K, Trykowski G (2015) Electro-oxidation of chlorophenols on powdered carbon electrodes of different porosity. React Kinet Mech Cat 114:369–383

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kuśmierek, K. The removal of chlorophenols from aqueous solutions using activated carbon adsorption integrated with H2O2 oxidation. Reac Kinet Mech Cat 119, 19–34 (2016). https://doi.org/10.1007/s11144-016-1039-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-016-1039-0