Abstract

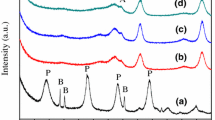

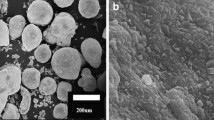

Palm oil catalytic cracking over a mesoporous aluminosilicate material (Al-MCM-41) containing 5 % alumina was studied in order to evaluate the Langmuir–Hinshelwood (LH) kinetic parameters. The Al-MCM-41 catalyst was prepared by the sol–gel technique and was characterized by X-ray diffraction and nitrogen adsorption techniques. The Brunauer–Emmett–Teller surface area of the catalyst was found to be 1,278 m2g−1. A 400 mL stirred batch autoclave reactor was used for catalytic cracking of 100 g refined palm oil and 1 g catalyst at a reaction temperature ranging from 573 to 673 K. The pressure–time data at different reaction temperatures were analyzed statistically in order to minimize experimental errors in the recorded pressures, whereas the statistically predicted pressure data were used to calculate the kinetic parameters. It was found that the fitting quality of the statistical model data using the LH model is similar to that of the raw experimental data. However, the values of the predicted parameters are significantly different. The estimated activation energy from LH kinetics was found to be 87 and 112 kJ mol−1 calculated from statistical model data and raw experimental data, respectively. The predicted parameters obtained from statistical model data are found to be more accurate as the influence of experimental error is minimized prior to data analysis.

Similar content being viewed by others

References

Olusola J, Adediran M, Oluseyi A, Ajao U (2010) Processing of triglycerides to diesel range hydrocarbon fuels: easily practicable small scale approach. Energy Environ 21(1):1325–1342

Demirbas A (2009) Progress and recent trends in biodiesel fuels. Energy Convers Manage 50:14–34

Rutz D, Janssen R (2008) Biofuel technology handbook. WIP renewable energies, sylvensteinstr, 2nd edn. Germany, Munchen

Singh S, Singh D (2010) Biodiesel production through the use of different sources and characterization of oils and their esters as the substitute of diesel: a review. Renew Sustain Energy Rev 14:200–216

Twaiq FA, Mohamed AR, Bhatia S (2003) Liquid hydrocarbon fuels from palm oil by catalytic cracking over aluminosilicate mesoporous catalysts with various Si/Al ratios. Microporous Mesoporous Mater 64:95–107

Yared I, Kurniawan H, Wibisono N, Sudaryanto Y, Hindarso H, Ismadji S (2008) Modeling of liquid hydrocarbon fuel production from palm oil via catalytic cracking using MCM-41 as catalyst. ARPN J Eng Appl Sci 2:55–62

Prakash N, Karunanithi T (2008) Kinetic modeling in biomass pyrolysis—a review. Appl Sci Res 12:1627–1636

Guo Z, Wang S, Yin Q, Xu G, Luo Z, Cen K, Fransson T (2011) Catalytic cracking characteristics of bio-oil molecular distillation fraction. World Renewable Energy Congress 2011; Linkoping: Sweden

Twaiq FA, Zabidi NA, Bhatia S (1999) Catalytic conversion of palm oil to hydrocarbons: performance of various zeolite catalysts. Ind Eng Chem Res 38:3230–3237

Charusiri W, Vitidsant T (2005) Kinetic study of used vegetable oil to liquid fuels over sulfated zirconia. Energy Fuels 19:1783–1789

Ooi YS, Zakaria R, Mohamed AR, Bhatia S (2004) Hydrothermal stability and catalytic activity of mesoporous aluminum-containing SBA-15. Catal Commun 5:441–445

Stoltze P (2000) Microkinetic simulation of catalytic reactions. Prog Surf Sci 65:65–150

Gal T, Lakatos BG (2008) Thermal cracking of recycled hydrocarbon gas-mixtures for re-pyrolysis: operational analysis of some industrial furnaces. Appl Therm Eng 28:218–225

Demirbas A (2003) Fuel conversional aspects of palm oil and sunflower oil. Energy Sour 25:457–466

Kubatova A, Luo Y, Stavova J, Sadrameli S, Aulich T, Kozliak E, Seames W (2011) New path in the thermal cracking of triacylglycerols (canola and soybean oil). Fuel 90:2598–2608

Twaiq FA, Mohamed AR, Bhatia S (2007) Catalytic cracking of palm oil: kinetic study. Int J Energy Clean Environ 8:65–79

Zhang M, Chen H, Gao Y, He R, Yang H, Wang H, Zhang S (2010) Experimental study on bio-oil pyrolysis/gasification. Bioresources 5:135–146

Roelof L, Coetzer J, Pirow Engelbrecht J, Christo Crause J, Lin DK (2010) Statistical robustness study for kinetic models. Ind Chem Eng Res 49:2932–2942

Wilkinson GN (1961) Statistical estimations in enzyme kinetics. Biochem J 80:324–332

Moffitt JR, Chemla YR, Bustamane C (2010) Methods in statistical kinetics. Methods Enzymol 475:221–257

Bhatia S, Mohamed AR, Noor Shah AA (2009) Composites as cracking catalysts in the production of biofuel from palm oil: deactivation studies. Chem Eng J 155:347–354

Ooi YS, Zakaria R, Mohamed AR, Bhatia S (2004) Catalytic cracking of used palm oil and palm oil fatty acids mixture for the production of liquid fuel: kinetic modeling. Energy Fuels 18:1555–1561

Vasanth Kumar K, Porkodi K, Rocha F (2008) Langmuir–Hinshelwood kinetics—a theoretical study. Catal Commun 9:82–84

Fogler HS (2006) Elements of chemical reaction engineering, 4th edn. NY, Prentice Hall

Faundez JM, Garcia XA, Gordon AL (2001) A kinetic approach to catalytic pyrolysis of tars. Fuel Process Technol 69:239–256

Biswas S, Sharma D (2013) Studies on cracking of Jatropha oil. J Anal Appl Pyrolysis 99:122–129

Melo ACR, Araujo AS, Silva EFB, Oliveira RM, Fernandes VJ Jr, Luz G Jr, Jr Luz, Souza SG (2011) Kinetic behavior of sunflower oil pyrolysis over mesoporous materials. Fuel Process Technol 92:1340–1344

Acknowledgments

The financial support was granted by The Research Council (TRC), Sultanate of Oman (Project: ORG/EI/10/005). Catalyst characterization was conducted at CombiCat research centre (University Malaya, Malaysia).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Twaiq, F., Nasser, M.S. & Onaizi, S.A. Langmuir–Hinshelwood kinetic study for palm oil catalytic cracking over Al-MCM-41. Reac Kinet Mech Cat 112, 477–488 (2014). https://doi.org/10.1007/s11144-014-0701-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-014-0701-7