Abstract

Purpose

Twin screw hot melt granulation (TS HMG) is a valuable, but still unexplored alternative to continuous granulation of moisture sensitive drugs. However, knowledge of the material behavior during TS HMG is crucial to optimize the formulation, process and resulting granule properties. The aim of this study was to evaluate the agglomeration mechanism during TS HMG using a rheometer in combination with differential scanning calorimetry (DSC).

Methods

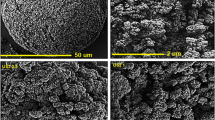

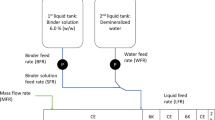

An immiscible drug-binder formulation (caffeine-Soluplus®) was granulated via TS HMG in combination with thermal and rheological analysis (conventional and Rheoscope), granule characterization and Near Infrared chemical imaging (NIR-CI).

Results

A thin binder layer with restricted mobility was formed on the surface of the drug particles during granulation and is covered by a second layer with improved mobility when the Soluplus® concentration exceeded 15% (w/w). The formation of this second layer was facilitated at elevated granulation temperatures and resulted in smaller and more spherical granules.

Conclusion

The combination of thermal and rheological analysis and NIR-CI images was advantageous to develop in-depth understanding of the agglomeration mechanism during continuous TS HMG and provided insight in the granule properties as function of process temperature and binder concentration.

Similar content being viewed by others

Abbreviations

- API:

-

Active pharmaceutical ingredient

- ATR:

-

Attenuated Total Reflection

- CAF:

-

Caffeine anhydrous

- CD:

-

Controlled deformation

- DSC:

-

Differential scanning calorimetry

- FTIR:

-

Fourier Transform Infrared

- G*:

-

Complex shear modulus

- G’:

-

Storage modulus

- G”:

-

Loss modulus

- GSD:

-

Granule size distribution

- HMG:

-

Hot melt granulation

- MCT:

-

Mercury-Cadmium-Telluride

- MPT:

-

Metoprolol tartrate

- NIR:

-

Near Infrared

- NIR-CI:

-

Near Infrared chemical imaging

- PEG:

-

Polyethylene glycol

- PVA:

-

Polyvinyl acetate

- SG:

-

Savitzky Golay

- SLP:

-

Soluplus®

- SNV:

-

Standard Normal Variate

- Tg :

-

Glass transition temperature

- Tm :

-

Melting temperature

- TS HMG:

-

Twin screw hot melt granulation

References

Kowalski J, Kalb O, Joshi YM, Serajuddin ATM. Application of melt granulation technology to enhance stability of a moisture sensitive immediate-release drug product. Int J Pharm. 2009;381:56–61.

Lakshman JP, Kowalski J, Vasanthavada M, Tong W-Q, Joshi YM, Serajuddin ATM. Application of melt granulation technology to enhance tabletting properties of poorly compactible high-dose drugs. J Pharm Sci. 2011;100(4):1553–65.

Vervaet C, Remon JP. Continuous granulation in the pharmaceutical industry. Chem Eng Sci. 2005;60:3949–57.

Plumb K. Major challenges for the pharmaceutical industry pharmaceutical industry in the new. Pharmacia. 2004;70:1–32.

Vercruysse J, Cordoba Diaz D, Peeters E, Fonteyne M, Delaet U, Van Assche I, et al. Continuous twin screw granulation: Influence of process variables on granule and tablet quality. Eur J Pharm Biopharm. 2012;82(1):205–11.

Mu B, Thompson MR. Examining the mechanics of granulation with a hot melt binder in a twin-screw extruder. Chem Eng Sci. 2012;81:46–56.

Weatherley S, Mu B, Thompson MR, Sheskey PJ, O’Donnell KP. Hot-melt granulation in a twin screw extruder: Effects of processing on formulations with caffeine and ibuprofen. J Pharm Sci. 2013;102:4330–6.

Iveson SM, Litster JD, Hapgood K, Ennis BJ. Nucleation, growth and breakage phenomena in agitated wet granulation processes: A review. Powder Technol. 2001;117(1–2):3–39.

Schaefer T, Mathiesen C. Melt pelletization in a high shear mixer. VIII. Effects of binder viscosity. Int J Pharm. 1996;139:125–38.

Johansen A, Schaefer T. Effects of interactions between powder particle size and binder viscosity on agglomerate growth mechanisms in a high shear mixer. Eur J Pharm Sci. 2001;12:297–309.

Abberger T, Seo A, Schaefer T. The effect of droplet size and powder particle size on the mechanisms of nucleation and growth in fluid bed melt agglomeration. Int J Pharm. 2002;249(1–2):185–97.

Patel RP, Suthar AM. Ensuring better control of granulation. Eur J Pharm Sci. 2008;21:533–43.

Eliasen H, Schaefer T, Gjelstrup Kristensen H. Effects of binder rheology on melt agglomeration in a high shear mixer. Int J Pharm. 1998;176:73–83.

Ennis BJ. Theory of granulation: an engineering perspective. Handbook Pharm Granulation Technol. 2010;3:6–58.

Aho J, Boetker JP, Baldursdottir S, Rantanen J. Rheology as a tool for evaluation of melt processability of innovative dosage forms. Int J Pharm. 2015.

Monteyne T, Heeze L, Oldörp K, Vervaet C, Remon J.-P, Beer TD, et al. Vibrational spectroscopy to support the link between rheology and continuous twin-screw melt granulation on molecular level: a case study. Eur J Pharm Biopharm. 2016.

Gupta SS, Meena A, Parikh T, Serajuddin ATM. Investigation of thermal and viscoelastic properties of polymers relevant to hot melt extrusion - I : Polyvinlypyrrolidone and related polymers. J Excipients Food Chem. 2014;5(1):32–45.

De Graef V, Dewettinck K, Verbeken D, Foubert I. Rheological behavior of crystallizing palm oil. Eur J Lipid Sci Technol. 2006;108(10):864–70.

Nunez-Regueira L, Gracia-Fernandez CA, Gomez-Barreiro S. Use of rheology, dielectric analysis and differential scanning calorimetry for gel time determination of a thermoset. Polymer. 2005;46(16):5979–85.

Cruz J, Bautista M, Manuel J, Blanco M. NIR-chemical imaging study of acetylsalicylic acid in commercial tablets. Talanta. 2009;80:473–8.

Vercruysse J, Toiviainen M, Fonteyne M, Helkimo N, Ketolainen J, Juuti M, et al. Visualization and understanding of the granulation liquid mixing and distribution during continuous twin screw granulation using NIR chemical imaging. Eur J Pharm Biopharm. 2014;86(3):383–92.

Cespi M, Casettari L, Palmieri GF, Perinelli DR, Bonacucina G. Rheological characterization of polyvinyl caprolactam-polyvinyl acetate-polyethylene glycol graft copolymer (Soluplus®) water dispersions. Colloid Polym Sci. 2014;292(1):235–41.

Caron V, Tajber L, Corrigan OI, Healy AM. A comparison of spray drying and milling in the production of amorphous dispersions of sulfathiazole/polyvinylpyrrolidone and sulfadimidine/polyvinylpyrrolidone. Mol Pharm. 2011;8(2):532–42.

Hubert S, Briancon S, Hedoux A, Guinet Y, Paccou L, Fessi H, et al. Process induced transformations during tablet manufacturing: Phase transition analysis of caffeine using DSC and low frequency micro-Raman spectroscopy. Int J Pharm. 2011;420:76–83.

Mezger TG. The rheology handbook: for users of rotational and oscillatory rheometers, European Coatings Tech Files, Vincentz Network, 2014.

Thirtha V, Lehman R, Nosker T. Morphological effects on glass transition behavior in selected immiscible blends of amorphous and semicrystalline polymers. Polymer. 2006;47(15):5392–401.

Thirtha V, Lehman R, Nosker T. Glass transition phenomena in melt-processed polystyrene/polypropylene blends. Polym Eng Sci. 2005;45:1187–93.

Leblanc JL. Elastomer-filler interactions and the rheology of filled rubber compounds. J Appl Polym Sci. 2000;78(8):1541–50.

Paul DR, Robeson LM. Polymer nanotechnology: nanocomposites. Polymer. 2008;49(15):3187–204.

Qi S, Gryczke A, Belton P, Craig DQM. Characterisation of solid dispersions of paracetamol and EUDRAGIT E prepared by hot-melt extrusion using thermal, microthermal and spectroscopic analysis. Int J Pharm. 2008;354(1–2):158–67.

He F, Wang LM, Richert R. Dynamics of supercooled liquids in the vicinity of soft and hard interfaces. Phys Rev B - Condens Matter Mater Phys. 2005;71(14):1–10.

Fragiadakis D, Pissis P, Bokobza L. Glass transition and molecular dynamics in poly(dimethylsiloxane)/silica nanocom-posites. Polymer. 2005;46(16):6001–8.

Tsagaropoulos A, Eisenberg G. Dynamic mechanical study of factor a ecting the two glass transition behavior of filled polymer. Similarities and differences with random ionomers. Macromolecules. 1995;28:6067–77.

Li L, Zhou D, Huang D, Xue G. Double glass transition temperatures of poly(methyl methacrylate) confined in alumina nanotube templates. Macromolecules.

Ash BJ, Rogers D, Wiehand CJ. Mechanical Properties of Al2O3/Polymethylmethacrylate nanocomposites. Polym Compos. 2002;1014–1025.

Ash BJ, Schadler LS, Siegel RW. Glass transition behavior of alumina/polymethylmethacrylate nanocomposites. Mater Lett. 2002;55:83–7.

Lanzl T. Charakterisierung von mittels dielektrischer Spektroskopie Dissertation, Ph.D. thesis, Universitat Regensburg. 2001.

Fröhlich J, Niedermeier W, Luginsland HD. The effect of filler- filler and filler-elastomer interaction on rubber reinforcement. Compos A: Appl Sci Manuf. 2005;36(4):449–60.

Mortezaei M, Famili MHN, Kokabi M. The role of interfacial interactions on the glass-transition and viscoelastic properties of silica/polystyrene nanocomposite. Compos Sci Technol. 2011;71(8):1039–45.

Pothan LA, Oommen Z, Thomas S. Dynamic mechanical analysis of banana ber reinforced polyester composites. Compos Sci Technol. 2003;63(2):283–93.

Lee KT, Ingram A, Rowson NA. Twin screw wet granulation: the study of a continuous twin screw granulator using Positron Emission Particle Tracking (PEPT) technique. Eur J Pharm Biopharm. 2012;81(3):666–73.

Medalia AI. Effective degree of immobilization of rubber occluded within carbon black aggregates. Rubber Chem Technol. 1972;45(5):1171–94.

Thompson MR, Sun J. Wet granulation in a twin-screw extruder: implications of screw design. J Pharm Sci. 2010;99(4):2090–103.

ACKNOWLEDGMENTS AND DISCLOSURES

Financial support for this research from the Agency for Innovation by Science and Technology (IWT - Ph.D. fellowship Tinne Monteyne) and Fund for Scientific Research Flanders (FWO Flanders - Postdoc fellowship Severine Therese F.C. Mortier) are gratefully acknowledged. BASF is acknowledged for sending large amounts of caffeine and Soluplus®. Thermo Fisher Scientific (Karlsruhe) is appreciatively acknowledged for giving me the opportunity to use their rheometers in parallel for a long period of time.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monteyne, T., Heeze, L., Mortier, S.T.F.C. et al. The use of Rheology Combined with Differential Scanning Calorimetry to Elucidate the Granulation Mechanism of an Immiscible Formulation During Continuous Twin-Screw Melt Granulation. Pharm Res 33, 2481–2494 (2016). https://doi.org/10.1007/s11095-016-1973-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-016-1973-6