Abstract

Purpose

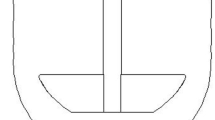

This study investigated the influence of dip rate on USP Apparatus 3 hydrodynamics in the presence of a solid dosage form (e.g. tablet) using Computational Fluid Dynamics (CFD) simulations. The primary variables of interest were the liquid phase velocity in the computational domain and wall shear stresses on the tablet surfaces.

Methods

Geometry building and model setup were based on a number of simplifying assumptions. Computational grid-independent solutions were achieved for dip rates ranging from 5 to 10 dips per minute (dpm).

Results

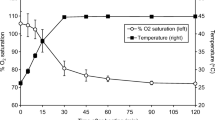

For all cases studied, the hydrodynamics exhibited a periodicity dictated by the dip rate. Cycle-to-cycle variations were found to be negligible. Higher velocities were predicted in the wake of the tablet and they peaked at midway positions both during the up- and downstrokes of the cylinder. Three sub-regions of velocity were identified inside the reciprocating cylinder. Results also showed localized vortices/recirculations specific to the up- and downstroke, in addition to local stagnation zones. The wall shear stresses and velocity magnitudes scaled proportionately with increasing dip rates while exhibiting qualitatively similar behavior in their spatial and temporal distributions.

Conclusions

Based on the predictions of the 2D axisymmetric CFD model, the hydrodynamics in USP Apparatus 3 is characterized by complex and periodic flow structures.

Similar content being viewed by others

Notes

Hereafter the terms ‘mesh screen’, ‘porous surface’ and ‘porous jump’ are used in relation to the top and/or bottom mesh screens.

Abbreviations

- C 2 :

-

Pressure jump coefficient (m−1)

- C v :

-

Total liquid volume (m3)

- d :

-

Tablet thickness (m)

- d*:

-

Dimensionless axial coordinate of a point on the tablet side surface

- h :

-

Computational domain height (m)

- h c :

-

Cylinder height (m)

- h l :

-

Liquid level with submerged tablet (m)

- N :

-

Dip rate or rate of reciprocation (dpm)

- OA:

-

Open surface area of mesh screens

- R:

-

Tablet radius (m)

- r :

-

radial position/coordinate (m)

- r*:

-

Dimensionless radial coordinate of a point on the tablet bottom and top surfaces

- Re:

-

Reynolds number

- t :

-

Physical time elapsed from start of process defined as cylinder position at the beginning of the upstroke (s)

- t*:

-

Dimensionless time defined as ratio of time t, and time required for completion of two cycles of operation

- U n :

-

Surface-normal fluid velocity (m/s)

- U z :

-

Axial velocity of moving solid parts (m/s)

- V :

-

Tablet volume (m3)

- z :

-

Axial position/coordinate (m)

- z 0 :

-

Initial axial position of a point on the bottom mesh screen (m)

- α :

-

Porous surface permeability (m2)

- Δh bottom :

-

Distance between the bottom surfaces of the cylinder and vessel (m)

- Δh top :

-

Distance between the top surfaces of the computational domain and the cylinder at the end of up stroke (m)

- Δm :

-

Porous surface thickness (m)

- ΔP :

-

Pressure drop across a porous surface (N/m2)

- μ :

-

Liquid dynamic viscosity (kg/m-s)

- ρ :

-

Liquid density (kg/m3)

- τ bot τ side , τ top :

-

Wall shear stresses on the tablet bottom, side and top surfaces respectively (N/m2)

- Φ c :

-

Cylinder diameter (m)

- Φ v :

-

Vessel diameter (m)

- ω :

-

Frequency of oscillation of moving solid parts (rad/s)

References

USP. Fourth Supplement, USP XXII–NF XVII, Drug Release <724>. Rockville, MD: USP; 1991.

USP. USP 37–NF 32, Dissolution <711>. Rockville, MD: USP; 2014.

Borst I, Ugwu S, Beckett AH. New and extended applications for USP drug release Apparatus 3. Dissolution Technologies. 1997;4:11–8.

McCarthy LG, Kosiol C, Healy AM, Bradley G, Sexton JC, Corrigan OI. Simulating the hydrodynamic conditions in the United States Pharmacopeia paddle dissolution apparatus. AAPS PharmSciTech. 2013;4:83–98.

Baxter JL, Kukura J, Muzzio FJ. Hydrodynamics-induced variability in the USP Apparatus II dissolution test. International Journal of Pharmaceutics. 2005;292:17–28.

Bai G, Armenante PM. Hydrodynamic, mass transfer and dissolution effects induced by tablet location during dissolution testing. Journal of Pharmaceutical Sciences. 2009;98:1511–31.

Kakhi M. Mathematical modeling of the fluid dynamics in the flow-through cell. International Journal of Pharmaceutics. 2009;376:22–40.

D’Arcy DM, Liu B, Bradley G, Healy AM, Corrigan OI. Hydrodynamic and species transfer simulations in the USP 4 dissolution apparatus: considerations for dissolution in low velocity pulsing flow. Pharmaceutical Research. 2010;27:246–58.

Rohrs BR, Burch-Clark DL, Witt MJ, Stelzer DJ. USP dissolution Apparatus 3 (reciprocating cylinder): instrument parameter effects on drug release from sustained release formulations. Journal of Pharmaceutical Sciences. 1995;84:922–6.

Khamanga SMM, Walker RB. The effects of buffer molarity, agitation rate, and mesh size on verapamil release from modified-release mini-tablets using USP Apparatus 3. Dissolution Technologies. 2007;14:19–23.

Yu LX, Wang JT, Hussain AS. Evaluation of USP Apparatus 3 for dissolution testing of immediate-release products. AAPS PharmSci. 2002;4:1–5.

Sanghvi PP, Nambiar JS, Shukla AJ, Collins CC. Comparison of three dissolution devices for evaluating drug release. Drug Development and Industrial Pharmacy. 1994;20:961–80.

Kakhi M. Classification of the flow regimes in the flow-through cell. European Journal of Pharmaceutical Sciences. 2009;37:531–44.

Shames IH. Mechanics of fluids. New York: McGraw-Hill Book Company; 1962.

ANSYS. ANSYS FLUENT users guide. Release 13.0. Lebanon: ANSYS; 2011.

Industrial Perforators Association. The Designers, Specifiers, and Buyers Handbook of Perforated Metals. 1993. http://iperf.org/perforating/knowledge-center/perf-handbook/pressure-loss-through-perforated-plate-air-fluid/. Accessed 2 July 2014.

Leslie Controls. Temporary Strainer Technical Information. ND. Available from: www.lesliecontrols.com/Catalogs/cataloglist.cfm, Strainers Handbook (.zip file), Temp Tech Info.pdf. Accessed 2 July 2014.

Munson BR, Young DF, Okiishi TH. Fundamentals of Fluid Mechanics. John Wiley & Sons, Inc.; 2006.

Acknowledgments and Disclosures

The authors thank Drs. Narayana Rayapati, Luke Munholand, Genong Li, and Brian Bell from ANSYS, Inc., Lebanon, NH, for their technical support in the development of models. The authors would also like to thank Drs. Stefan Schuber and James Austgen for editorial assistance.

Disclaimer

Certain software and hardware are identified in this paper to specify adequately the modeling effort involved. Such identification does not imply approval, endorsement, or certification by USP of the particular brand or product, nor does it imply that the software or hardware is necessarily the best available for the purpose or that any other brand or product was judged to be unsatisfactory or inadequate.

Author information

Authors and Affiliations

Corresponding author

Additional information

Maziar Kakhi’s Disclaimer: The views expressed in this paper are those of the authors and do not reflect the opinion nor the policy of the FDA.

Rights and permissions

About this article

Cite this article

Perivilli, S., Kakhi, M. & Stippler, E. Computational Fluid Dynamics Simulation of Hydrodynamics in USP Apparatus 3—The Influence of Dip Rate. Pharm Res 32, 1304–1315 (2015). https://doi.org/10.1007/s11095-014-1534-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-014-1534-9