Abstract

Hydrogen-rich synthesis gas was produced by pulsed dc plasma submerged into ethanol–water mixtures using an original system with a coaxial geometry. The ignition of the discharge is immediately followed by production of hydrogen and after a short time necessary for filling the outlet tubing a flame can be ignited. No auxiliary gas was used for the reforming process. The synthesis gas containing up to 60% of hydrogen was formed, at the outflow rate of 250 sccm at the average power as low as 10 W. The hydrogen production efficiency corresponds to 12 kWh/kg H2.

Similar content being viewed by others

Introduction

Rapid development of non-thermal (cold) atmospheric plasma sources since last century led to a new field of research and applications of the plasma discharges submerged into liquids. Among many applications of such systems for e.g. coatings or production of nanoparticles and nanotubes a number of recent reports has been devoted to plasma-chemical applications with main focus in the production of hydrogen [1–5]. It is interesting to note that first studies of water electrolysis and interactions of glow discharges with water solutions were described already in 1887 by Gubkin [6], followed in 1952 by Davies and Hickling [7]. The submerged arc discharges have been used already since 1930 for an underwater welding [8]. In about two last decades the growing interest in clean energy carriers have dramatically enhanced the development of different methods for production of hydrogen as an environmentally friendly alternative fuel. The utilization of gas discharge plasmas for this purpose, the submerged plasmas in particular, shows very promising results [9–12]. Plasma-based processes using ethanol with water as the source of hydrogen are of particular interest because of accessible bioethanol as a waste product. Small reactors powered by renewable electric power sources could be very useful in different applications with hydrogen-on-demand.

This paper demonstrates production of a hydrogen-rich synthesis gas H2 + CO, using an original small and low power plasma system submerged in a mixture of water with ethanol. Our systems that are predecessors of the design shown in this paper were already used for generation of the plasma discharges in liquids and were introduced in [13–18].

Experimental Arrangement

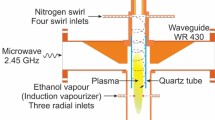

Schematic sketch of the experimental reactor is shown in Fig. 1. A coaxial diode system with a negative outer electrode terminated by a slit similar to the concept of Fused Hollow Cathodes [19] and with a central grounded anode is installed inside the 0.95 l stainless steel cylindrical reactor. The reactor is filled by 0.6 l of the mixture of deionized water and 99.5% alcohol (ethanol C2H5OH). The ethanol content in the presented experiments was 26%. The reactor chamber has two walls for the temperature control by water flowing from an external cooler/heater. The anode electrode can also serve as an inlet of an additional gas, but the experiments presented here do not use this option. The reactor is closed hermetically and its only outlet is connected to the pressure gauge, hydrogen detector (HY-Alerta), gas flow meter (glass rotameter) and an outlet nozzle for igniting the flame. When temporarily closed, the overpressure in the reactor was about 0.5 Torr (67 Pa). For detection of parameters of the liquid, the reactor is equipped by the thermometer, densitometer, pH meter and conductivity meter. Optical emission from the plasma is detected by a quartz optics connected to the PLASCALC-2000-UV–VIS-NIR Plasma Monitoring and Process Control System.

Several types of power generators were tested in the system with pure water, the 13.56 and 27.12 MHz rf generators, 2.4 GHz microwave generator, 0.1 µs pulsed dc generator and 9 ns pulsed dc generator with variable repetition frequencies, in order to select the best generation with minimum heating of the solution. In this paper, the results of the experiments performed with 9 kV, 9 ns negative pulses (rise time of 2 ns) at the repetition frequency of 15 kHz, are presented. The repetition frequency of 15 kHz was selected from preliminary experiments, in order to keep the solution temperature below 60 °C and to avoid water vapor in the produced gas. On the other hand, the repetition frequency, representing the average power, needs to provide the high efficiency of the reforming process. The root mean square value of the pulsed current delivered to the plasma from the generator was measured by oscilloscope. The content of hydrogen in the produced gas was measured continually by a HY-AlertaTM detector and measured values were checked by and compared with the gas chromatograph GC-406 (Agilent Technologies) acquired measurements of gas samples using Tedlar® Gas Sampling Bags.

Results and Discussion

The photograph of the pulsed dc discharge in the mixture of water with ethanol is shown in Fig. 2.

It was found that the production of the gas starts and stops almost instantly with the switching-on and switching-off the plasma. A short delay (about 1 min) in the hydrogen production in the graph is given by time needed for rising the pressure and displacement of the ambient air above the solution by the gaseous conversion product. The gas production was monitored by the rotameter and independently verified by igniting a stable flame at the outlet nozzle. The growing hydrogen content measured by the hydrogen detector in the produced gas as a function of the process time is shown in Fig. 3 together with corresponding values of the temperature in the electrolyte. It is seen that a high hydrogen production starts faster than the growth of temperature. The picture of the flame with 50% hydrogen content is shown as an inset in Fig. 3. The values of hydrogen volume acquired by HY-Alerta have been confirmed by independent measurements on samples transported by the Tedlar® Gas Sampling Bags to the gas chromatograph. Maximum saturated hydrogen content obtained under the experimental conditions described above was 60%. The corresponding data acquired by the gas chromatograph were 60% of H2, 22.5% of CO, 4.6% CO2 and 2.5% of methane.

The following lines and bands were observed and monitored in the optical emissions from the discharges: hydrogen atomic lines Hα (2–3 transition, λ = 656.3 nm), Hβ (2–4 transition, λ = 486.1 nm) and Hγ (2–5 transition, λ = 434 nm), atomic oxygen lines (407.7, 615.7, 777 nm triplet, 821.2, 844.6, and 926 nm) and CO Ångström system [(0,2), λ = 519.8 nm]. The OH bands were not observed in the spectra with ethanol. However, it should be noted that OH bands were observed in the discharge in pure water.

The dissociation of water molecules in the discharge is the main production of hydrogen atoms according to the reaction

Note that Eq. (1) represents an intensively studied process of plasma-assisted electrolysis as a more efficient alternative to the conventional electrolysis [2, 20]. Both H and OH radicals from the water molecule can react with ethanol—the reaction with hydrogen atom, i.e. forming molecular hydrogen stimulated by presence of water

and reaction

They can be followed by

and

forming acetaldehyde CH3CHO [21]. Reactions and electron-molecular reactions of ethylgroup C2H5 and acetaldehyde CH3CHO lead to forming of methylene CH2, ethylene C2H4, methyl group CH3, acetyl group CH3CO, and methane CH4. These compounds can enter reactions forming again CH3, vinyl radical C2H3, aldehyde group HCO, CH2, OH, H2, radical CH, H, CH4, ethane C2H6, CO, O and subsequently acetylene C2H2, C2H4, CH4, CO, CO2, OH, H, HCO and O [21]. Some of the products enter the reactions again and some are seen at the output of the reactor, i.e. H2, CO, CO2 and CH4. There can be low amounts of C2H4 and C2H6 in the output gas as reported e.g. in [22], but they were not recorded by the gas chromatography. CO and radicals H and O are seen in the plasma by means of Optical Emission Spectroscopy (OES).

Optical emission spectra from the process for two repetition frequencies of the pulses, 12 and 15 kHz, are shown in Fig. 4. Both spectra have a similar character. The higher the repetition frequency, the higher the average power delivered to the process. The ratio of emissions of two hydrogen lines (here from 2–4 to 2–3 transitions) in a non-equilibrium plasma depends exponentially on the electron temperature [23]. Thus, the different emission intensity ratios Hβ/Hα, 0.081 for 12 kHz and 0.090 for 15 kHz, respectively, reflect the increase of the electron temperature in the plasma with power. Besides strong hydrogen lines the spectra feature CO Ångström system (0,2) band, weak hydrogen molecular band and intense atomic oxygen lines.

We believe that the reason why the OH radical has not been observed in the optical emission spectra is its consumption by reactions with the C2H5O radical, according to Eq. (3.) and/or dissociation into O and H atoms following

Conductivity and density measurements of the electrolyte along the longer set of conversion experiments are shown in Fig. 5. The conductivity of the mixture of water with ethanol is monotonically increasing with the time from an initial value of 1 µS/cm, which corresponds to deionized water mixed with non-conductive pure ethanol. At the same time the density of the mixture decreases, which indicates decreasing concentration of the ethanol in water. This result indicates that for stable production of hydrogen in the reactor the content of ethanol should be continuously measured and compensated to the initial level. The pH values change with the time, too. Within 1 h after the switching-on the plasma the pH value decreases from 5.7 (fresh mixture) to 4.74.

Hydrogen Production Efficiency

There is a number of reports on different methods for the hydrogen production. The comparison of these methods is not simple as they represent different production volumes, different types of process powers, different conversion rates of reagents and different power efficiencies of used generators. Moreover, different authors may also use different units. In a rough approximation it is possible to compare individual methods by their power consumption for unit weight of the molecular hydrogen gas. Table 1 compares the approximate numbers calculated from data published for several methods.

Conclusion

It has been found that the nanosecond pulsed submerged plasma induces chemical reactions already at very low power with reasonably low heat losses. The plasma reforming of C2H5OH in water produces up to 60% hydrogen content in the resulting synthesis gas. The ignition of the discharge is followed by an instant start of the gas production, as well as the switching-off the power stops the gas production. Experiments indicate very low values of the energy consumption, about 12 kWh/kg hydrogen using short dc pulses with average power as low as 10 W. Moreover, the relevant production of the syngas at these conditions is up to 250 sccm. Keeping the temperature in ethanol mixtures with water roughly below 60 °C was found important to avoid vapor content in the produced gas. This is because of the lower boiling point of ethanol (about 78 °C) than that of water. Close to the ethanol boiling point the total flow rate of the produced gas can raise up to over 1500 sccm.

Obtained results confirm feasibility of using small size low power reactors as the compact bio-ethanol reformers producing hydrogen “on-demand”. These reactors could have a number of applications and they can be powered also from simple renewable energy generators.

References

Zhang Y-P, Li Y, Wang Y, Liu Ch-J, Eliasson B (2003) Plasma methane conversion in the presence of carbon dioxide using dielectric-barrier discharges. Fuel Process Technol 83:101–109

Mizuno T, Akimoto T, Azumi K, Ohmori T, Aoki Y, Takahashi A (2005) Hydrogen evolution by plasma electrolysis in aqueous solution. Jpn J Appl Phys 44(1A):396–401

Wang Q, Shi H, Yan B, Jin Y, Cheng Y (2011) Steam enhanced carbon dioxide reforming of methane in DBD plasma reactor. Int J Hydrog Energy 36(14):8301–8306

Li D, Li X, Bai M, Tao X, Shang S, Dai X, Yin Y (2009) CO2 reforming of CH4 by atmospheric pressure glow discharge plasma: a high conversion ability. Int J Hydrogen Energy 34:308–313. doi:10.1016/j.ijhydene.2008.10.053

Kalamaras CM, Efstathiou AM (2013) Hydrogen production technologies: current state and future developments. Hindawi Publishing Corporation, Conference Papers in Energy, vol 2013, Article ID 690627. doi:10.1155/2013/690627

Gubkin J (1887) Elektrolytische Metallabscheidung an der freien Oberfläche einer Salzlösung. Ann Phys 268(9):114–115

Davies RA, Hickling A (1952) Glow-discharge electrolysis. Part I. The anodic formation of hydrogen peroxide in inert electrolytes. J Chem Soc. doi:10.1039/JR9520003595

LeHardy P, Elliott K (2010) Underwater welding and non-destructive testing in support of US Navy Ship Repair Operations. Presentation of Phoenix International for Underwater Solutions Worldwide. https://www.navalengineers.org/SiteCollectionDocuments/2010%20Proceedings%20Documents/FMMS%202010/Presentations/LeHardy.pdf

Chaffin JH, Bobbio SM, Inyang HI, Kaanagbara L (2006) Hydrogen production by plasma electrolysis. J Energy Eng 132:104–108. doi:10.1061/(ASCE)0733-9402

Yan Z, Chen L, Wang H (2006) Experimental study of plasma under-liquid electrolysis in hydrogen generation. Chin J Proc Eng 6(3):396–401

Yan Z, Chen L, Wang H (2008) Hydrogen generation by glow discharge plasma electrolysis of ethanol solutions. J Phys D Appl Phys 41:155205 (p 7)

Czylkowski D, Hrycak B, Miotk R, Jasinski M, Dors M, Mizeraczyk J (2015) Hydrogen production by conversion of ethanol using atmospheric pressure microwave plasmas. Int J Hydrogen Energy 40:14039–14044. doi:10.1016/j.ijhydene.2015.06.101

Baránková H, Bárdos L (2009) Atmospheric pressure plasma sources and processing. In: Martin PM (ed) Handbook of deposition technologies for films and coatings, 3rd edn. Elsevier, William Andrew, Oxford

Baránková H, Bárdos L (2012) Cold atmospheric plasma in liquids. AVS 59th Int. Symposium and Exhibition, October 28–November 2, 2012, Tampa, FL, paper SE + PS-TuA4

Baránková H, Bárdos L (2012) Cold atmospheric plasma inside water. Int. Conf. Metal. Coat. & Thin Films-ICMCTF-2012, San Diego CA, April 23–27 2012, paper G3–1–2

Bárdos L, Baránková H (2013) Cold atmospheric plasma assisted production of hydrogen. AVS 60th Int. Symposium & Exhibition, October 27–November 1, 2013, Long Beach CA, paper SE + PS-ThM10

Baránková H, Bárdos L (2014) Plasma reforming of ethanol. Int. Conf. Metal. Coat. & Thin Films - ICMCTF-2014, San Diego CA, April 28–May 2, 2014, paper TS6-7

Bárdos L, Baránková H (2015) Atmospheric plasma in liquids. AVS 62nd Int. Symposium & exhibition, October 18–23, 2015, San Jose CA, paper SE + PS + SM-TuM5 Invited

Baránková H, Bárdos L (2002) Fused hollow cathode cold atmospheric plasma source for gas treatment. Catal Today 72:237–241

Kanarev Ph M, Mizuno T (2003) Cold fusion by plasma electrolysis of water. new energy technologies ISSN 1684-9698, 1(10): 5–10. http://www.free-energy-info.co.uk/Issue10.pdf

Levko D, Shchedrin A, Chernyak V, Olszewski S, Nedybaliuk O (2011) Plasma kinetics in ethanol/water/air mixture in a “tornado”—type electrical discharge. J Phys D Appl Phys 44:145206 (13 pp)

Yanguas-Gil A, Hueso JL, Cotrino J, Cabalerro A, González-Elipe AR (2004) Reforming of ethanol in a microwave surface-wave plasma discharge. Appl Phys Lett 85:4004–4006

Park Ch (1971) Hydrogen line ratios as electron temperature indicators in nonequilibrium plasmas. J Quant Spectrosc Radiat Transfer 12:323–370

Milbrandy A, Mann M (2009) Technical Report NREL/TP-560-42773. http://www.nrel.gov/docs/fy09osti/42773.pdf

Haryanto A, Fernando S, Murali N, Adhikari S (2005) Current status of hydrogen production techniques by steam reforming of ethanol: a review. Energy Fuels 19(5):2098–2116

Du C, Li H, Zhang L, Wang J, Huang D, Xiao M, Cai J, Chen Y, Yan H, Ya Xiong, Yi Xiong (2012) Hydrogen production by steam-oxidative reforming of bio-ethanol assisted by Laval nozzle arc discharge. Int J Hydrogen Energy 37:8318–8329

Cormier JM, Rusu I (2001) Syngas production via methane steam reforming with oxygen: plasma reactors versus chemical reactors. J Phys D Appl Phys 34:2798–2803

Heintze M, Pietruszka B (2004) Plasma catalytic conversion of methane into syngas: the combined effect of discharge activation and catalysis. Catal Today 89:21–25

Petitpas G, Gonzalez-Aguilar J, Darmon A, Fulcheri L (2010) Ethanol and E85 reforming assisted by a non-thermal arc discharge. Energy Fuels 24:2607–2613

Jasinski M, Czylkowski D, Hrycak B, Dors M, Mizeraczyk J (2013) Atmospheric pressure microwave plasma source for hydrogen production. Int J Hydrogen Energy 38:308–313

Acknowledgements

Financial support by the J. Gust. Richert Foundation in Sweden and by the European Institute of Innovation and Technology, under the KIC InnoEnergy SynCon project is gratefully acknowledged. The authors are grateful to dr. M. Oestberg from Haldor Topsoe A/S in Lyngby, Denmark for help with GC measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Bardos, L., Baránková, H. & Bardos, A. Production of Hydrogen-Rich Synthesis Gas by Pulsed Atmospheric Plasma Submerged in Mixture of Water with Ethanol. Plasma Chem Plasma Process 37, 115–123 (2017). https://doi.org/10.1007/s11090-016-9766-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-016-9766-6