Abstract

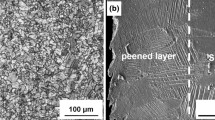

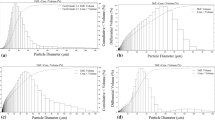

Formation of the FeAl3 or Fe2Al5 phase during the aluminization of iron-based alloys causes detrimental behaviour of the material due to the brittleness of these phases and the different coefficient of thermal expansion between the base material and the resulting diffusion coating. In order to control the microstructure of the produced diffusion zone and its evolution, two different slurry thicknesses (30–50 and 100–150 µm) using high-purity aluminium spherical particles and three different heat treatments times (5, 10 and 20 h) were tested over ferritic–martensitic P92 steel. After the heat treatment, iron–aluminide phases rich in aluminium content were formed. After 1350 hours of exposure in air at 650 °C, it was found that for the coatings in the range of 30–50 µm neither FeAl3 nor Fe2Al5 phase remained in the diffusion coating, while Fe2Al5 did remain in those coatings in the range of 100–150 µm.

Similar content being viewed by others

References

A. Agüero, R. Muelas, M. Gutierrez, R. Van Vulpen, S. Osgerby and J. P. Banks, Surface and Coatings Technology 201, 6253 (2007).

R. Roussel, V. Kolarik, M. Juez Lorenzo and H. Fietzek, Oxidation of Metals 81, 179 (2014).

V. Kolarik, R. Roussel, M. Juez Lorenzo and H. Fietzek, Materials at High Temperatures 29, 89 (2012).

A. Agüero, Revista de Metalurgia 43, 63 (2007).

F. Pedraza, M. Mollard, B. Ranou, J. Balmain, B. Bouchaud and G. Bonnet, Materials Chemistry and Physics 134, 700 (2012).

X. Montero, M. Galetz and M. Schütze, Surface and Coatings Technology 206, 1586 (2011).

B. Bouchaud, B. Rannou and F. Pedraza, Materials Chemistry and Physics 143, 416 (2013).

A. Agüero, V. González, M. Gutiérrez, R. Knödler, R. Muelas and S. Straub, Materials and Corrosion 62, 561 (2011).

A. Agüero, M. García and M. Gutiérrez, Materials and Corrosion 56, 937 (2005).

A. Agüero, R. Muelas, A. Pastor and S. Osgerby, Surface and Coatings Technology 200, 1219 (2005).

A. Agüero, V. González, P. Mayr and K. Spiradek-Hahn, Materials Chemistry and Physics 141, 432 (2013).

B. A. Pint, Y. Zhang, L. R. Walker and I. G. Wright, Surface and Coatings Technology 202, 637 (2007).

A. Fry, S. Osgerby and M. Wright, Oxidation of Alloys in Steam. Report No. NPL Report MATC(A)90 (2002).

B. L. Bates, Y. Q. Wang, Y. Zhang and B. A. Pint, Surface and Coatings Technology 204, 766 (2009).

S. Dryepondt, Y. Zhang and B. A. Pint, Surface and Coatings Technologie 201, 3880 (2006).

S. Velraj, Y. Zhang, E. W. Hawkins and B. A. Pint, Materials and Corrosion 63, 909 (2012).

K. Nishida and T. Narita, Japan Inst. Metals 35, 269 (1971).

V. I. Dybkov, Journal of Materials Science 25, 3615 (1990).

Y. Tanaka and M. Kajihara, Journal of Materials Science 45, 5676 (2010).

Y. Tanaka and M. Kajihara, Materials Transactions 50, 2212 (2009).

G. Temizel and M. Özenbaş, Turkish Journal of Engineering and Environmental Sciences 31, 71 (2007).

H. R. Shahverdi, M. R. Ghomashchi, S. Shabestari and J. Hejaci, Journal of Materials Processing Technology 124, 345 (2002).

W.-J. Cheng and C.-J. Wang, Surface and Coatings Technology 204, 824 (2009).

V. Rohr, M. Schütze, E. Fortuna, D. N. Tsipas, A. Milewska and F. J. Pérez, Materials and Corrosion 56, 874 (2005).

B. A. Pint, Y. Zhang, P. F. Tortorelli, J. A. Haynes and I. G. Wright, Materials at High Temperatures 18, 1 (2001).

Y. Zhang, A. P. Liu and B. A. Pint, Materials and Corrosion 58, 751 (2007).

S. Kobayashi and T. Yakou, Materials Science and Engineering A 338, 44 (2002).

M. V. Akdeniz and A. O. Mekhrabov, Acta mater. 46, 1185 (1998).

A. O. Mekhrabov and M. V. Akdeniz, Acta Materials 47, 2067 (1999).

H. J. Grabke, Intermetallics 7, 1153 (1999).

X. Montero, M. C. Galetz and M. Schütze, Surface and Coatings Technologie 236, 465 (2013).

J. T. Bauer, X. Montero, M. Schütze, and M. C. Galetz, Surface and Coatings Technologie 285, 179 (2016).

R. Roussel, Research on multifunctional high temperature coatings based on micro sized aluminium particles. PhD Thesis, Universidad Complutense de Madrid, Fraunhofer ICT, 2013.

M. C. Galetz, X. Montero, M. Mollard, M. Günthner, F. Pedraza and M. Schütze, Intermetallics 44, 8 (2014).

K. Murakami, N. Nishida, K. Osamura, Y. Tomota and T. Suzuki, Acta Materialia 52, 2173 (2004).

http://www.crct.polymtl.ca/fact/ Accesed March 2016.

L. Levin, A. Ginzburg, L. Klinger, T. Werber, A. Katsman and P. Schaaf, Surface and Coatings Technologie 106, 209 (1998).

E. G. Ivanov and N. E. Zhukov, translated from Metallovedenie I Termisheskaya Obrabotka Metallov, No. 6 (1979), pp. 33–35.

Y. Zhang, B. A. Pint, K. M. Cooley and J. A. Haynes, Surface and Coatings Technology 200, 1231 (2005).

B. A. Pint and Y. Zhang, Materials and Corrosion 62, 549 (2011).

I. O. Golosnoy, A. Cipitria and T. W. Clyne, Journal of Thermal Spray Technology 18, 809 (2009).

Acknowledgements

The research leading to these results has received funding from the European Union’s Seventh Framework Programme (FP7/2007-2013) under Grant Agreement No NMP3-SL-2012-310436 POEMA.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bermejo Sanz, J., Roussel García, R., Kolarik, V. et al. Influence of the Slurry Thickness and Heat Treatment Parameters on the Formation of Aluminium Diffusion Coating. Oxid Met 88, 179–190 (2017). https://doi.org/10.1007/s11085-017-9771-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-017-9771-z