Abstract

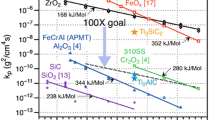

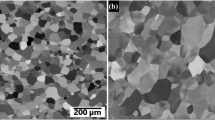

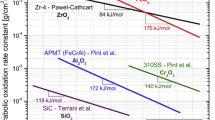

New nuclear fuel cladding materials are being evaluated that can withstand steam environments ≥1200 °C for short (≤4 h) periods in case of a beyond design basis accident. This study focused on commercial and model Fe–Cr alloys, where there is considerable experience in fabricating and joining. Exposures in 1 bar steam and air for 4 h at 800–1300 °C showed that the commercial Fe–Cr alloys were very sensitive to composition and only Fe-25.8%Cr-1%Mo formed a protective chromia scale at 1200 and 1300 °C in steam. A model Fe-22.5%Cr + Mn,Si,Y alloy also formed a protective scale at 1200 °C in steam. Analytical transmission electron microscopy of the reaction products revealed that (1) nominally equiaxed Cr2O3 formed at 1000–1200 °C; (2) at 1000 °C, there was a Mn inner and outer layer but at 1100 and 1200 °C only an outer layer was observed; (3) an amorphous SiO2 inner layer was observed at 1000 and 1100 °C, but the SiO2 was crystalline on the 22.5%Cr model alloy at 1200 °C, which was confirmed by electron and X-ray diffraction; and (4) Fe was found throughout the Cr2O3 formed on alloys without Mn at 1200 °C in steam and air, Fe-rich oxide near the gas interface and Fe-rich metal precipitates near the metal–oxide interface. A few Fe-rich precipitates were detected in oxides formed at 1100 °C and none at 1000 °C. The incorporation of Fe and crystallization of SiO2 at 1200 °C may be detrimental to the formation of a protective chromia scale in steam at ≥1200 °C for this application and explain why such high Cr contents are needed for protective behavior.

Similar content being viewed by others

References

K. R. Robb, M. W. Francis, and L. J. Ott, Nuclear Technology 186, 145 (2014).

L. Hallstadius, S. Johnson, and E. Lahoda, Progress in Nuclear Energy 57, 71 (2012).

S. J. Zinkle, K. A. Terrani, J. C. Gehin, L. J. Ott, and L. L. Snead, Journal of Nuclear Materials 448, 374 (2014).

L. J. Ott, K. R. Robb, and D. Wang, Journal of Nuclear Materials 75, 520 (2014).

K. A. Terrani, S. J. Zinkle, and L. L. Snead, Journal of Nuclear Materials 448, 420 (2014).

B. A. Pint, K. A. Terrani, Y. Yamamoto, and L. L. Snead, Metallurgical and Materials Transactions E 2, 190 (2015).

T. Cheng, J. R. Keiser, M. P. Brady, K. A. Terrani, and B. A. Pint, Journal of Nuclear Materials 427, 396 (2012).

B. A. Pint, K. A. Terrani, M. P. Brady, T. Cheng, and J. R. Keiser, Journal of Nuclear Materials 440, 420 (2013).

B. A. Pint, K. A. Terrani, J. R. Keiser, M. P. Brady, Y. Yamamoto, and L. L. Snead, NACE Paper ED2013-3083, Houston, TX, presented at the 16th Environmental Degradation conference, (Asheville, NC, 2013).

K. A. Terrani, B. A. Pint, C. M. Parish, C. M. Silva, L. L. Snead, and Y. Katoh, Journal of the American Ceramic Society 97, 2331 (2014).

B. A. Pint, K. A. Unocic, and K. A. Terrani, Materials at High Temperature 32, 28 (2015).

Y. Yamamoto, B. A. Pint, K. A. Terrani, K. G. Field, Y. Yang, and L. L. Snead, J. Nuclear Materials 467, 703 (2015).

C. T. Fujii and R. A. Meussner, Journal of the Electrochemical Society 111, 1215 (1964).

J. M. Francis and W. H. Whitlow, Corrosion Science 5, 701 (1965).

C. S. Tedmon, Journal of the Electrochemical Society 113, 766 (1966).

G. C. Wood and J. Boustead, Corrosion Science 8, 719 (1968).

G. C. Wood, I. G. Wright, T. Hodgkiess, and D. P. Whittle, Materials and Corrosion 21, 900 (1970).

I. G. Wright and B. A. Wilcox, Oxidation of Metals 8, 283 (1974).

D. Caplan and G. I. Sproule, Oxidation of Metals 9, 459 (1975).

H. Nagai, Materials Science Forum 43, 75 (1989).

J. Shen, L. Zhou, and T. Li, Oxidation of Metals 48, 347 (1997).

R. Peraldi and B. A. Pint, Oxidation of Metals 61, 463 (2004).

B. A. Pint and I. G. Wright, Oxidation of Metals 63, 193 (2005).

E. Essuman, G. H. Meier, J. Zurek, M. Hänsel, L. Singheiser, and W. J. Quadakkers, Scripta Materialia 57, 845 (2007).

W. J. Quadakkers, J. Żurek, and M. Hänsel, JOM Journal of the Minerals Metals and Materials Society 61(7), 44 (2009).

N. Mu, K. Y. Jung, N. M. Yanar, G. H. Meier, F. S. Pettit, and G. R. Holcomb, Oxidation of Metals 78, 221 (2012).

T. Gheno, D. Monceau, and D. J. Young, Corrosion Science 64, 222 (2012).

B. A. Pint, B. L. Armstrong, I. G. Wright, M. P. Brady, P. F. Tortorelli, R. R. Judkins, and T. R. Armstrong, patent application 12/119,648, submitted 2008, U.S. patent application 2009/0286107, Nov. 19, 2009.

W. J. Quadakkers, J. Piron-Abellan, V. Shemet, and L. Singheiser, Materials at High Temperature 20, 115 (2003).

B. A. Pint, Oxidation of Metals 45, 1–37 (1996).

B. A. Pint, A. J. Garratt-Reed, and L. W. Hobbs, Journal of the American Ceramic Society 81, 305 (1998).

C. M. Cotell, G. J. Yurek, R. J. Hussey, D. F. Mitchell, and M. J. Graham, Oxidation of Metals 34, 173–200 (1990).

T. Denys and P. M. Gielen, Metallurgical Transactions 2, 1423 (1971).

P. J. Grobner, Metallurgical Transactions 4, 251 (1973).

F. Danoix and P. Auger, Materials Characterization 44, 177 (2000).

G. Bonny, D. Terentyev, and L. Malerba, Journal of phase equilibria and diffusion 31, 439 (2010).

M. H. Mathon, Y. de Carlan, G. Geoffroy, X. Averty, A. Alamo, and C. H. de Novion, Journal of Nuclear Materials 312, 236 (2003).

K. G. Field, X. Hu, K. Littrell, Y. Yamamoto, and L. L. Snead, Journal of Nuclear Materials 465, 746 (2015).

Acknowledgements

The experimental work was conducted by M. Howell, M. Stephens, T. Lowe, D. Coffey, T. Jordan and E. Cakmak. S. Dryepondt and K. Terrani provided useful comments on the manuscript. This research was funded by the U.S. Department of Energy’s Office of Nuclear Energy, Advanced Fuel Campaign of the Fuel Cycle R&D program. The FEI Talos F200X STEM was used as part of the Nuclear Science User Facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pint, B.A., Unocic, K.A. Steam Oxidation Evaluation of Fe–Cr Alloys for Accident Tolerant Nuclear Fuel Cladding. Oxid Met 87, 515–526 (2017). https://doi.org/10.1007/s11085-017-9754-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-017-9754-0