Abstract

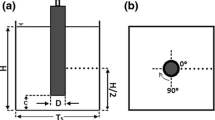

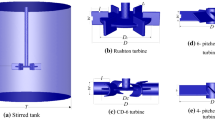

The objective of this paper is to characterize the hydrodynamic and thermal behaviors of yield stress fluids within a cylindrical agitated vessel equipped with simple helical ribbon stirrers (SHR) (one and two-stages) by means of the numerical simulation approach. For this purpose, a computational fluid dynamic simulation using the 3D finite volume technique has been carried out to solve the continuity, momentum and thermal energy equations. In this study, we have analyzed the Oldroyd and Reynolds numbers effects on the hydrodynamic and thermal behaviors for the two mentioned stirrers types. In addition, the influence of the impeller width and its clearance from the vessel wall on the velocity and thermal fields has been investigated. Velocity and thermal fields’ visualization has been presented in different (r–z) and (r–θ) planes. Moreover, the power constant and Nusselt number are correlated by a relationship relating the physical properties and the geometric ratios defining the SHR.

Similar content being viewed by others

Abbreviations

- \({\text{a}} = \frac{{\uplambda }}{{{\uprho{\text{ C}}}_{\text{p}} }}\) :

-

Thermal diffusivity (m s−2)

- C = (D − da)/D:

-

Dimensionless clearance

- \({\text{C}}_{\text{p}}\) :

-

Specific heat capacity (J Kg−1 K−1)

- D:

-

Vessel diameter (m)

- da :

-

Impeller diameter (m)

- dr :

-

Rotor diameter (m)

- g:

-

Acceleration of gravity (m s−2)

- H:

-

Liquid height in the tank (m)

- h:

-

Heat transfer coefficient (W/m2K)

- hi :

-

Impeller height (m)

- µ:

-

Viscosity of Bingham fluid (Pa s)

- µa :

-

Apparent viscosity (Pa s)

- N:

-

Rotation speed of the agitator (tr/s)

- Nr :

-

Number of impeller ribbon

- \({\text{R}} = \frac{{{\text{d}}_{\text{a}} }}{2}\) :

-

Impeller radius (m)

- P1 :

-

Pressure (Pa)

- Pw :

-

Power (w)

- p:

-

Pitch of the ribbon (m)

- ts :

-

Time (s)

- \({\text{V}}_{\text{c}} = 2{\uppi{\text{ NR}}}\) :

-

Characteristic velocity (m s−1)

- \({\text{V}}^{\prime}\) :

-

Vessel volume

- w:

-

Ribbon width (m)

- \({\bar{\uptheta }}\) :

-

Average temperature (K)

- \({\uptheta }_{\text{i}}\) :

-

Initial internal temperature (K)

- \({\uptheta }_{\text{w}}\) :

-

The vessel wall temperature (K)

- \({\uptau }\) :

-

Shear stress (Pa)

- τ0 :

-

Yield stress (Pa)

- \({\dot{\upgamma }}\) :

-

Flow shear rate (s−1)

- λ:

-

Thermal conductivity (W/mK)

- ρ:

-

Fluid density (Kg m−3)

- A = Po * Re:

-

Power constant

- \({\text{dv}} = {\text{rdrd}}\uptheta {\text{dz}}\) :

-

Element volume

- \({\text{F}}_{\text{o}} = \frac{2}{{{\uppi {\text{Pe}}}}}{\text{t}}\left( {\frac{{{\text{d}}_{\text{a}} }}{\text{D}}} \right)^{2}\) :

-

Fourier number

- \({\text{Fr}} = \frac{{ 2\left( {{\uppi {\text{N}}}} \right)^{2} {\text{D}}}}{\text{g}}\) :

-

Froude number

- G:

-

Viscous dissipation function

- m:

-

Regularization parameter

- \({\text{Nu}} = \frac{\text{hD}}{{\uplambda }}\) :

-

Nusselt number

- \({\text{Od}} = \frac{{{\uptau }_{0} {\text{D}}}}{{2 {\upmu {\text{V}}}_{\text{c}} }}\) :

-

Oldroyd number

- \({\text{Pe}} = {\text{RePr}} = \frac{{{\text{Nd}}_{\text{a}}^{2} }}{\text{a}}\) :

-

Peclet number

- \({\text{P}}_{\text{o}} = \frac{{{\text{P}}_{\text{w}} }}{{{\uprho \text{N}}^{3} ({\text{d}}_{\text{a}} )^{5} }}\) :

-

Power number

- \({ \Pr } = \frac{{{{\upmu \text{C}}}_{\text{p}} }}{{\uplambda }}\) :

-

Prandtl number

- \({\text{P}}_{\text{re}} = \frac{{{\text{P}}_{1} }}{{{{\uprho }}\left( {{{\uppi \text{ND}}}} \right)^{2} }}\) :

-

Dimensionless pressure

- (r, \({\uptheta }\), z):

-

Dimensionless co-ordinates (dimensional coordinates divided by D/2)

- \({\text{Re}} = \frac{{{{\uprho N d}}_{\text{a}} ^{2} }}{\upmu }\) :

-

Reynolds number

- \({\bar{\text{T}}} = \frac{{{\bar{\uptheta }} - {\uptheta }_{\text{i}} }}{{{\uptheta }_{\text{w}} - {\uptheta }_{\text{i}} }}\) :

-

Average dimensionless temperature

- \({\text{t}} = 2{\uppi \text{Nt}}_{\text{s}}\) :

-

Dimensionless time

- \({\text{V}}_{\text{i}}\) :

-

Viscosity correction factor

- \({\vec{\text{V}}}({\text{U}}, {\text{V}}, {\text{W}})\) :

-

Dimensionless velocity vector (dimensional velocity divided by \(2{\uppi{\text{ NR}}}\))

- \({\upeta }_{\text{a}} = \frac{{\upmu }_{\text{a}}}{\upmu }\) :

-

Dimensionless apparent viscosity

References

Scott Fogler H, Nihat Gurmen M (2008) Elements of chemical reaction engineering. University of Michigan, Michigan

Delaplace G, Leuliet JC, Relandeau V (2000) Circulation and mixing times for helical ribbon impellers. Rev Exp Fluids 28:170–182

Guerin P, Carreau PJ, Patterson WI, Paris J (1984) Characterization of helical impellers by circulation times. Can J Chem Eng 62:3

Takahashi K, Iwaki M, Yokota T, Konno H (1989) Circulation time for pseudo-plastic liquids in a vessel equipped with a variety of helical ribbon impellers. J Chem Eng Jpn 22:413–418

Curran SJ, Hayes RE, Afacan A, Williams M, Tanguy P (2000) Experimental mixing of a yield stress fluid in a laminar stirred tank. Ind Eng Chem Res 39:195–202

Szulc K (2013) Optimization of geometry of helical ribbon impeller operating in the laminar flow of the liquid. Prosimy cytować jako: Inż Ap Chem 52(3):255–258

Yao W, Mishima M, Takahashi K (2001) Numerical investigation on dispersive mixing characteristics of MAXBLEND and double helical ribbons. J Chem Eng 84:565–571

Minge Z, Lühong Z, Bin J, Yuguo Y, Xingang L (2008) Calculation of Metzner constant for double helical ribbon impeller by computational fluid dynamic method. Chin J Chem Eng 16(5):686–692

Wang JJ, Feng LF, Gu XP, Wang K, Hu CH (2000) Power consumption of inner-outer helical ribbon impellers in viscous Newtonian and non-Newtonian fluids. J Chem Eng Sci 55:2339–2342

Zhu XL, Song QA, Xu BQ, Wang K (1984) Mixing characteristics of impellers for the mixing of highly viscous non-Newtonian fluids. China Synthet Rubber Ind 7(4):255–258 (in Chinese)

Robinson M, Cleary PW (2012) Flow and mixing performance in helical ribbon mixers. J Chem Eng Sci 84:382–398

Kuncewicz Cz, Rieger F, Pietrzykowski M, Stelmach J (2013) 3D/2D hybrid model for ribbon impellers operating in laminar regime. J Chem Eng Proc 73:50–58

Kuncewicz Cz, Pietrzykowski M (2010) A 3D/2D hybrid model for flat blade impellers operating in the laminar flow. J Chem Proc Eng 3(1):289–302

Kuncewicz Cz, Pietrzykowski M (2010) Verification of a 3D/2D hybrid model for laminar mixing range. J Chem Proc Eng 31:303–315

Slemenik Perše L, Zumer M (2004) Mixing and viscosity determinations with helical ribbon impeller. Chem Biochem Eng Q 18(4):363–371

Coyle CK, Hirschland HE, Michel BJ, Oldschue JY (1970) Heat transfer to jackets with close clearance impellers in viscous materials. Can J Chem Eng 48:275

Shamlou PA, Edwards MF (1986) Heat transfer to viscous Newtonian and non-Newtonian fluids for helical ribbon mixers. J Chem Eng Sci 41(8):1957–1967

Nagata S (1975) Mixing principles and applications. Wiley, New York

Carreau PJ, Patterson I, Yap CY (1976) Mixing of viscoelastic fluids with helical- ribbon agitators. I-Mixing time and flow patterns. Can J Chem Eng 54:3

Ishibashi K, Yamanaka A, Mitsuishi N (1979) Heat transfer in agitated vessels with special types of impellers. J Chem Eng Jpn 12(2):230–235

Bourne JR, Butler H (1969) Power consumption of helical ribbon impellers in viscous liquids. Trans Inst Chem Eng 47:263–270

Soliman MG (1985) Agitation de fluides visqueux pseudo-plastiques par un double ruban hélicoïdal. Thèse de docteur ingénieur de l’Institut National Polytechnique de Toulouse

Niedzielska A, Kuncewicz Cz (2005) Heat transfer and power consumption for ribbon impellers. Mixing efficiency. J Chem Eng Sci 60:2439–2448

Anne-Archard D, Marouche M, Boisson HC (2006) Hydrodynamics and Metzner–Otto correlation in stirred vessels for yield stress fluids. Chem Eng J 125:15–24

Metzner AB, Otto RE (1957) Agitation of non-Newtonian fluids. AIChE J 3(1):3–10

Ameur H, Bouzit M, Ghenaim A (2013) Hydrodynamics in a vessel stirred by simple and double helical ribbon impellers. Cent Eur J Eng 3(1):87–98

Ameur H, Bouzit M (2013) Power consumption for stirring shear thinning fluids by two-blade impeller. Energy J 50:326–332

Bingham EC (1922) Fluidity and plasticity. McGraw-Hill Book Company Inc, New York

Baccar M, Mseddi M, Abid MS (2001) Contribution numérique à l’étude hydrodynamique et thermique des écoulements turbulents induits par une turbine radiale en cuve agitée. Int J Therm Sci 40:753–772

Harlow FH, Welch JE (1965) Numerical calculation of time-dependant viscous incompressible flow of fluids with free surface. Phys Fluids 8(12):2182

Douglas J, Gunn JE (1964) A general formulation of alternating direction implicit methods. Num Math 6:428–453

Chorin AJ (1968) Numerical solution of the Navier–Stokes equations. Math Comp 22:745–762

Braza M (1981) Simulation numérique du décollement instationnaire externe par une formulation vitesse-pression. Application à l’écoulement autour d’un cylindre. Thèse de Docteur Ingenieur. Institut National Polytechnique de Toulouse

Ayadi A (2011) Exact analytic solutions of the lubrication equations for squeeze-flow of a biviscous fluid between two parallel disks. J Non-Newton Fluid Mech 166:1253–1261

Tanner RI, Milthorpe JF (1983) Simulation of the flow of fluids with yield stress. Num Meth Lam Turb Flow. In: Taylor C, Johnson JA, Smith WR (eds) Proceedings of 3rd international conference on Seattle, Pineridge Press, Swansea, pp 680–690

Papanastasiou TC (1987) Flow of materials with yield. J Rheol 31:385–404

Bertrand F, Tanguy PA, Brito de la Fuente E, Carreau P (1999) Numerical modeling of the mixing flow of second-order fluids with helical ribbon impellers. J Comput Methods Appl Mech Eng 180(15):267–280

Kappel M (1979) Development and application of a method for measuring the mixture quality of miscible liquids. III. Application of the new method for highly viscous Newtonian liquids. Int Chem Eng J 19:571–590

Kuncewicz Cz, Pietrzykowski M, Szulc K (2001) Modelowanie hydrodynamiki mieszalnika dla mieszadeł wst egowych pracujacych w ruchu laminarnym. Inżynieria Chemiczna i Procesowa 22:461–481

Von Mises R (1913) Mechanik der festen Körper im plastisch deformablen Zustand. Göttin Nachr Math Phys 1:582–592

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gammoudi, A., Ayadi, A. & Baccar, M. The hydrodynamic and thermal characterization of a yield stress fluid in stirred tanks equipped with simple helical ribbons with two stages. Meccanica 52, 1743–1766 (2017). https://doi.org/10.1007/s11012-016-0506-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-016-0506-z