Abstract

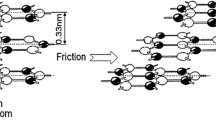

In this work, various concentrations of h-BN were added to the sintered porous (27.8 %) bearings and tested with three different mineral oil lubricants (hydrocarbon and refined) of varying viscosities. Tests were carried out to a working temperature of 150 °C and the tribological properties of the sintered bearings were investigated. It was found that the optimum concentration (5 wt% h-BN) greatly improved these properties. These properties and their parameters such as hardness, wear resistance, friction coefficient, lubricant viscosity, friction forces, and temperature are discussed in depth.

Similar content being viewed by others

References

Rapoport L, Leshchinsky V, Lvovsky M, Lapsker I, Volovik Yu, Tenne R (2002) Load bearing capacity of bronze, iron and iron-nickel powder composites containing fullerene-like WS2 nanoparticles. Tribol Intern 35:47–53

Chen B, Bi Q, Yang J, Xi Y, Hao J (2008) Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composition. Tribol Intern 41:1145–1152

Pawlak Z, Kaldonski T, Pai R, Bayraktar E, Oloyede A (2009) A comparative study on the tribological behaviour of hexagonal boron nitride (h-BN) as lubricating micro- particles—an additive in porous sliding bearings for a car clutch. Wear 267:1198–1202

Pawlak Z, Kaldonski T, Urbaniak W (2010) A hexagonal boron nitride-based model of porous bearings with reduced friction and increased load. Proc Inst Mech Eng Part J J Eng Tribol 224:1247–1253

Pawlak Z, Urbaniak W, Kałdonski T, Oloyede A (2013) Importance of bearing porosity in engineering and natural lubrication. In: Davim JP (ed) Biomaterials and medical tribology: research and development in Woodhead Publishing reviews: mechanical engineering series, chapt 7. pp 311–353. https://www.researchgate.net/publication/257304446_Importance_of_bearing_porosity_in_engineering_and_natural_lubrication

Kałdoński T (2013) Tribologiczne zastosowania azotku boru (tribological aplications of boron nitride), 2nd edn. MUT, Warsaw (in Polish)

Kałdoński T, Król A, Giemza B, Gocman K, Kałdoński TJ (2012) Development, testing and preparation for implementation of porous plain bearings of new generation with increased load capacity and durability, impregnated with eco-friendly lubricants containing selected surfactants, including ionic liquids, in the military technology. Final report about realization of development and research project no. PBR/15-249/2007/WAT/-OR00002904, MUT, (in Polish)

Kałdoński TJ, Kałdoński T (2006) Physicochemical self-lubricating mechanism of porous sliding bearings. Solid State Phenom 13:405–410

Kałdoński T, Krzemiński K, Kulczycki A, Szczawnicka E, Włodarczyk E (1997) Olej smarowy zawierający azotek boru α-BN, zwłaszcza do nasycania porowatych łożysk ślizgowych (Lubrication oil containing boron nitride α-BN, especially for impregnation of porous sliding bearings) – Polish Patent-P321029

Kałdoński T, Krzemiński K, Kulszewicz I, Szczawnicka E (1999) Smar plastyczny, zwłaszcza do nasycania porowatych łożysk ślizgowych (Flexible lubricant especially for impregnation of porous slide bearings) – Polish Patent-P332485

Kałdoński T, Król A, Giemza B, Gocman K, Kałdoński TJ (2012) Porowate łożyska ślizgowe spiekane z proszku żelaza z dodatkiem heksagonalnego azotku boru h-BN (Porous slide bearings sintered from iron powder with addition of hexagonal boron nitride h-BN) – Polish Patent-P401050

Wierzcholski K (2010) Friction force and pressure calculations for time dependent impulsive intelligent lubrication of human hip joint. Acta Bioeng Biomech 12:95–101

Nikas GK, Sayles RS (2008) A study of lubrication mechanisms using two-phase fluids with porous bearing materials. Proc Inst Mech Eng Part J J Eng Tribol 222:771–783

Galda L, Dzierwa A, Pawlus P, Reizer R (2011) Improvement of tribological properties of co-acting elements by oil pockets creation on sliding surfaces. Meccanica 46:523–534

Walicki E, Walicka A, Makhaniok A (2001) Thrust bearing with one porous wall lubricated by a bingham fluid. Meccanica 36:709–716

Urbaniak W, Kałdoński T, Hagner-Derengowska M, Kałdoński TJ, Madhani JT, Kruszewski Pawlak Z (2015) Impregnated porous bearings textured with a pocket on sliding surfaces: comparison of h-BN with graphite and MoS2 up to 150 °C. Meccanica 50:1343–1349

Stachowiak GW, Batchelor AW (2005) Engineering Tribology, 3rd edn. Elsevier, Oxford

Pawlak Z (2003) Tribochemistry of Lubricating Oils. Elsevier, Amsterdam

Acknowledgments

The authors would like to thank the anonymous reviewers for their invaluable comments for improving the quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Urbaniak, W., Kaldonski, T., Kaldonski, T.J. et al. Hexagonal boron nitride as a component of the iron porous bearing: friction on the porous sinters up to 150 °C. Meccanica 51, 1157–1165 (2016). https://doi.org/10.1007/s11012-015-0277-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-015-0277-y