Abstract

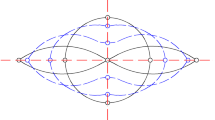

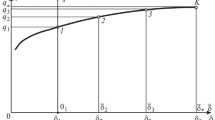

The main objective in this paper is to develop an analytical solution of burst pressure for pipe elbow containing the effect of yield to tensile strength (Y/T) ratio. By non-linear regression analysis, available experimental data between the strain hardening exponent and Y/T ratio were fitted to mathematical models with high values of correlation coefficients. Meanwhile, in order to reflect the effect of different yield criteria on the burst pressure, the unified yield criterion is used and an analytical solution of burst pressure expressed as a function of parameter b, Y/T ratio, curvature impact factor and the ratio of thickness to radius is ultimately derived. Comparison with traditional theoretical results and numerical results shows that the present Mises results considering the effect of Y/T ratio match the best with numerical results. Validation with experimental results is carried out and the present TSS criterion provides the best agreement with experimental ones. Moreover, the effects of parameter b, strain hardening exponent, Y/T ratio, curvature impact factor, as well as the ratio of thickness to radius on the burst pressure are also discussed systematically.

Similar content being viewed by others

References

Miller AG (1988) Review of limit loads of structures containing defects. Int J Pres Ves Pip 32:197–327

Griffiths JE (1979) The effect of cracks on the limit load of pipe bends under in-plane bending: experimental study. Int J Mech Sci 21:119–130

Hilsenkpf P, Boneh B, Sollogoub P (1988) Experimental study of behavior and functional capability of ferritic steel elbows and unstenitic stainless steel thin-walled elbows. Int J Pres Vessel Pip 33:111–128

Kim YJ, Oh CS (2006) Closed-form plastic collapse loads of pipe bends under combined pressure and in-plane bending. Eng Fract Mech 73:1437–1454

Kim YJ, Kim YI, Song TK (2007) Finite element plastic loads for circumferential cracked pipe bends under in-plane bending. Eng Fract Mech 74(5):643–668

Kim JH, Hong SP, Kim YJ (2009) Limit pressures of 90° elbows with circumferential cracked part-through surface cracks. Eng Fract Mech 76(14):2202–2216

Shalaby MA, Younan MYA (1998) Limit loads for pipe elbows under in plane closing bending moment. ASME J Press Vessel Technol 120:35–42

Chattopadhyay J, Nathani DK, Kushwaha HS (2000) Closed-form collapse moment equations of elbows under combined internal pressure and in-plane bending moment. ASME J Press Vessel Technol 122:431–436

NISA (1997) A general purpose finite element program, Windows NT/95 Production Version. ML: Engineering Mechanics Research Center

Zhu X, Leis BN (2007) Theoretical and numerical predictions of burst pressure of pipelines. Trans ASME 129:644–652

Ma B, Shuai J, Liu D, Xu K (2013) Assessment on failure pressure of high strength pipeline with corrosion defects. Eng Fail Anal 32:209–219

Zhu X, Leis BN (2005) Influence of yield-to-tensile strength ratio on failure assessment of corroded pipelines. Trans ASME 127:436–442

Milner JL, Bunget C, Abu-Farha F, Kurfess T, Hammond VH (2013) Modeling tensile strength of materials processed by accumulative roll bonding. J Manuf Process 15:219–226

Sloterdijk W (1995) The influence of the yield-to-tensile ratio on deformation controlled pipeline behaviour. In: Proceedings of the 10th biennial joint technical meeting on line pipe research, Cambridge, UK: British Steel, 18–21

Yu MH, He LN (1991) A new model and theory on yield and failure of materials under complex stress state. Pergamon Press, Oxford

Yu MH (1992) A new system of strength theory. X’ian Jiaotong University Print, X’ian (in Chinese)

Lode W (1926) Versuche über den Einfluß der mittleren Hauptspannung auf das Fließen der Metalle Eisen. Kupfer und Nickel. Zeitschrift für Physik 36(11–12):913–939

Taylor GI, Quinney H (1931) The plastic distortion of metals. Philos Trans R Soc Lond Ser A Contain Pap Math Phys Character 230:323–362

Ivey HJ (1961) Plastic stress–strain relations and yield surfaces for aluminium alloys. J Mech Eng Sci 3(1):15–31

Mair WM, Pugh HLD (1964) Effect of pre-strain on yield surfaces in copper. J Mech Eng Sci 6(2):150–163

Yu MH (2004) Unified strength theory and its applications. Springer, Berlin

Ma GW, Iwasaki S, Miyamoto Y, Deto H (1999) Dynamic plastic behavior of circular plate using unified yield criterion. Int J Solids Struct 36:3257–3275

Zhang Y, Qiang HF, Yang YC (2007) Unified solutions to mixed mode crack tip under small scale yielding. Chin J Mech Eng 43(2):50–54 (in Chinese)

Wang LZ, Zhang YQ (2011) Plastic collapse analysis of thin-walled pipes based on unified yield criterion. Int J Mech Sci 53(5):348–354

Zhao DW, Jing L, Liu XH et al (2009) Deduction of plastic work rate per unit volume for unified yield criterion and its application. Trans Nonferrous Met Soc China 19(3):657–660

Zhang SH, Gao CR, Zhao DW et al (2013) Limit analysis of defect-free pipe elbow under internal pressure with mean yield criterion. J Iron Steel Res Int 20(4):11–15

Klever FJ (1992) Burst pressure of corroded pipe: flow stress revisited. In: Offshore technology conference (OTC), Houston

Stewart G, Klever FJ, Ritchie D (1994) An analytical model to predict the burst capacity of pipelines. In: Proceedings of the offshore mechanics and arctic engineering (OMAE1994), vol V, Houston, p 177–187

Maes MA, Salama MM, Dann M (2006) Reliability of burst limit states for damaged and corroded high strength pipelines. In: Proceeding of the offshore mechanics and arctic engineering (OMAE2006), Hamburg

Maes MA, Dann M, Salama MM (2008) Influence of grade on the reliability of corroding pipelines. Reliab Eng Syst Saf 93:447–455

Leis BN, Kilinski TJ (2000) Mechanical and fracture properties essential in integrity management of steel transition pipelines. Final Report PR-3-9737, PRCI Catalog No. L51845, December, 2000

American Petroleum Institute (2007) Fitness-for-service, API RP-579-1/ASME FFS-1

Hill R (1998) The mathematical theory of plasticity. Oxford University Press, Oxford

Li CM, Zhao DW, Zhang SH et al (2011) Analysis of burst pressure for X80 steel pipeline with MY criterion. J Northeast Univ 32(7):964–969 (in Chinese)

Zhu XK, Leis BN (2005) Influence of yield-to-tensile strength ratio on failure assessment of corroded pipelines. J Press Vessel Technol 127(4):435–442

Guo CX, Dong QW, Wu XZ et al (2001) Plastic collapse load analysis of the pipe elbows. Petro-chem Equip 30(6):8–10 (in Chinese)

Kim YJ, Lee KH, Oh CS et al (2007) Effect of bend angle on plastic loads of pipe bends under internal pressure and in-plane bending. Int J Mech Sci 49:1413–1424

Guo CX (1999) Plastic limit loads for surface defect pipes and bends under combined loads of tension, bending, torsion and internal pressure. East Chian University of Science and Technology, Shanghai

Duan ZX, Shen SM (2004) Analysis and experiments on the plastic limit load of elbows. Press Vessel Technol 21(8):1–4 (in Chinese)

Guo CX, Wang XS, Wang DB (2001) Plastic collapse load analysis of undefected pipe elbows under the complex loads. Press Vessel Technol 18(4):8–11 (in Chinese)

Ma JH, Zhu FX (2013) Analyzing plastic limit load of elbow pipe under internal pressure with Triple-shear Unified Yield Criterion. Mech Sci Technol Aerosp Eng 32(012):1841–1845 (in Chinese)

Choi JB, Goo BK, Kim JC et al (2003) Development of limit load solutions for corroded gas pipelines. Int J Press Vessels Pip 80(2):121–128

Chiodo MSG, Ruggieri C (2009) Failure assessments of corroded pipelines with axial defects using stress-based criteria: numerical studies and verification analyses. Int J Press Vessels Pip 86(2):164–176

Acknowledgments

The authors wish to acknowledge the Natural Science Foundation for the Youth (Grant No. 51305285), the Basic Research Program of Jiangsu Province (Grant No. BK20140334, 20130304), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 14KJB460024) and the Project Funded by China Postdoctoral Science Foundation (Grant No. 2014M561707). The authors also wish to acknowledge valuable suggestions from reviewers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, S.H., Chen, X.D., Wang, X.N. et al. Modeling of burst pressure for internal pressurized pipe elbow considering the effect of yield to tensile strength ratio. Meccanica 50, 2123–2133 (2015). https://doi.org/10.1007/s11012-015-0148-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-015-0148-6