Abstract

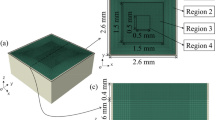

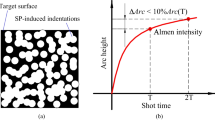

In this paper, we investigate the effect of the initial surface finish of the target on shot peening effectiveness using realistic 3D finite element simulations. Specifically, a large number of random shot impingements were simulated using an enhanced periodic cell model. The target material which is made from TI-6Al-4V is assumed to be strain-rate sensitive and follows the kinematic hardening law. ABAQUS/PYTHON scripts were developed to average the peening residual stresses at each depth of the target, and to calculate the corresponding surface roughness. The simulation was validated by comparing the results with the published work in literature. The periodicity of the model was also examined and verified. The model is further used to investigate the effect of the initial surface roughness on the effectiveness of the shot-peening treatment. The evolutions of the residual stress, plastic strain and the surface morphology during the peening process have all been investigated and the results discussed. The work reveals that a rough surface finish can lead to major reduction in the effectiveness of the shot peening treatment in terms of the generation of the highly beneficial compressive residual stresses.

Similar content being viewed by others

References

Abaqus Analysis User’s Manual, version 6.11. Dassault Systèmes Simulia Corp., Providence, RI (2011)

Ahmad, A., Crouch, E.D.: Dual shot peening to maximize beneficial residual stresses in carburized steels. In: Krauss, G. (ed.) Carburizing: Processing and Performance: Proceedings of an International Conference, pp. 277–281. ASM international, Materials Park (1989)

Al-Hassani, S.T.S.: Mechanical aspects of residual stress development in shot peening. In: Proceedings of ICSP-1, Paris, p. 583–602 (1981)

Bhuvaraghan, B., Srinivasan, S.M., Maffeo, B., Prakash, O.: Analytical solution for single and multiple impacts with strain-rate effects for shot peening. Comput. Model. Eng. Sci. 57, 137–158 (2010)

Chaudhuri, J., Donley, B.S., Gondhalekar, V., Patni, K.M.: The effect of hole drilling on fatigue and residual stress properties of shot-peened aluminum panels. J. Mater. Eng. Perform. 3, 726–733 (1994)

Davim, J.P.: Surface Integrity in Machining. Springer, Berlin (2010)

Edberg, J., Lindgren, L., Ken-Ichiro, M.: Shot peening simulated by two different finite element formulations. In: Shen, S.F., Dawson, P. (eds.) Simulation of Materials Processing: Theory, Methods and Applications, pp. 425–430. Balkema Publishers, Rotterdam (1995)

Frija, M., Hassine, T., Fathallah, R., Bouraoui, C., Dogui, A.: Finite element modelling of shot peening process: prediction of the compressive residual stresses, the plastic deformations and the surface integrity. Mat. Sci. Eng. A 426, 173–180 (2006)

Foss, B.J., Gray, S., Hardy, M.C., Stekovic, S., McPhail, D.S., Shollock, B.A.: Analysis of shot-peening and residual stress relaxation in the nickel-based superalloy RR1000. Acta Mater. 61, 2548–2559 (2013)

Hammond, D.W., Meguid, S.A.: Crack propagation in the presence of shot peening residual stresses. Eng. Fract. Mech. 37, 373–387 (1990)

Hong, T., Ooi, J.Y., Shaw, B.A.: A numerical study of the residual stress pattern from single shot impacting on a metallic component. Adv. Eng. Softw. 39, 743–756 (2008a)

Hong, T., Ooi, J.Y., Shaw, B.: A numerical simulation to relate the shot peening parameters to the induced residual stresses. Eng. Fail. Anal. 15, 1097–1110 (2008b)

Jiang, X.P., Man, C.S., Shepard, M.J., Zhai, T.: Effects of shot-peening and re-shot-peening on four-point bend fatigue behavior of Ti–6Al–4V. Mater. Sci. Eng. A 468, 137–143 (2007)

Kim, T., Lee, H., Hyun, H., Jung, S.: Effects of Rayleigh damping, friction and rate-dependency on 3D residual stress simulation of angled shot peening. Mater. Design 46, 26–37 (2013)

Klemenz, M., Schulze, V., Rohr, I., Lohe, D.: Application of the FEM for the prediction of the surface layer characteristics after shot peening. J. Mater. Process. Tech. 209, 4093–4102 (2009)

Kobayashi, M., Matsui, T., Murakami, Y.: Mechanism of creation of compressive residual stress by shot peening. Int. J. Fatigue 20, 351–357 (1998)

Li, A.K., Yao, M., Wang, D., Wang, R.: Mechanical approach to the residual stress field induced by shot-peening. Mater. Sci. Eng. A 147, 167–173 (1991)

Majzoobi, G.H., Azizi, R., Alavi Nia, A.: A three-dimensional simulation of shot peening process using multiple shot impacts. J. Mater. Process. Technol. 164, 1226–1234 (2005)

Meguid, S.A.: Impact Surface Treatment. Elsevier Applied Science, Amsterdam (1986)

Meguid, S.A., Shagal, G., Stranart, J.C.: 3D FE analysis of peening of strain-rate sensitive materials using multiple impingement model. Int. J. Impact Eng 27, 119–134 (2002)

Meguid, S.A., Shagal, G., Stranart, J.C., Daly, J.: Three-dimensional dynamic finite element analysis of shot-peening induced residual stresses. Finite Elements Anal. Des. 31, 179–191 (1999a)

Meguid, S.A., Shagal, G., Stranart, J.C.: Finite element modelling of shot-peening residual stresses. J. Mater. Proces. Tech. 92, 401–404 (1999b)

Meguid, S.A., Shagal, G., Stranart, J.C.: Development and validation of novel FE models for 3D analysis of peening of strain-rate sensitive materials. J. Eng. Mater. Tech. 129, 271–283 (2007)

Mylonas, G.I., Labeas, G.: Numerical modelling of shot peening process and corresponding products: residual stress, surface roughness and cold work prediction. Surf. Coat. Tech. 205, 4480–4494 (2011)

Noyan, I.C., Cohen, J.B.: An X-ray diffraction study of the residual stress-strain distributions in shot-peened two-phase brass. Mater. Sci. Eng. 75, 179–193 (1985)

Nobre, J.P., Kornmeier, M., Dias, A.M., Scholtes, B.: Use of the hole-drilling method for measuring residual stresses in highly stressed shot-peened surfaces. Exp. Mech. 40, 289–297 (2000)

Park, K.D., Jung, C.G.: The effect of compressive residual stresses of two-stage shot peening for fatigue strength of spring steel. In: Proceedings of the 12th International Offshore and Polar Engineering Conference Kitakyushu, Japan, May 26–31, pp. 220–223 (2002)

Peirs, J., Verleysen, P., Degrieck, J.: Study of the dynamic Bauschinger effect in Ti–6Al4V by torsion experiments. EPJ Web of Conferences 26, 01023 (2012). doi:10.1051/epjconf/20122601023

Premack, T., Douglas, A.S.: Three-dimensional analysis of the impact fracture of 4340 steel. Int. J. Solids Struct. 32, 2793–2812 (1995)

Prevey, P.S.: X-ray diffraction characterization of residual stresses produced by shot peening. In: Eckersley, J.S., Champaigne, J. (eds.) Shot Peening—Theory and Applications, pp. 81–93. IITT-International, Gournay-sur-Marne (1991)

Schiffner, K., Droste gen. Helling, C.: Simulation of residual stresses by shot peening. Comput. Struct. 72, 329–340 (1999)

Schulze, V.: Modern Mechanical Surface Treatment. Wiley-VCH, Weinheim (2006)

Sheng, X.F., Xia, Q.X., Cheng, X.Q., Lin, L.S.: Residual stress field induced by shot peening based on random-shots for 7075 aluminum alloy. Trans. Nonferrous Met. Soc. China 22, s261–s267 (2012)

Torres, M.A.S., Voorwald, H.J.C.: An evaluation of shot peening, residual stress and stress relaxation on the fatigue life of AISI 4340 steel. Int. J. Fatigue 24, 877–886 (2002)

Yang, F., Chen, Z., Meguid, S.A.: 3D FE modeling of oblique shot peening using a new periodic cell. Int. J. Mech. Mater. Des. 10, 133–144 (2013)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, F., Chen, Z. & Meguid, S.A. Effect of initial surface finish on effectiveness of shot peening treatment using enhanced periodic cell model. Int J Mech Mater Des 11, 463–478 (2015). https://doi.org/10.1007/s10999-014-9273-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-014-9273-y