Abstract

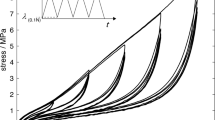

In this work, a new visco-hyperelastic constitutive model is proposed to describe the rate-dependent large deformation behaviour of an acrylic elastomer. The proposed model is based on the Zener model, which consists of a hyperelastic equilibrium spring and a Maxwell element to capture rate-dependent material response. The constitutive equation is based on the history integral of Gent strain energy function. The material constants of the developed model are determined with the aid of available different rate-dependent uniaxial tensile experimental results. The proposed model is validated with the earlier published experimental results of VHB 4910 acrylic elastomer which is considered now as one of the promising actuator materials. Fittings of the proposed model with the earlier published experimental results and present experimental stress-stretch results in different strain rates are found to be in good agreement.

Similar content being viewed by others

References

Arruda, E.M., Boyce, M.C.: A three-dimensional constitutive model for large stretch behaviour of rubber elastic materials. J. Mech. Phys. Solids 41, 389–412 (1993)

Anani, Y., Alizadeh, Y.: Visco-hyperelastic constitutive law for modeling of foam’s behavior. Mater. Des. 32, 2940–2948 (2011)

Beatty, M.F., Krishnaswamy, S.: A theory of stress-softening in incompressible isotropic materials. J. Mech. Phys. Solids 48, 1931–1965 (2000)

Bergstrom, J.S., Boyce, M.C.: Constitutive modeling of the large strain time-dependent behavior of elastomers. J. Mech. Phys. Solids 46(5), 931–954 (1998)

Biddiss, E., Chau, T.: Dielectric elastomers as actuators for upper limb prosthetics: challenges and opportunities. Med. Eng. Phys. 30, 403–418 (2008)

Carpi, F., Rossi, D.D., Kornbluh, R., Pelrine, R., Sommer-Larsen, P.: Dielectric Elastomers as Electromechanical Transducers: Fundamentals, Materials, Devices, Models and Applications of an Emerging Electroactive Polymer Technology. Elsevier science, Oxford (2008)

Chakraborti, P., Toprakci, H.A.K., Yang, P., Spigna, N.D., Franzon, P., Ghosh, T.: A compact dielectric elastomer tubular actuator for refreshable Braille displays. Sens. Actuators A 179, 151–157 (2012)

Chiba, S., Waki, M.: Extending applications of dielectric elastomer artificial muscles to wireless communication systems. InTech, Rijeka, Croatia 20 (2011)

Chiba, S., Waki, M., Wada, T., Hirakawa, Y., Masuda, K., Ikoma, T.: Consistent ocean wave energy harvesting using electroactive polymer (dielectric elastomer) artificial muscle generators. Appl. Energy 104, 497–502 (2013)

Choi, H.R., Ryew, S.M., Jung, K.M., Kim, H.M., Jeon, J.W., Nam, J.D.: Soft actuator for robotic applications based on dielectric elastomer: quasi-static analysis. IEEE Int. Conf. Robot. Autom. 3, 3212–3217 (2002)

Foo, C.C., Cai, S., Koh, S.J.A., Bauer, S., Suo, Z.: Model of dissipative dielectric elastomers. J. Appl. Phys. 111, 034102 (2012)

Gent, A.N.: A new constitutive relation for rubber. Rubber Chem. Technol. 69, 59–61 (1996)

Goulbourne, N.C.: A constitutive model of polyacrylate interpenetrating polymer networks for dielectric elastomers. Int. J. Solids Struct. 48, 1085–1091 (2011)

Hong, W.: Modeling viscoelastic dielectrics. J. Mech. Phys. Solids. 59, 637–650 (2011)

Horgan, C.O., Saccomandi, G.: A molecular-statistical basis for the gent constitutive model of rubber elasticity. J. Elast. 68, 167–176 (2002)

Hossain, M., Khoi, VuD, Steinmann, P.: Experimental study and numerical modelling of VHB 4910 polymer. Comput. Mat. Sci. 59, 65–74 (2012)

Kofod, G.: Dielectric Elastomer Actuator, PhD thesis Technical University of Denmark (2001)

Koh, S.J.A., Keplinger, C., Li, T., Bauer, S., Suo, Z.: Dielectric elastomer generators: how much energy can be converted? IEEE/ASME Trans. Mechatron. 16(1), 33–41 (2011)

Leng, J., Liu, L., Liu, Y., Yu, K., Sun, S.: Electromechanical stability of dielectric elastomers. Appl. Phys. Lett. 94, 211901 (2009)

Li, T., Keplinger, C., Baumgartner, R., Bauer, S., Yang, W., Suo, Z.: Giant voltage-induced deformation in dielectric elastomers near the verge of snap-through instability. J. Mech. Phys. Solids 61, 611–628 (2013a)

Li, T., Keplinger, C., Baumgartner, R., Bauer, S., Yang, W., Suo, Z.: Giant voltage induced deformation in dielectric elastomers near the verge of snap-through instability. J. Mech. Phys. Solids 61, 611–628 (2013b)

Linder, C., Tkachuk, M., Miehe, C.: A micromechanically motivated diffusion-based transient network model and its incorporation into finite rubber viscoelasticity. J. Mech. Phys. Solids 59, 2134–2156 (2011)

Liu, Y., Liu, L., Zhang, Z., Shi, L., Leng, J.: Comment on “Method to analyze electromechanical stability of dielectric elastomers”. Appl. Phys. Lett. 93, 106101 (2008)

Liu, Y., Liu, L., Zhang, Z., Leng, J.: Dielectric elastomer film actuators: characterization, experiment and analysis. Smart Mater. Struct. 18, 095024 (2009a)

Liu, Y., Liu, L., Yu, K., Sun, S., Leng, J.: An investigation on electromechanical stability of dielectric elastomers undergoing large deformation. Smart Mater. Struct. 18, 095024 (2009b)

Liu, Y., Liu, L., Zhang, Z., Jiao, Y., Sun, S., Leng, J.: Analysis and manufacture of an energy harvester based on a Mooney-Rivlin-type dielectric elastomer. EPL 90(3), 36004 (2010)

Liu, Y., Liu, L., Luo, X., Li, B., Leng, J.: Electromechanical stability and snap-through stability of dielectric elastomers undergoing polarization saturation. Mech. Mater. 55, 60–72 (2012)

Liu, Y., Liu, L., Yu, K., Leng, J.: Thermoelectromechanical stability of dielectric elastomer undergoing temperature variation. Mech. Mater. 72, 33–45 (2014)

Lockett, F.J.: Non-linear Viscoelastic Solids. Academic Press, New York (1972)

Lochmatter, P., Kovacs, G., Micheal, S.: Characterization of dielectric elastomer actuators based on a hyperelastic film model. Sens. Actuators A 135, 748–757 (2007)

Ogden, R.W.: Large deformation isotropic elasticity-on the correlation of theory and experiment for incompressible rubberlike solids. Proc. Royal Soc. Lond. A 326, 565–584 (1972)

Pang X., Li B., Xia D., Jing S.: Application of dielectric elastomer planar actuators in a micropump chip, ICIEA 2009, 978-1-4244-2800-7/09, 1199–1202 (2009)

Pelrine, R., Kornbluh, R., Eckerle, J., Jeuck, P., Oh, S., Pei, Q., Stanford, S.: Dielectric elastomers: generator mode fundamentals and applications. Proc. SPIE. 4329, 148–156 (2001)

Plante, J.S., Dubowsky, S.: Large-scale failure modes of dielectric elastomer actuators. Int. J. Solids Struct. 43, 7727–7751 (2006)

Rivlin, R.S.: Large elastic deformations of isotropic materials. IV. Further developments of the general theory. Philos. Trans. Royal Soc. A 241, 379–397 (1948)

Shankar, R., Ghosh, T.K., Spontak, R.J.: Dielectric elastomers as next-generation polymeric actuators. Soft Matter 3, 1116–1129 (2007)

Shim, V.P.W., Yang, L.M., Lim, C.T., Law, P.H.: A visco-hyperelastic constitutive model to characterize both tensile and compressive behavior of rubber. J. Appl. Polym. Sci. 92, 523–531 (2004)

Wang, Y., Xue, H., Chen, H., Qiang, J.: A dynamic visco-hyperelastic model of dielectric elastomers and their energy dissipation characteristics. Appl. Phys. A 112(2), 339–347 (2013)

Wissler, M., Mazza, E.: Mechanical behavior of an acrylic elastomers used in dielectric elastomers actuators. Sens. Actuators A 134, 494–504 (2007)

Yang, L.M., Shim, V.P.W.: A visco-hyperelastic constitutive description of elastomeric foam. Int. J. Impact Eng. 30, 1099–1110 (2004)

Yeoh, O.H.: Some forms of the strain energy function for rubber. Rubber Chem. Tech. 66, 754–771 (1993)

Zhang, J., Chen, H., Sheng, J., Liu, L., Wang, Y., Jia, S.: Constitutive relation of viscoelastic dielectric elastomers. Theor. Appl. Mech. Lett. 3, 054011 (2013)

Zhao, X., Suo, Z.: Method to analyze programmable deformation of dielectric elastomer layers. Appl. Phys. Lett. 93, 251902 (2008a)

Zhao, X., Suo, Z.: Electrostriction in elastic dielectrics undergoing large deformation. J. Appl. Phys. 104, 123530 (2008b)

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

1.1 A.1 Fundamentals of hyperelasticity of elastomer

Study of highly nonlinear elastic materials undergoing large deformation is called as hyperelasticity and the material is special case of Cauchy elastic material (Beatty and Krishnaswamy 2000). However for large deformations, stresses are derived from the strain energy potential function \( W \) which is usually expressed in the form of deformation gradient tensor \( \varvec{F} \) and the principal invariants. \( \varvec{F} \) relates physical quantities from their initial and deformed state. Consider a point initially located at some position X in a material. Displacement of a new position x after deformation gradient \( \varvec{F} \) is defined as \( \varvec{F} = {{\partial x} \mathord{\left/ {\vphantom {{\partial x} {\partial X}}} \right. \kern-0pt} {\partial X}} \).

Generally deformation of the elastomeric material will be expressed in terms of the left Cauchy-Green deformation tensor \( \varvec{B} = \varvec{F} \cdot \varvec{F}^{T} \), or by the right Cauchy-Green deformation tensor \( \varvec{C} = \varvec{F}^{T} \cdot \varvec{F} \) which is related to Langrangian strain tensor denoted by \( \varvec{E} = {{\left( {\varvec{C} - \varvec{I}} \right)} \mathord{\left/ {\vphantom {{\left( {\varvec{C} - \varvec{I}} \right)} 2}} \right. \kern-0pt} 2} \) where \( \varvec{I} \) is the identity tensor.

Simply, we can write \( \frac{{\partial \varvec{E}}}{{\partial \varvec{C}}} = \frac{1}{2} \) (A.1)

If a material is said to be path-independent or hyperelastic then the work done by the stresses during deformation process depends only on its initial and final configurations at time 0 and t respectively.

Therefore path-independent strain energy function

where \( \varvec{S} \) is second Piola-Kirchoff stress tensor and \( \dot{\varvec{E}} \) = time rate of change of Lagrangian strain tensor

Assuming W = W( E ( \( {\mathbf{X}} \) ), \( {\mathbf{X}} \) ) then \( \dot{W} = \sum\limits_{i,j = 1}^{3} {\frac{\partial W}{{\partial \varvec{E}_{ij} }}} \dot{\varvec{E}}_{ij} \) (A.3)

On comparing Eq. (A.2) and Eq. (A.3), one gets

Therefore by using Eqs. (A.1) and (A.4), one will get

Strain energy potential function,\( W = W\left( {I_{1} ,I_{2} ,I_{3} } \right) \), where \( I_{1},\,I_{2} \) and \( I_{3} \) are first, second and third invariants of the right Cauchy-Green deformation tensor C.

where, \( \lambda_{1} ,\lambda_{2} , \) and \( \lambda_{3} \) are principal stretches in three directions.

With the application of chain rule,

Since \( \frac{{\partial I_{1} }}{{\partial \varvec{C}}} = \varvec{I, }\,\frac{{\partial I_{2} }}{{\partial \varvec{C}}} = I_{1} \varvec{I} - \varvec{C}\,{\text{and}}\,\frac{{\partial I_{3} }}{{\partial \varvec{C}}} = I_{3} \varvec{C}^{ - 1} \) (A.10)

Equation (A.9) can be written as

Transformation of the second Piola-Kirchoff stress to Cauchy stress tensor \( \varvec{\sigma} \) results

where, \( J = det\varvec{F} \), where \( \varvec{F} = \left[ {\begin{array}{*{20}c} {\lambda_{1} } & 0 & 0 \\ 0 & {\lambda_{2} } & 0 \\ 0 & 0 & {\lambda_{3} } \\ \end{array} } \right] \)

Using Eqs. (A.11) and (A.12), \( \varvec{\sigma} \) can be written as

Since, \( \varvec{B} = \varvec{FF}^{T} ,\,\;\varvec{FF}^{ - 1} = \varvec{I}\;and\;\varvec{F}^{ - T} \varvec{F}^{T} = \varvec{I} \)

Therefore

Considering incompressibility of the material, \( I_{3} = 1\;\; \) and \( J = 1 \)

Cauchy stress at equilibrium condition can be written as

where, p is hydrostatic pressure and W is strain energy function in equilibrium state.

1.2 A.2 Gent Model

The strain energy density function for the Gent model (Gent, 1996) is

where \( \mu \) is the shear modulus, J m is the limiting value for \( \left( {I_{1} - 3} \right) \), reflecting limiting chain extensibility.

Since \( W = W\left( {I_{1} } \right) \), \( \frac{\partial W}{{\partial I_{2} }} = 0 \)

Cauchy stress tensor shown in Eq. (A.15) will become

Using Eq. (A.16) and (A.17) Cauchy stress for the Gent model is expressed as

For uniaxial tensile extension deformation gradient

Left Cauchy-Green deformation tensor can be written as

where elements of tensor B is as follows;

For the uniaxial case

From Eq. (A.18)

As \( (\sigma_{22} = 0) \)

Using the Eqs. (A.20) and (A.22)

Hence

Since, \( \sigma_{eng} = \frac{1}{\lambda }\sigma_{11} \), Eq. (A.24) can be written in terms of engineering stress as

Rights and permissions

About this article

Cite this article

Patra, K., Sahu, R.K. A visco-hyperelastic approach to modelling rate-dependent large deformation of a dielectric acrylic elastomer. Int J Mech Mater Des 11, 79–90 (2015). https://doi.org/10.1007/s10999-014-9270-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-014-9270-1