Abstract

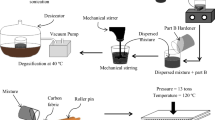

Composites based on an epoxy resin, diglycidyl ether of bisphenol A and SiO2 nanoparticles, unmodified and surface-modified with a coupling agent 3-glycidyloxypropyltrimethoxysilane, were prepared. Successful modification of the nanoparticles was confirmed by infrared spectroscopy and combined differential scanning calorimetry and thermogravimetric analysis (DSC–TG). Composite materials were prepared by adding 0.5–5 phr (parts per hundred parts of resin) of modified and unmodified nanoparticles into the epoxy resin which was then cured with a poly(oxypropylene) diamine. Curing was followed by DSC, and cured materials were characterised by tensile and hardness testing. Morphology of fractured surfaces after tensile testing was investigated by scanning electron microscopy (SEM). Thermal stability of cured materials was studied by TG and their glass transition temperature determined by DSC. The presence of the filler was found not to influence the curing mechanism of the epoxy resin nor the degradation mechanism of the crosslinked epoxy–amine matrix. Glass transition exhibits a small shift to higher temperatures in composites, which also exhibit increased char formation—at lower filler content for the composite with unmodified nanoparticles and at higher for the one with modified nanoparticles. All composites show improved mechanical properties in comparison with the neat epoxy. For the unmodified particles, strength and modulus are particularly improved at lower nanofiller content due to their better dispersion, as observed by SEM. The modified nanoparticles contributed to a significant increase in elongation at break, increasing the toughness of the cured resin while retaining its strength and without having an adverse influence on the modulus.

Similar content being viewed by others

References

Yee AF, Pearson RA. Toughening mechanisms in elastomer-modified epoxies—part 1 mechanical studies. J Mater Sci. 1986;21:2462–74.

Bucknall CB, Gilbert AH. Toughening tetrafunctional epoxy resins using polyetherimide. Polymer. 1989;30:213–7.

Gojny FH, Wichmann MHG, Köpke U, Fiedler B, Schulte K. Carbon nanotube-reinforced epoxy-composites: enhanced stiffness and fracture toughness at low nanotube content. Compos Sci Technol. 2004;64:2363–71.

Hodgkin JH, Simon GP, Varley RJ. Thermoplastic toughening of epoxy resins: a critical review. Polym Adv Technol. 1998;9:3–10.

Frigione ME, Mascia L, Acierno D. Oligomeric and polymeric modifiers for toughening of epoxy resins. Eur Polym J. 1995;31:1021–9.

Lebaron PC, Wang Z, Pinnavaia TJ. Polymer-layered silicate nanocomposites: an overview. Appl Clay Sci. 1999;15:11–29.

Tjong SC. Structural and mechanical properties of polymer nanocomposites. Mater Sci Eng R. 2006;53:73–197.

Battistella M, Cascione M, Fielder B, Wichmann MHG, Quaresimin M, Schulte K. Fracture behaviour of fumed silica/epoxy nanocomposites. Compos A. 2008;39:1851–8.

Baller J, Becker N, Ziehmer M, Thomassey M, Zielinski B, Müller U, Sanctuary R. Interactions between silica nanoparticles and an epoxy resin before and during network formation. Polymer. 2009;50:3211–9.

Vrsaljko D, Macut D, Kovačević V. Potential role of nanofillers as compatibilizers in immiscible PLA/LDPE blends. J Appl Polym Sci. 2015;132:41414.

Barabanova AI, Philippova OE, Askadskii AA, Khokhlov AR. Transparent epoxy/silica nanocomposites with increased glass transition temperatures. Procedia Chem. 2012;4:352–9.

Blackman BRK, Kinloch AJ, Sohn Lee J, Taylor AC, Agarwal R, Schueneman G, Sprenger S. The fracture and fatigue behaviour of nano-modified epoxy polymers. J Mater Sci. 2007;42:7049–51.

Bondioli F, Cannillo V, Fabbri E, Messori M. Epoxy-silica nanocomposites: preparation, experimental characterization, and modeling. J Appl Polym Sci. 2005;97:2382–6.

Jumahat A, Soutis C, Jones FR, Hodzic A. Effect of silica nanoparticles on compressive properties of an epoxy polymer. J Mater Sci. 2010;45:5973–83.

Rosso P, Ye L, Friedrich K, Sprenger S. A toughened epoxy resin by silica nanoparticle reinforcement. J Appl Polym Sci. 2006;100:1849–55.

Wichmann MHG, Cascione M, Fiedler B, Quaresimin M, Schulte K. Influence of surface treatment on mechanical behaviour of fumed silica/epoxy resin nanocomposites. Compos Interfaces. 2006;13:699–715.

Zhuravlev LT. The surface chemistry of amorphous silica. Zhuravlev model. Colloids Surf A. 2000;173:1–38.

Domingo C, Loste E, Fraile J. Grafting of trialkoxysilane on the surface of nanoparticles by conventional wet alcoholic and supercritical carbon dioxide deposition methods. J Supercrit Fluids. 2006;37:72–86.

Li X, Cao Z, Zhang Z, Dang H. Surface-modification in situ of nano-SiO2 and its structure and tribological properties. Appl Surf Sci. 2006;252:7856–61.

Hoebbel D, Nacken M, Schmidt H. The effect of nanoscaled metal oxide sols on the structure and properties of glycidoxypropyltrimethoxysilane derived sols and gels. J Sol–Gel Sci Technol. 2000;19:305–9.

Underhill PR, Goring G, Duquesnay DL. A study of the deposition of 3-glycidoxypropyltrimethoxysilane on aluminum. Int J Adhes Adhes. 1998;18:307–11.

Daniels MW, Francis LF. Silane adsorption behavior, microstructure, and properties of glycidoxypropyltrimethoxysilane-modified colloidal silica coatings. J Colloid Interface Sci. 1998;205:191–200.

Chu L, Daniels MW, Francis LF. Use of (glycidoxypropyl)trimethoxysilane as a binder in colloidal silica coatings. Chem Mater. 1997;9:2577–82.

Antonelli C, Serrano B, Baselga J, Ozisik R, Cabanelas JC. Interfacial characterization of epoxy/silica nanocomposites measured by fluorescence. Eur Polym J. 2015;62:31–42.

Fadeev AY, McCarthy TJ. Self-assembly is not the only reaction possible between alkyltrichlorosilanes and surfaces: monomolecular and oligomeric covalently attached layers of dichloro- and trichloroalkylsilanes on silicon. Langmuir. 2000;16:7268–74.

Dugas V, Chevalier Y. Surface hydroxylation and silane grafting on fumed and thermal silica. J Colloid Interface Sci. 2003;264:354–61.

van der Voort P, Vansant EF. Silylation of the silica surface: a review. J Liq Chromatogr Relat Technol. 1996;19:2723–31.

Sangermano M, Malucelli G, Amerio E, Priola A, Billi E, Rizza G. Photopolymerization of epoxy coatings containing silica nanoparticles. Prog Organ Coat. 2005;54:134–8.

Ragosta G, Abbate M, Musto P, Scarinzi G, Mascia L. Epoxy-silica particulate nanocomposites: chemical interactions, reinforcement and fracture toughness. Polymer. 2005;46:10506–16.

Gholamian F, Ghariban-Lavasani S, Garshasbi MM, Ansari M, Bataghv F, Moraveji A, Ranjbar Z. The effects of water absorption and surface treatment on mechanical properties of epoxy nanocomposite using response surface methodology. Polym Bull. 2013;70:1677–95.

Liu G, Zhang H, Zhang D, Zhang H, Zhang Z, An X, Yi X. On depression of glass transition temperature of epoxy nanocomposites. J Mater Sci. 2012;47:6891–5.

Zappalorto M, Pontefisso A, Fabrizi A, Quaresimin M. Mechanical behaviour of epoxy/silica nanocomposites: experiments and modelling. Compos A. 2015;72:58–64.

Liu YL, Hsu CY, Wei WL, Jeng RJ. Preparation and thermal properties of epoxy-silica nanocomposites from nanoscale colloidal silica. Polymer. 2003;44:5159–67.

Johnsen BB, Kinloch AJ, Mohammed RD, Taylor AC, Sprenger S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer. 2007;48:530–41.

Rosso P, Ye L. Epoxy/silica nanocomposites: nanoparticle-induced cure kinetics and microstructure. Macromol Rapid Commun. 2007;28:121–6.

Rivers G, Rogalsky A, Lee-Sullivan P, Zhao B. Thermal analysis of epoxy-based nanocomposites: Have solvent effects been overlooked? J Therm Anal Calorim. 2015;119:797–805.

Hsieh TH, Kinloch AJ, Masania K, Taylor AC, Sprenger S. The mechanisms and mechanics of the toughening of epoxy polymers modified with silica nanoparticles. Polymer. 2010;51:6284–94.

Bray DJ, Dittanet P, Guild FJ, Kinloch AJ, Masania K, Pearson RA, Taylor AC. The modelling of the toughening of epoxy polymers via silica nanoparticles: the effects of volume fraction and particle size. Polymer. 2013;54:7022–32.

Prolongo MG, Salom C, Arribas C, Sánchez-Cabezudo M, Masegosa RM, Prolongo SG. Influence of graphene nanoplatelets on curing and mechanical properties of graphene/epoxy nanocomposites. J Therm Anal Calorim. 2016;125:629–36.

Marouf BT, Mai Y-W, Bagheri R, Pearson RA. Toughening of epoxy nanocomposites: nano and hybrid effects. Polym Rev. 2016;56:70–112.

Liang YL, Pearson RA. Toughening mechanisms in epoxy–silica nanocomposites (ESNs). Polymer. 2009;50:4895–905.

Bittmann B, Haupert F, Schlarb AK. Ultrasonic dispersion of inorganic nanoparticles in epoxy resin. Ultrason Sonochem. 2009;16:622–8.

Zhang H, Tang LC, Zhang Z, Friedrich K, Sprenger S. Fracture behaviours of in situ silica nanoparticle-filled epoxy at different temperatures. Polymer. 2008;49:3816–25.

Acknowledgements

This study is a part of the research project “Bioceramic, Polymer and Composite Nanostructured Materials”, 125-1252970-3005, supported by the Ministry of Science, Education and Sports of the Republic of Croatia. The authors are grateful to Prof. Đ. Španiček and Mr. B. Bušetinčan from Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, for the ball indentation measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Macan, J., Paljar, K., Burmas, B. et al. Epoxy-matrix composites filled with surface-modified SiO2 nanoparticles. J Therm Anal Calorim 127, 399–408 (2017). https://doi.org/10.1007/s10973-016-5976-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5976-7