Abstract

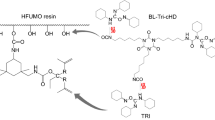

In order to study the curing reactions of hydroxyl-terminated polyether (HTPE) with a curing agent hexamethylene diisocyanate biuret (HDIB), the rheology and chemical processes of the curing reactions have been studied by simultaneous rheometry and FTIR spectroscopy. It was shown that the gel point was a key parameter in the curing reaction of HTPE with HDIB. The gel point was at the intersection of G′ and G″ curves. The gel point was when gelation occurred. After gelation, the polymer could not flow and the viscosity and real modulus increased rapidly. The curing reaction of the HTPE/HDIB kinetics system, monitored by an FTIR technique, showed a characteristic intensity peak at 2270 cm−1, corresponding to the –N=C=O stretching vibration which decreased as a function of time and the curing reaction of the HTPE/HDIB system and obeyed a three-dimensional (spherical symmetric) diffusion model.

Similar content being viewed by others

References

Kim KH, Kim CK, Yoo JC, et al. Test-based thermal decomposition simulation of AP/HTPB and AP/HTPE propellants. J Propuls Power. 2011;27:822–7.

Caro RI, Bellerby JM, Kronfli E. Synthesis and characterization of a hydroxy terminated polyether (HTPE) copolymer for use as a binder in composite rocket propellants. Int J Energ Mater Chem Propuls. 2007;6:289–306.

Huang ZP, Nie HY, Zhang YY, et al. Migration kinetics and mechanisms of plasticizers, stabilizers at interfaces of NEPE propellant/HTPB liner/EDPM insulation. J Hazard Mater. 2012;229:251–7.

Yan DQ, Xu DD, Shi JG. A review of solid propellant binder HTPE development and its molecular design philosophy. J Solid Rocket Technol. 2009;6:644–9.

Mao KZ, Xia M, Luo YJ, et al. Effect of curing agent types on properties of HTPE polyurethane elastomer films. Chin J Explos Propellants. 2012;1:55–8.

Zhang QF, Zhang JQ. Research and development of insensitive solid propellants. Energ Mater. 2004;6:371–5.

Hedman TD, Gross ML, Davis JJ, et al. Experimental investigation of the decomposition preceding cookoff in a composite propellant. J Propuls Power. 2014;30:1667–74.

Kim CK, Bae SB, Ahn JR, et al. Structure–property relationships of hydroxy-terminated polyether based polyurethane network. Polym Bull. 2008;61:225–33.

Hu J, Yuan P, Zeng K, et al. Study of the curing kinetics of a benzimidazole/phthalonitrile resin system. Thermochim Acta. 2014;590:30–9.

Naumann S, Speiser M, Schowner R, et al. Air stable and latent single-component curing of epoxy/anhydride resins catalyzed by thermally liberated N-heterocyclic carbenes. Macromolecules. 2014;47:4548–56.

Rusli A, Cook WD, Schiller TL. Blends of epoxy resins and polyphenylene oxide as processing aids and toughening agents 2: curing kinetics, rheology, structure and properties. Polym Int. 2014;63:1414–26.

Chen K, Tian C, Lu A, et al. Effect of SiO2 on rheology, morphology, thermal, and mechanical properties of high thermal stable epoxy foam. J Appl Polym Sci. 2014;131:2113–24.

Faria H, Pires F, Marques AT. Modeling the rheology of SR1500 and LY556 epoxies under manufacturer’s recommended cure cycles after viscosimetry and rheometry characterization. Polym Eng Sci. 2014;54:831–9.

Fukumoto T, Thomas PS, Šimon P, et al. Estimation of the curing rate of acrylamide used as a consolidant in heritage sandstone conservation. J Therm Anal Calorim. 2014;116:619–24.

Musto P, Larobina D, Cotugno S, et al. Confocal Raman imaging, FTIR spectroscopy and kinetic modelling of the zinc oxide/stearic acid reaction in a vulcanizing rubber. Polymer. 2013;54:685–93.

Omrani A, Simon L, Rostami A, et al. Cure kinetics FTIR study of epoxy/nickel–imidazole system. Int J Chem Kinet. 2008;40:663–9.

Sankar G, Nasar AS. Cure-reaction kinetics of amine-blocked polyisocyanates with alcohol using hot-stage Fourier transform infrared spectroscopy. J Appl Polym Sci. 2008;109:1168–76.

Shi Q, Huang W, Zhang Y, et al. Curing of polyester powder coating modified with rutile nano-sized titanium dioxide studied by DSC and real-time FT-IR. J Therm Anal Calorim. 2012;108:1243–9.

Arasa M, Ramis X, Salla JM, et al. Kinetic study by FTIR and DSC on the cationic curing of a DGEBA/γ-valerolactone mixture with ytterbium triflate as an initiator. Thermochim Acta. 2008;479:37–44.

Ramis X, Salla JM, Mas C, et al. Kinetic study by FTIR, TMA, and DSC of the curing of a mixture of DGEBA resin and γ-butyrolactone catalyzed by ytterbium triflate. J Appl Polym Sci. 2004;92:381–93.

He Y, Liao S, Chen Z, et al. Nonisothermal kinetics study with advanced isoconversional procedure and DAEM: LiNiPO4 synthesized from thermal decomposition of the precursor. J Therm Anal Calorim. 2014;115:1870–6.

Pourmortazavi SM, Farhadi K, Mirzajani V, et al. Study on the catalytic effect of diaminoglyoxime on thermal behaviors, non-isothermal reaction kinetics and burning rate of homogeneous double-base propellant. J Therm Anal Calorim. 2016; 1–8.

Halász L, Belina K. An investigation into the curing of epoxy powder coating systems. J Therm Anal Calorim. 2015;119:1–10.

Yi JH, Zhao FQ, Wang BZ, et al. BTATz–HNIW–CMDB propellants: decomposition reaction kinetics and thermal safety. J Therm Anal Calorim. 2014;115:1227–34.

Achilias DS. Investigation of the radical polymerization kinetics using DSC and mechanistic or isoconversional methods. J Therm Anal Calorim. 2014;116:1–8.

Zhang Y, Chen F, Liu W, et al. Rheological behavior of the epoxy/thermoplastic blends during the reaction induced phase separation. Polymer. 2014;55:4983–9.

Gu R, Mu B, Guo K. Rheological model of konjak powder-chitosan-polyvinyl alcohol blending adhesive. Trans Chin Soc Agric Eng. 2014;30:278–84.

Kalaee M, Mahdavi H, Famili MHN. Preparation of synthesized sulfide polymer through phase-transfer catalyzed polycondensation of ethylene dibromide and sodium tetrasulfide: characterization, thermal and rheological properties. J Sulfur Chem. 2014;35:1–9.

Zhang Q, Huang X, Wang X, et al. Rheological study of the gelation of cross-linking polyhedral oligomeric silsesquioxanes (POSS)/PU composites. Polymer. 2014;55:1282–91.

Li L, Miesch C, Sudeep P, et al. Kinetically trapped co-continuous polymer morphologies through intraphase gelation of nanoparticles. Nano Lett. 2011;11:1997–2003.

Kandpal S, Saxena A. Studies on the synthesis and reaction of silicone oxirane dendrimer and their thermal and rheological properties. Eur Polymer J. 2014;58:115–24.

Malkin AY, Arinstein A, Kulichikhin V. Polymer extension flows and instabilities. Prog Polym Sci. 2014;39:959–78.

Chang YH, Lin KF. Physisorption of ionic salts to carbon nanotubes for enhancing dispersion and thermomechanical properties of carbon nanotube-filled epoxy resins. Compos Sci Technol. 2014;90:174–9.

Xu J, Shi W, Pang W. Synthesis and shape memory effects of Si–O–Si cross-linked hybrid polyurethanes. Polymer. 2006;47:457–65.

Montembault A, Viton C, Domard A. Rheometric study of the gelation of chitosan in aqueous solution without cross-linking agent. Biomacromolecules. 2005;6:653–62.

Gojny FH, Schulte K. Functionalisation effect on the thermo-mechanical behaviour of multi-wall carbon nanotube/epoxy-composites. Compos Sci Technol. 2004;64:2303–8.

Li J, Chen P, Ma Z, et al. Reaction kinetics and thermal properties of cyanate ester-cured epoxy resin with phenolphthalein poly (ether ketone). J Appl Polym Sci. 2009;111:2590–6.

Wen QZ, Yu C, Zhu JH, et al. Studies on curing kinetics parameter of TDI-PPG-MOCA polyurethane by FTIR. Adv Mater Res. 2011;328:966–9.

Wu YG, Luo YJ, Ge Z, et al. FT-IR study on the curing reaction of isophorone diisocyanate with the glycidyl azide polymer and its prepolymer with nitrocellose. Chin J Explos Propellants. 2013;1:43–6.

Shen FF, Tanver A, Luo YJ. FT-IR study on the catalytic reaction kinetics of glycidyl azide polymer with N100. Chin J Explos Propellants. 2014;37:14–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, Xl., Fan, Xz. Curing reaction kinetics of HTPE polymer studied by simultaneous rheometry and FTIR measurements. J Therm Anal Calorim 125, 977–982 (2016). https://doi.org/10.1007/s10973-016-5485-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5485-8