Abstract

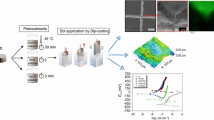

This paper describes a simple, facile, low-cost method of fabricating a wear-resistant surface on titanium alloy substrates by single-step anodization and modification with silicon dioxide particles. The method produced a TiO2–SiO2 composite surface with micro- to nanohierarchical structure, which became multifunctional after fluoroalkylsilane modification. The surface not only showed excellent superhydrophobicity [contact angles (CAs) > 150°, sliding angles (SAs) ≤ 8°] but also exhibited better repellency of complex whole blood (CAs = 153° ± 2°, SAs = 9°). Furthermore, the wear resistance of the surface was investigated by sandpaper abrasion test. The results showed that the mechanical wear resistance of the TiO2–SiO2 composite surface was more than three times that of the surface prepared only by the electrochemical technique, and the surface still maintained the capacity of hydrophobicity even after 33.6 m of wear under conditions of 3400 Pa and 360# sandpaper. The method mentioned in this paper could be a candidate for the production of abrasion-resistant and super-repellent titanium alloy.

Graphical Abstract

Similar content being viewed by others

References

Fürstner R, Barthlott W, Neinhuis C, Walzel P (2005) Wetting and self-cleaning properties of artificial superhydrophobic surfaces. Langmuir 21(3):956–961

Vakarelski IU, Patankar NA, Marston JO, Chan DY, Thoroddsen ST (2012) Stabilization of Leidenfrost vapour layer by textured superhydrophobic surfaces. Nature 489(7415):274–277

Boinovich LB, Emelyanenko AM (2013) Anti-icing potential of superhydrophobic coatings. Mendeleev Commun 23(1):3–10

Shen Y, Tao H, Chen S, Zhu L, Wang T, Tao J (2015) Icephobic/anti-icing potential of superhydrophobic Ti6Al4V surfaces with hierarchical textures. RSC Adv 5(3):1666–1672

Kota AK, Choi W, Tuteja A (2013) Superomniphobic surfaces: design and durability. MRS Bull 38(05):383–390

Ou J, Hu W, Liu S, Xue M, Wang F, Li W (2013) Superoleophobic textured copper surfaces fabricated by chemical etching/oxidation and surface fluorination. ACS Appl Mater Interfaces 5(20):10035–10041

Xue C-H, Li Y-R, Zhang P, Ma J-Z, Jia S-T (2014) Washable and wear-resistant superhydrophobic surfaces with self-cleaning property by chemical etching of fibers and hydrophobization. ACS Appl Mater Interfaces 6(13):10153–10161

Wang F, Luo H, Wang Q, Wang J, Xu J (2009) Preparation of superhydrophobic polymeric film on aluminum plates by electrochemical polymerization. Molecules 14(11):4737–4746

Wang D, Wang X, Liu X, Zhou F (2010) Engineering a titanium surface with controllable oleophobicity and switchable oil adhesion. J Phys Chem C 114(21):9938–9944

Li H, Liao J, Du Y, You T, Liao W, Wen L (2013) Magnetic-field-induced deposition to fabricate multifunctional nanostructured Co, Ni, and CoNi alloy films as catalysts, ferromagnetic and superhydrophobic materials. Chem Commun 49(17):1768–1770

Qian B, Shen Z (2005) Fabrication of superhydrophobic surfaces by dislocation-selective chemical etching on aluminum, copper, and zinc substrates. Langmuir 21(20):9007–9009

Huang Z, Geyer N, Werner P, De Boor J, Gösele U (2011) Metal-assisted chemical etching of silicon: a review. Adv Mater 23(2):285–308

Cui H, Yang G, Sun Y, Wang C (2010) Reversible ultraviolet light-manipulated superhydrophobic-to-superhydrophilic transition on a tubular SiC nanostructure film. Appl Phys Lett 97(18):183112

Yf G (2014) SiO2/TiO2 composite aerogels: preparation via ambient pressure drying and photocatalytic performance. Ceram Int 40:13781–13786

Hahn R, Macak J, Schmuki P (2007) Rapid anodic growth of TiO2 and WO3 nanotubes in fluoride free electrolytes. Electrochem Commun 9(5):947–952

Berger S, Macak JM, Kunze J, Schmuki P (2008) High-efficiency conversion of sputtered Ti thin films into TiO2 nanotubular layers. Electrochem Solid-State Lett 11(7):C37–C40

Liang J, Liu K, Wang D, Li H, Li P, Li S, Su S, Xu S, Luo Y (2015) Facile fabrication of superhydrophilic/superhydrophobic surface on titanium substrate by single-step anodization and fluorination. Appl Surf Sci 338:126–136

Barthwal S, Kim YS, Lim S-H (2013) Fabrication of amphiphobic surface by using titanium anodization for large-area three-dimensional substrates. J Colloid Interface Sci 400:123–129

Lu Y, Song J, Liu X, Xu W, Xing Y, Wei Z (2012) Preparation of superoleophobic and superhydrophobic titanium surfaces via an environmentally friendly electrochemical etching method. ACS Sustain Chem Eng 1(1):102–109

Huang Q, Yang Y, Hu R, Lin C, Sun L, Vogler EA (2015) Reduced platelet adhesion and improved corrosion resistance of superhydrophobic TiO2-nanotube-coated 316L stainless steel. Colloids Surf B 125:134–141

Ebert D, Bhushan B (2012) Transparent, superhydrophobic, and wear-resistant coatings on glass and polymer substrates using SiO2, ZnO, and ITO nanoparticles. Langmuir 28(31):11391–11399

Tang Y, Yang J, Yin L, Chen B, Tang H, Liu C, Li C (2014) Fabrication of superhydrophobic polyurethane/MoS2 nanocomposite coatings with wear-resistance. Colloids Surf A 459:261–266

Su C, Xu Y, Gong F, Wang F, Li C (2010) The abrasion resistance of a superhydrophobic surface comprised of polyurethane elastomer. Soft Matter 6(24):6068–6071

Zhu Q, Chu Y, Wang Z, Chen N, Lin L, Liu F, Pan Q (2013) Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material. J Mater Chem A 1(17):5386–5393

Kartini I, Santosa SJ, Febriyanti E, Nugroho OR, Yu H, Wang L (2014) Hybrid assembly of nanosol titania and dodecylamine for superhydrophobic self-cleaning glass. J Nanopart Res 16(7):1–14

Mittal KL (2007) Silanes and other coupling agents, vol 4. CRC Press, Florida

Min K, Gao H, Matyjaszewski K (2005) Preparation of homopolymers and block copolymers in miniemulsion by ATRP using activators generated by electron transfer (AGET). J Am Chem Soc 127(11):3825–3830

Lee H, Scherer NF, Messersmith PB (2006) Single-molecule mechanics of mussel adhesion. Proc Natl Acad Sci U S A 103(35):12999–13003. doi:10.1073/pnas.0605552103

Kang SM, You I, Cho WK, Shon HK, Lee TG, Choi IS, Karp JM, Lee H (2010) One-step modification of superhydrophobic surfaces by a mussel-inspired polymer coating. Angew Chem 49(49):9401–9404. doi:10.1002/anie.201004693

Lian F, Zhang HC, Pang LY, Zhu HB (2012) Effects of surface film on superhydrophobic characteristics of Ti6Al4V with dotted matrix structure. Rare Met Mater Eng 41(4):612–616

Zhang L, Wu J, Wang Y, Long Y, Zhao N, Xu J (2012) Combination of bioinspiration: a general route to superhydrophobic particles. J Am Chem Soc 134(24):9879–9881

Marmur A, Bittoun E (2009) When Wenzel and Cassie are right: reconciling local and global considerations. Langmuir 25(3):1277–1281

Verplanck N, Coffinier Y, Thomy V, Boukherroub R (2007) Wettability switching techniques on superhydrophobic surfaces. Nanoscale Res Lett 2(12):577–596

Sun Y, Wang L, Gao Y, Guo D (2015) Preparation of stable superamphiphobic surfaces on Ti-6Al-4V substrates by one-step anodization. Appl Surf Sci 324:825–830

Acknowledgments

This work was financially supported by the National Basic Research Program of China (2012CB934100).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Q., Tang, F., Wang, C. et al. Facile fabrication of wear-resistant multifunctional surfaces on titanium alloy substrate by one-step anodization and modification with silicon dioxide nanoparticles. J Sol-Gel Sci Technol 80, 318–325 (2016). https://doi.org/10.1007/s10971-016-4088-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4088-y