Abstract

Accurate, low-level measurement of 226Ra in high volume water samples requires rapid pre-concentration and robust separation techniques prior to measurement in order to comply with discharge limits and drinking water regulations. This study characterises the behaviour of 226Ra and interfering elements on recently developed TK100 (Triskem International) extraction chromatography resin. Distribution coefficients over a range of acid concentrations are given, along with an optimised procedure that shows rapid pre-concentration and separation of 226Ra on TK100 resin is achievable for high volume (1 L) water samples without the need for sample pre-treatment.

Similar content being viewed by others

Introduction

226Ra (half-life 1600 (7) years [1]) is a naturally occurring radionuclide in the 238U decay series, with additional inputs into the environment as a result of mining, the extraction of fossil fuels and chemical processing. It is the most significant contributor to occupational radiological doses arising from industrial naturally occurring radioactive material (NORM) sources [2–5]. 226Ra decays by alpha emission, with a maximum decay energy of 4.79 MeV (94.0%) [1], and gamma emission with a maximum decay energy of 186.2 (13) keV (32.8%). 226Ra is measurable by alpha spectrometry [6–8], liquid scintillation counting [9–11], gamma spectrometry [12–14] and inductively coupled plasma mass spectrometry (ICP-MS) [15–23]. Measurement of 226Ra is important with regards to drinking water quality as well as environmental monitoring around nuclear and industrial sites, including mining and processing sites for coal, phosphogypsum and uranium. The measurement of 226Ra is also important for radiological protection in areas of high radon concentration and more recently, in the measurement of produced and discharged waters following hydraulic fracturing (fracking) of shale gas resources [24, 25]. Consequently, there is a growing need to develop methods that can achieve rapid and accurate measurement of 226Ra in water samples from a variety of sources.

The World Health Organisation proposes a guideline value of 1 Bq L−1 for 226Ra in drinking water [26], whilst Canada specifies a Maximum Acceptable Concentration of 0.5 Bq L−1 [27]. The European Union gives an indicative annual dose of 0.1 mSv [4], and goes on to state that the method used for analysis must be capable of determining an activity concentration of 0.04 Bq L−1. In the United States, the Maximum Contaminant Level is set at 5 pCi L−1 (0.19 Bq L−1) for 226Ra and 228Ra combined [28]. Different limits apply to industrial discharges. The Environmental Permitting Regulations for England and Wales [3] stipulate maximum activity concentrations for discharging aqueous liquids to environmental water courses; in the case of 226Ra, the limit is 0.01 Bq L−1.

For all applications, separation and pre-concentration of 226Ra is required prior to measurement. A number of chemical separation techniques have been successfully applied to 226Ra separation, including anion and cation exchange, diffusive gradients in thin films (DGT), adsorption onto manganese dioxide resin, and extraction chromatography using strontium resin [19, 29–32]. A recently developed extraction chromatography resin is TK100 (Triskem International), which was developed primarily for extraction of 90Sr from high volume water samples [33]. The advantage of the resin is that 90Sr shows good retention when water is directly loaded at pH 2–8, compared to Sr-resin (Triskem International) where moderate to high acid concentrations are required prior to loading [34]. The TK100 resin consists of the same Sr-resin crown ether group that shows high selectivity for Sr (Di-t-butyl dicyclohexyl-18-crown-6), with the addition of Di(2-tethyl-hexyl) phosphoric acid (HDEHP). Whilst the resin has been characterised for 90Sr and several other radionuclides and stable elements [33–35], there is no information on the behaviour of 226Ra on TK100 resin. The potential to directly load high volume water samples with minimal prior treatment will offer a significant reduction in procedural time compared to alternative separation techniques. The resulting higher sample throughput would be highly advantageous in several applications including, routine monitoring of drinking water samples and compliance testing of discharges against regulatory targets.

The aim of this work is to further characterise TK100 resin, focusing on 226Ra in high volume (1 L) water samples. The behaviour of 226Ra and multiple other elements are investigated, as is the effect of high salt loadings on the resin performance. The ultimate aim is to produce a separation scheme that is applicable to both radiometric and mass spectrometric measurements of environmental or industrial water samples.

Experimental

Reagents and materials

Standard element solutions (Ba, Ca, Ce, Cs, Eu, La, Mg, Nb, Sr, Th, U, Y, and Zr) at starting concentrations from 1000-10,000 mg L−1 were purchased from Fluka Analytical and Fisher Scientific. NaCl, KCl, FeCl2, MgCl2, CaCl2, SrCl2 and BaCl2 for simulated fracking waters were all provided by Fisher Scientific. Nitric and hydrochloric acids were purchased from Fisher Scientific (Trace Analysis Grade). Standards and acids were diluted with ultrapure water (18 MΩ, <5 μg L−1 Total Organic Carbon) from an ELGA purelabflex water purification system. 226Ra standards were prepared at NPL over an activity concentration range of 0.01–10 Bq g−1. TK100 resin (100–150 μm particle size) was provided by Triskem International.

Instrumentation

All measurements were performed using an Agilent 8800 triple quadrupole inductively coupled plasma mass spectrometer (ICP-QQQ-MS). The instrument is equipped with a collision-reaction cell positioned between two quadrupole mass filters, and was run in Single Quad mode (i.e. only one quadrupole mass filter operating) throughout. The instrument was fitted with a quartz double-pass spray chamber, MicroMist nebuliser, quartz torch (2.5 mm internal diameter), and nickel sample and skimmer cones. The instrument was tuned daily using a mixed 1 μg L−1 standard solution, and then tuned further for 226Ra. The sensitivity was on the order of 330 counts per second for a 1 ng L−1 (36.6 mBq g−1) solution, with a detection limit of ~0.1 ng L−1 (0.4 mBq g−1). A more detailed account of the performance of ICP-QQQ-MS for 226Ra measurement is described elsewhere [36].

Calculation of distribution coefficients

The distribution coefficients for 226Ra and other group 2 elements for solutions at a range of acid concentrations (0.01–10 M HCl or HNO3) were calculated using Eq. 1:

where CPSi and CPSf are the initial and final counts per second measured by ICP-QQQ-MS for the element of interest, V is the volume of solution (mL), and m is the mass of the resin (g).

A 2 mL mixed stable element solution was prepared at a concentration of 100 μg L−1 for each element. The solution was evaporated to dryness, before being made up in 2 mL of HCl or HNO3 over a concentration range of 0.01–10 M. Prior to the addition of TK100 resin, a 0.5 mL aliquot was taken for ICP-MS measurement of the initial counts per second (CPSi). One hundred milligrams of TK100 resin was then added to each sample and left overnight. The sample was then filtered through a Whatman 0.45 μm filter paper, a 0.5 mL aliquot was taken for ICP-MS measurement of the final counts per second (CPSf). During analysis, 232Th was run as an internal standard in the instruments dedicated internal standard line to correct for instrument drift.

To assess the impact of high salt loading on resin performance, a range of single element solutions associated with fracking waters were prepared based on information from Maxwell et al. (Table 1) [25]. The solutions were prepared in 0.01 M HNO3 and the K d values were calculated and compared to the results for non-salt loaded solutions.

Elution profiles for high volume water samples

Optimal load and elution conditions determined from the K d results were applied to blank water samples spiked with the range of elements listed previously. A 2 mL TK100 column (4 cm length × 0.5 cm diameter) was conditioned with 10 mL of the same acid concentration as the load solution, with no additional clean-up steps. A mixed stable element solution (1 L total volume at a concentration of 100 μg L−1) was loaded onto the column, followed by an elution volume of 10 mL. The load solution was split into 20 × 50 mL fractions, and the elution fraction split into 10 × 1 mL fractions to generate sample load and elution profiles, respectively. For all the fractions, a 1 mL aliquot was taken and diluted to 10 mL with 2% (v/v) HNO3 for ICP-QQQ-MS measurement to calculate the distribution coefficient and recovery of each element. The separation was carried out using a vacuum box at a flow rate of approximately 2 mL/min, with the procedure for a batch of 12 samples completed in approximately 8 h.

Results and discussion

Distribution coefficients

Radium is well retained on the resin at pH 2, with K d values of 5.8 × 102 and 7.7 × 102 for HCl and HNO3, respectively (Fig. 1). This compares to values of 5.8 × 102 and 3.9 × 102 for Sr. The distribution coefficient reduces significantly from 0.01 to 0.1 M for both HCl and HNO3; therefore, it is advised that the solution is kept at pH 2 prior to loading to avoid Ra losses. Nevertheless, the results confirm that direct loading of water samples acidified to pH 2 is applicable with respect to 226Ra analysis. Elution is achievable from 1 to 10 M HNO3 or HCl, with a maximum K d of 2.4 × 101 over this concentration range. The retention of Ra on TK100 resin is a noticeable improvement compared to Sr-resin, where Ra is not retained under any conditions; this may offer advantages where both strontium and radium isotope measurements are required from the same sample.

Calcium showed no retention on the resin under any of the conditions tested, which is beneficial for alpha spectrometry measurements where high Ca content may impact on the source preparation and reduce the resolution of the alpha spectrum, increasing the measurement uncertainty and producing unresolvable peaks. Barium and strontium performed similarly to Ra, in good agreement with the manufacturer’s claim that both elements would be retained at pH 2 and eluted in 8 M HNO3 and 2–3 M HCl for Ba and Sr, respectively [35]. As the acid concentration increases from 0.01 to 0.1 M, the K d for Ra reduces by a factor of 56, which is similar for both HCl and HNO3. This compares to factors of 19 for Sr and 8 for Ba. Therefore, loading at pH 1 rather than pH 2 will adversely impact the retention of all these elements, with the effect most significant for Ra. The results suggest that that separation of Ra from Sr and Ba using TK100 resin would be challenging. For high volume water samples, loading conditions of 0.01 M HNO3/HCl and Ra elution in 1 M HNO3 and HCl for high volume water samples are investigated below.

Elution profiles for high volume water samples

The results for a multi-element solution showed good agreement between this study and results from Triskem regarding the behaviour of Sr, with breakthrough of Sr above a load volume of approximately 500 mL [35] (Fig. 2). Under both 0.01 M HCl and HNO3 loading conditions, breakthrough was <1% after a volume of 500 mL, but increased steadily at higher volumes, with loss of 18 and 15% after loading in 1 L 0.01 M HNO3 and HCl, respectively. Magnesium and calcium were not retained in the load solution.

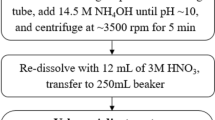

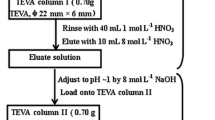

Barium was well retained in the load solution, and both Ba and Sr were eluted in 1 M HCl or 1 M HNO3 along with 226Ra. This is an important consideration for ICP-MS applications, where polyatomic 138Ba88Sr can overlap with 226Ra [23]. Results from Triskem suggest that Sr is retained in 8–10 M HNO3, and that Ba is retained in 1 M HNO3 if the elution volumes are carefully controlled. By comparison, 226Ra is eluted in 1–10 M for both acids tested. To improve separation, a Sr-resin (Triskem International) column could be connected in tandem to a TK100 column following the sample load. If the elution conditions are changed to 3 M HNO3, then 226Ra, Ba and Sr will be eluted from the TK100 column; however, only Ra will be eluted from the Sr-resin column. The results in Fig. 2 also suggest that Sr, Ba and Ra recovery could be improved by increasing the elution volume from 10 to 20 mL.

Of the elements investigated, U, Th, Y, Zr, Nb, La, Ce and Eu, were also retained in the load solution, whilst Cs was not. Of these, U, Th, Y, Zr, and Nb were also well retained in 1 M HNO3 or 1 M HCl, therefore separation of 226Ra from naturally occurring radionuclides and other elements of importance to the nuclear industry is achievable using TK100. By comparison, La, Ce and Eu were detected in both eluents tested (not shown in Fig. 2), with higher recoveries in 1 M HCl (77–81%) compared to 1 M HNO3 (23–37%). This must be considered for ICP-MS procedures, where polyatomic 87Sr139La and 86Sr140Ce overlap with 226Ra. The formation of these interferences can be minimised by eluting in HNO3 rather than HCl, due to the lower La, Ce and Eu recovery, whilst Sr can be removed through the use of Sr-resin as previously described. Results from Triskem show that Pb is well retained when loaded at pH 2, but can be eluted along with U in 6 M HCl [35]. 226Ra is also eluted under these conditions, therefore separation of 226Ra from Pb and U is achievable by washing the column with 1 M HNO3 or HCl, followed by 6 M HCl to elute U.

Impact of fracking waters on TK100 performance

As well as elevated activities of 226Ra, waters from fracking sources can contain high concentrations (g L−1) of multiple elements in the form of salts (including chlorides of Na, Ca, Mg, Sr and Ba) [25], which can impact the performance of chemical separation techniques. The performance of TK100 resin may be affected by the high matrix content associated with fracking waters, necessitating additional separation prior to sample loading. TK100 resin has been tested for Sr at pH 7 in the presence of 11,500 mg L−1 Na, 400 mg L−1 K, 1300 mg L−1 Mg and 500 mg L−1 Ca, with good retention of Sr under all conditions [33, 35]. Figure 3 shows the impact of a range of concentrations of Na, K, Fe, Mg, Ca, Sr and Ba chlorides (Table 1) on the retention of 226Ra at pH 2 (0.01 M HNO3). All of the salts tested adversely affect Ra retention on the resin, with SrCl2 and BaCl2 having the most significant impact; the K d for Ra reduced at concentrations of 5 g L−1 SrCl2 and 10 g L−1 BaCl2. At the highest concentration of each element tested, the K d for Ra ranged from <1 (1000 g L−1 BaCl2) to 425 (100 g L−1 MgCl2). Therefore, the sample matrix significantly impacts the performance of TK100 resin with regards to 226Ra, in agreement with the findings of Nelson et al. for other separation procedures [24].

Conclusion

Rapid and accurate assessment of 226Ra is important with regards to drinking water quality, environmental monitoring and in measurement of produced waters from industrial processes including fracking. Radiometric and mass spectrometric determination of 226Ra requires pre-concentration and separation from interfering stable and radioactive isotopes prior to measurement. The application of recently developed TK100 extraction chromatography resin for 226Ra has been investigated for high volume water samples. The distribution coefficients were determined for 226Ra and interfering elements in HNO3 and HCl media, with the optimal conditions tested for 1 L water samples. Loading conditions of 0.01 M HNO3 or HCl were found to be suitable for retention of 226Ra, suggesting that samples can be loaded onto the resin with minimal sample pre-treatment, whilst elution is achievable in 1–10 M HNO3 or HCl. The high salt concentration of multiple elements associated with fracking waters adversely affects the performance of TK100 resin with Sr and Ba having the most significant impact; therefore, chemical separation prior to measurement must be considered for this application. Overall, TK100 resin provides a novel and rapid approach that is applicable as a single-stage or as part of a multi-stage pre-concentration and separation procedure for 226Ra in high volume water samples that can be used in conjunction with radiometric or mass spectrometric measurement.

References

Bé MM, Christé V, Dulieu C, Browne E, Chechev V, Kuzmenko N, Kondev F, Luca A, Galán M, Pearce A, Huang X (2008) Table of radionuclides, vol 4 (A = 133 to 252). BIPM, Sèvres

International Atomic Energy Agency (IAEA) (2010) Analytical methodology for the determination of radium isotopes in environmental samples. IAEA Analytical Quality in Nuclear Applications Series No. 19

EPR (The Environmental Permitting (England and Wales) Regulations) (2010) Statutory Instruments 2043

Council Directive 2013/51/Euratom (2013) laying down requirements for the protection of the health of the general public with regard to radioactive substances in water intended for human consumption

Read D, Read G, Thorne M (2013) Background in the context of land contaminated with naturally occurring radioactive material. J Radiol Prot 33:367–380

Jia G, Torri G, Innocenzi P, Ocone R, Di Lullo A (2005) Determination of radium isotope in mineral water12 samples by α spectrometry. Int Congr Sci 1276:412–414

Maxwell SL (2006) Rapid method for 226Ra and 228Ra analysis in water samples. J Radioanal Nucl Chem 270:651–655

Bergamini G, Taddei MHT, Rosa MML, Ferreira MT, Cheberle LTV, dos Santos SMC, Mariano NA, Ramos ECT (2016) Determination of 226Ra in drinking water samples by alpha spectrometry. J Radioanal Nucl Chem 307:829–834

Yoon YY, Cho SY, Lee KY, Ko KS, Ha K (2013) Radiochemical determination of uranium and radium isotope in natural water using liquid scintillation counter. J Radioanal Nucl Chem 296:397–402

Godoy JM, Vianna LM, Godoy MLDP, Almeida AC (2016) Determination of 226Ra in produced water by liquid scintillation counting. J Environ Radioact 160:25–27

Kim H, Jung Y, Ji Y-Y, Lim J-M, Chung KH (2016) Validation of a procedure for the analysis of 226Ra in naturally occurring radioactive materials using a liquid scintillation counter. J Environ Radioact (In Press)

van Beek P, Souhaut M, Reyss J-L (2010) Measuring the radium quartet (228Ra, 226Ra, 224Ra, 223Ra) in seawater samples using gamma spectrometry. J Environ Radioact 101:521–529

Diab H, Abdellah WM (2013) Validation of 226Ra and 228Ra measurements in water samples using gamma spectrometric analysis. J Water Res Prot 5:53–57

Mauring A, Gäfvert T, Aleksandersen TB (2014) Implications for analysis of 226Ra in low-level gamma spectrometry laboratory due to variations in radon background levels. Appl Radiat Isot 94:54–59

Epov VN, Larivière D, Evans RD, Li C, Cornett RJ (2003) Direct determination of 226Ra in environmental matrices using collision cell inductively coupled plasma mass-spectrometry. J Radioanal Nucl Chem 256(1):53–60

Larivière D, Epov VN, Reiber KM, Cornett RJ, Evans RD (2004) Micro-extraction procedures for the determination of Ra-226 in well waters by SF-ICP-MS. Anal Chim Acta 528:175–182

Benkhedda K, Larivière D, Scott S, Evans D (2005) Hyphenation of flow injection on-line preconcentration ICP-MS for the rapid determination of 226Ra in natural waters. J Anal At Spectrom 20:523–528

Koornneef JM, Stracke A, Aciego S, Reubi O, Bourdon B (2010) A new method for U-Th-Pa-Ra separation and accurate measurement of 234U-230Th-231Pa-226Ra disequilibria in volcanic rocks by MC-ICPMS. Chem Geol 277:30–41

Sharabi G, Lazar B, Kolodny Y, Teplyakov N, Halicz L (2010) High precision determination of 228Ra and 228Ra/226Ra isotope ratio in natural waters by MC-ICPMS. Int J Mass Spectrom 294:112–115

Tsai T-L, Lin C-C, Wang T-Y (2010) Application of ICP-QMS for the determination of ultratrace-levels of 226Ra in geothermal water and sediment samples. J Radioanal Nucl Chem 286:145–154

Hsieh Y-T, Henderson GM (2011) Precise measurement of 228Ra/226Ra ratios and Ra concentrations in seawater samples by multi-collector ICP mass spectrometry. J Anal At Spectrom 26:1338–1346

Copia L, Nisi S, Plastino W, Ciarletti M, Povinec P (2015) Low-level 226Ra determination in groundwater by SF-ICP-MS: optimization of separation and pre-concentration methods. J Anal Sci Technol 6:22

Zhang T, Bain DJ, Hammack RW, Visic RD (2015) Analysis of Radium-226 in high salinity wastewater from unconventional gas extraction by Inductively Coupled Plasma-Mass Spectrometry (ICP-MS). Environ Sci Technol 49:2969–2976

Nelson AW, May D, Knight AW, Eitrheim ES, Mehrhoff M, Shannon R, Litman R, Schultz MK (2014) Matrix complications in the determination of radium levels in hydraulic fracturing flowback water from Marcellus Shale. Environ Sci Technol Lett 1:204–208

Maxwell SL, Culligan BK, Warren RA, McAlister DR (2016) Rapid method for the determination of 226Ra in hydraulic fracturing wastewater samples. J Radioanal Nucl Chem 309:1333–1340

World Health Organisation (2011) Guidelines for drinking-water quality, Fourth edn. ISBN 978 92 4 154815 1

Health Canada (2009) Guidelines for Canadian Drinking Water Quality: Guideline Technical Document—Radiological Parameters. Radiation Protection Bureau, Healthy Environments and Consumer Safety Branch, Health Canada, Ottawa, Ontario. (Catalogue No. H128-1/10-614E-PDF)

Environment Protection Agency (2000) National Primary Drinking Water Regulations; Radionuclides; Final Rule (Part II), 40 CFR Parts 9, 141, and 142

Varga Z (2007) Preparation and characterisation of manganese dioxide impregnated resin for radionuclide pre-concentration. Appl Radiat Isot 65:1095–1100

Amr MA, Al-Meer SH, Taha MA, Othman ZA, Alghoul MM (2011) Ultratrace determination of Radium-226 in mineral water by collision/reaction cell inductively coupled plasma mass spectrometry. Int J Phys Sci 1:11–18

Leermakers M, Gao Y, Navez J, Poffin A, Croes K, Baeyens W (2009) Radium analysis by sector field ICP-MS in combination with the Diffusive Gradients in Thin Films (DGT) technique. J Anal Atom Spectrom 24:1115–1117

Gao Y, Baeyens W, De Galan S, Poffijn A, Leermakers M (2000) Mobility of radium and trace metals in sediments of the Winterbeck: application of sequential extraction and DGT techniques. Environ Pollut 158:2439–2445

Surman JJ, Pates JM, Zhang H, Happel S (2014) Development and characterisation of a new Sr selective resin for the rapid determination of 90Sr in environmental water samples. Talanta 129:623–628

Horwitz P, Chiarizia R, Dietz M (1992) Solvent extraction and ion exchange 10(2): 310

Triskem International Product Sheet TK100/TK101 resins. http://triskem-international.com/iso_album/ft_resine_tk100_1_en_141219.pdf. Accessed 18 Oct 2016

Van Es EM, Russell BC, Ivanov P, Read D (2017) Development of a method for rapid analysis of Ra-226 in groundwater and discharge water samples by ICP-QQQ-MS. Appl Radiat Isot (submitted for review)

Acknowledgements

This work was supported by the National Measurement System Programmes Unit of the UK’s Department for Business, Energy and Industrial Strategy. We are grateful to the National Physical Laboratory for funding the PhD studentship for E. M. van Es.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

van Es, E.M., Russell, B.C., Ivanov, P. et al. The behaviour of 226Ra in high-volume environmental water samples on TK100 resin. J Radioanal Nucl Chem 312, 105–110 (2017). https://doi.org/10.1007/s10967-017-5203-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-017-5203-4