Abstract

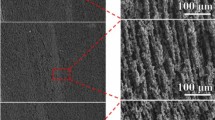

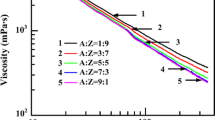

Porous WS2 scaffolds with aligned lamellar pore were fabricated by freeze casting, and the pore morphology and size can be well controlled by adjusting the processing parameters during freeze casting process. The results indicated that the porosity and the compressive strength of porous WS2 were greatly affected by the concentration of gelatin. As the gelatin addition increased from 1 to 5 wt%, the porosity of porous WS2 scaffolds with initial solid content of 3 vol% decreased from 95.12 to 90.23%, and their compressive strength increased from 0.22 to 1.16 MPa. Moreover, the lamellar spacing and wall thickness could be tailored from 90 to 320 and 5 to 30 μm respectively by changing the cooling temperature. And the compressive strength of scaffolds has a slight increase with the decreases of cooling temperature. The porous WS2 scaffold with fine aligned lamellar structure and proper compressive strength are expected to be used for scaffold materials.

Similar content being viewed by others

References

R.P. Liu, T.T. Xu, C.A. Wang, Ceram. Int. 42, 2907 (2016)

D.S. Kim, C. Baek, H.J. Ma, D.K. Kim, Ceram. Int. 42, 7141 (2016)

Y. Zhang, K.C. Zhou, J. Zeng, D. Zhang, Adv. Appl. Ceram. 112, 405 (2013)

B. Ho Yoon, W.Y. Choi, H.E. Kim, J.H. Kimb, Y.H. Kohb, Scripta Mater. 58, 537 (2008)

F. Wang, D.X. Yao, Y.F. Xia, K.H Zuo, J.Q. Xu, Y.P. Zeng, Ceram. Int. 42, 4526 (2016)

U.G.K. Wegst, M. Schecter, A.E. Donius, P.M. Hunger, Philos. Trans. R. Soc. A 368, 2099 (2010)

T.T. Xu, C.A. Wang, Mater. Design. 91, 242 (2016)

D.Y. Li, M.S. Li, J. Porous. Mater. 19, 345 (2012)

S. Deville, E. Maire, A. Lasalle, A. Bogner, C. Gauthier, J. Leloup, C. Guizard, J. Am. Ceram. Soc. 93, 2507 (2010)

A. Shaga, P. Shen, R.F. Guo, Q.C. Jiang, Ceram. Int. 42, 9653 (2016)

Y. Zhang, K.H. Zuo, Y.P. Zeng, Ceram. Int. 35, 2151 (2009)

F. Ye, J.Y. Zhang, L.M. Liu, H.J. Zhan, Mater. Sci. Eng. A 528, 1421 (2011)

J.S. Wu, X.L. Liu, L.M. Yan, L. Zhang, Mater. Lett. (2017) doi:10.1016/j.matlet.2017.03.031

N. Arabi, A. Zamanian, Biotechnol. Appl. Biochem. 5, 573 (2013)

L. Qian, H.F. Zhang, J. Chem. Technol. Biotechnol. 86, 172 (2011)

B.Y. Han, R.B. Zhang, D.N. Fang, J. Porous. Mater. 23, 563 (2016)

S.J. Dong, W.Z. Zhu, X.L. Gao, Z. Wang, L.Y. Wang, X.Y. Wang, C.J. Gao, Chem. Eng. J. 295, 530 (2016)

D.E.L. Anguloa, P.J.D.A. Sobrala, Mater. Res. 19, 839 (2016)

Y.J. Fu, P. Shen, Z.J. Hu, C. Sun, R.F. Guo, Q.C. Jiang, J. Porous. Mater. 23, 539 (2016)

D. Yao, Y. Xia, Y.P. Zeng, K. Zuo, D. Jiang, Mater. Lett. 68, 75 (2012)

S. Deille, E. Saiz, A.P. Tomsia, Biomaterials 27, 5480 (2006)

H.X. Zhang, P.D.A. Nunes, M. Wilhelm, K. Rezwan, J. Eur. Ceram. Soc. 36, 51 (2016)

S. Deville, E. Saiz, A.P. Tomsia, Acta Mater. 55, 1965 (2007)

Acknowledgements

This research was supported by the National Nature Science Foundation of China (Nos. 51674304 and 51604305), China Postdoctoral Science Foundation (2016M592445) and the Postdoctoral Science Foundation of Central South University.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, J., Luo, B., Liu, X. et al. Control of the structure and mechanical property of porous WS2 scaffold during freeze casting. J Porous Mater 25, 37–43 (2018). https://doi.org/10.1007/s10934-017-0418-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-017-0418-x