Abstract

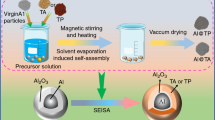

Silica-doped alumina aerogels offer the potential alternative to the applications as thermal insulators, catalysis, or catalytic support at elevated temperatures. However, the production process of silica-doped alumina aerogels was complicated and time-consuming. We developed a one-step precursor-to-aerogel method of silica-doped alumina aerogels with high specific surface area and thermal stability. Compared to conventional methods, the developed method reduced time and solvent waste of alumina-based aerogels production. Here, we investigated the alumina aerogels doped with silica to stabilize γ-phase at higher temperatures. XRD, FTIR, TEM, TG-DSC, and BET analysis results showed that silica stabilized the γ-Al2O3 at 1200 °C. The stabilization mechanism analysis showed that silica addition could significantly hinder the contact among alumina particles and the formation of necks in the sintering process, thereby retarding the transition of γ–θ phase and maintaining the high specific surface area at elevated temperatures. Silica and alumina particles formed mullite at 1200 °C, which could suppress α-phase transformation. In addition, silica-doped alumina aerogels exhibited the high specific surface area of 311 m2/g at 1000 °C and 146 m2/g at 1200 °C when the silica content was in the range of 10.6–13.1 wt%.

Similar content being viewed by others

References

M. Ozawa, J. Alloys Compd. 408–412, 1090–1095 (2006)

S.M. Jones, J. Sakamoto, Aerogels Handbook (Springer, Berlin, 2011), pp. 721–746

F.I. Hurwitz et al., J. Sol-Gel Sci. Technol. 64(2), 367–374 (2012)

F. He et al., J. Mater. Process. Technol. 209(3), 1621–1626 (2009)

S. Gutzov et al., J. Sol-Gel Sci. Technol. 70(3), 511–516 (2014)

P.B. Sarawade et al., Powder Technol. 197(3), 288–294 (2010)

J. Zhu, S. Guo, X. Li, RSC Adv. 5(125), 103656–103661 (2015)

H. Tatsuro et al., J. Non-Cryst. Solids 2001(291), 187–198 (2001)

L. Xu et al., Ceram. Int. 41(1), 437–442 (2015)

S.J. Juhl et al., J. Non-Cryst. Solids 426, 141–149 (2015)

X. Wu et al., Ceram. Int. 42(1), 874–882 (2016)

X. Wu et al., RSC Adv. 6(7), 5611–5620 (2016)

G. Zu et al., Chem. Mater. 26(19), 5761–5772 (2014)

J.F. Poco, J.H. Satcher Jr., L.W. Hrubesh, J. Non-Cryst. Solids 2001(285), 57–63 (2001)

G. Zu et al., Chem. Mater. 25(23), 4757–4764 (2013)

D.B. Mahadik et al., J. Supercrit. Fluids 107, 84–91 (2016)

A. Boumaza et al., J. Solid State Chem. 182(5), 1171–1176 (2009)

A.H. Munhoz Jr. et al., Advances in Science and Technology (Trans Tech Publications, Germany, 2010)

X. Zhang et al., J. Cryst. Growth 310(15), 3674–3679 (2008)

M.A. Saltzberg et al., J. Am. Ceram. Soc. 75(1), 89–95 (1992)

J.J. Liang et al., J. Mater. Sci. Technol. (2016). doi:10.1016/j.jmst.2016.02.012

M. Zawrah, E. Hamzawy, Ceram. Int. 28(2), 123–130 (2002)

S.-W. Kim, S. Iwamoto, M. Inoue, J. Porous Mater. 17(3), 377–385 (2009)

Y. Zhu et al., Ind. Eng. Chem. Res. 51(1), 255–261 (2012)

S.A. Dickie, A.J. McQuillan, Langmuir 20(26), 11630–11636 (2004)

J. Lee, S. Yu, J. Mater. Sci. 27(19), 5203–5208 (1992)

J. Wang et al., Microporous Mesoporous Mater. 218, 192–198 (2015)

G. Zu et al., J. Non-Cryst. Solids 357(15), 2903–2906 (2011)

T.F. Baumann et al., Chem. Mater. 17(2), 395–401 (2005)

D. Sarkar et al., Ceram. Int. 33(7), 1275–1282 (2007)

C.F. Diniz, K. Balzuweit, N.D.S. Mohallem, J. Nanopart. Res. 9(2), 293–300 (2006)

X. Chen et al., Appl. Catal. A 205(1), 159–172 (2001)

P. Alphonse, B. Faure, Microporous Mesoporous Mater. 196, 191–198 (2014)

N. Al-Yassir, R. Le Van Mao, Appl. Catal. A 317(2), 275–283 (2007)

T. Horiuchi et al., Catal. Lett. 58(2–3), 89–92 (1999)

F. Jian et al., Chin. J. Inorg. Chem. 25(10), 1758–1763 (2009)

A.P. Hynes, R.H. Doremus, J. Am. Ceram. Soc. 74(10), 2469–2475 (1991)

S.H. Hong, G.L. Messing, J. Am. Ceram. Soc. 81(5), 1269–1277 (1998)

Acknowledgements

The authors would like to acknowledge the financial support from the National Basic Research Program of China (973 Program, Grant No. 2015CB057502).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, J., Wang, Q., Wang, T. et al. Facile one-step precursor-to-aerogel synthesis of silica-doped alumina aerogels with high specific surface area at elevated temperatures. J Porous Mater 24, 889–897 (2017). https://doi.org/10.1007/s10934-016-0328-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-016-0328-3