Abstract

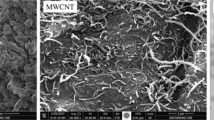

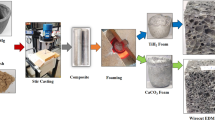

Carbon foam has been developed by templating method with phenolic resin and coal tar pitch as matrix precursor and polyurethane foam as a sacrificial template. For improving thermal and mechanical properties, aluminum (Al) powder with 2–8 wt% was added into the impregnation mixture. Carbonization at 1273 K in inert environment under the cover of coke breeze produced Al4C3 in situ and AlN by substitution reaction. Various thermal and mechanical tests showed a density of 0.50–0.58 g/cm3, open porosity of 64–68 %, thermal conductivity of 0.043–0.385 W/mK and a compressive strength of 17–32 MPa for the samples containing 0–6 wt% Al. Scanning electron microscope was used to evaluate the pore morphology, distribution of Al in the porous network and an approximate pore size distribution which came out to be in the range of 2–200 μm. X-ray mapping showed a homogeneous dispersion of Al with some agglomerates into the ball shape. Carbon foam with 8 wt% Al showed self-destruction in 14 days after 15 days of manufacturing. The destruction started from core and proceeded towards outer surface resulting in a core–shell effect. X-ray diffraction analysis confirmed the destruction due to the formation of Al4C3 and reaction with atmospheric moisture forming Al(OH)3. This property can be further explored to be applied in the field of composite tooling for advanced carbon fiber reinforced composites. The tool will lose strength after certain time, facilitating in easy removal from the complex shape composites.

Similar content being viewed by others

References

T. Suzuki, H. Umehara, Pitch-based carbon fiber microstructure and texture and compatibility with aluminum coated using chemical vapor deposition. Carbon 37, 47–59 (1999)

J.F. Silvain, C. Vincent, J.M. Heintz, N. Chandra, Novel processing and characterization of Cu/CNF nanocomposite for high thermal conductivity applications. Compos. Sci. Technol. 69, 2474–2484 (2009)

Y. Chen, B. Chen, X. Shi, H. Xu, Y. Hu, Y. Yuan, Preparation of pitch-based carbon foam using polyurethane foam template. Carbon 45, 2132–2134 (2007)

N.C. Gallego, J.W. Klett, Carbon foams for thermal management. Carbon 41, 1461–1466 (2003)

R. Mehta, D.P. Anderson, J.W. Hager, Graphitic open-celled carbon foams: processing and characterization. Carbon 41, 2174–2176 (2003)

J. Googin, J. Napier, M. Scrivner, Method for manufacturing foam carbon products, US Patent 3,345,440 (1967)

F.C. Cowlard, J.C. Lewis, Vitreous carbon: as new form of carbon. J. Mater. Sci. 2, 507–512 (1967)

R. D. Klett, High temperature insulating carbonaceous material, US Patent 3,914,392 (1975)

R.W. Pekala, R.W. Hopper, Low-density microcellular carbon foams. J. Mater. Sci. 22, 1840–1844 (1987)

J. Lee, K. Sohn, T. Hyeon, Fabrication of novel mesocellular carbon foams with uniform ultralarge mesopores. J. Am. Chem. Soc. 123, 5146–5147 (2001)

J. Klett, High thermal conductivity mesophase pitched-derived carbon foam, in Proceedings of the 1998 43rd International SAMPE Symposium and Exhibition, Part 1 (of 2) (Anaheim, CA 31 May–4 June, 1998)

C. Chen, E.B. Kennel, A.H. Stiller, P.G. Stansberry, J.W. Zondlo, Carbon foam derived from various precursors. Carbon 44, 1535–1543 (2006)

X.W. Wu, Y.G. Liu, M.H. Fang, L.F. Mei, B.C. Luo, Preparation and characterization of carbon foams derived from aluminosilicate and phenolic resin. Carbon 49, 1782–1786 (2011)

H.F. Xu, H.J. Zhang, Y.D. Huang, Y. Wang, Porous carbon/silica composite monoliths derived from resorcinol–formaldehyde/TEOS. J. Non-Cryst. Solids 356, 971–976 (2010)

Y.R. Liu, B.P. Lin, D. Li, X.Q. Zhang, Y. Sun, H. Yang, Magnetically-separable hierarchically porous carbon monoliths with partially graphitized structures as excellent adsorbents for dyes. J. Porous Mat. 21, 933–938 (2014)

S.W. Lei, Q.G. Guo, J.L. Shi, L. Liu, Preparation of phenolic-based carbon foam with controllable pore structure and high compressive strength. Carbon 48, 2644–2646 (2010)

Y.H. Yan, X.M. Shi, J.G. Liu, T. Zhao, Y.Z. Yu, Thermosetting resin system based on novolak and bismaleimide for resin-transfer molding. J. Appl. Polym. Sci. 83, 1651–1657 (2002)

M. Calvo, R. García, A. Arenillas, I. Suárez, S.R. Moinelo, Carbon foams from coals: a preliminary study. Fuel 84, 2184–2189 (2005)

S. Farhan, R.M. Wang, H. Jiang, N. Ul-Haq, Preparation and characterization of carbon foam derived from pitch and phenolic resin using a soft templating method. J. Anal. Appl. Pyrolysis 110, 229–234 (2014)

A.M. Druma, M.K. Alam, C. Druma, Analysis of thermal conduction in carbon foams. Int. J. Therm. Sci. 43, 689–695 (2004)

S.R. White, Y.K. Kim, Process-induced residual stress analysis of AS4/3501-6 composite material. Mech. Compos. Mater. Struct. 5, 153–186 (1998)

F.C. Campbell, Manufacturing processes for advanced composites (Elsevier Advanced Technology, Amsterdam, 2004)

A.M. Druma, M.K. Alam, M.S. Anghelescu, C. Druma, Three dimensional modeling of carbon foams, in ASME international mechanical engineering congress and exposition 2005 (Orlando, FL, 5–11 November, 2005)

A. Gardziella, L.A. Pilato, A. Knop, Phenolic resins: chemistry, application, standardization, safety and ecology, 2nd edn. (Springer, Berlin, 2000)

P. Byung-Dae, R. Bernard, Y.S. Kim, W.T. So, Effect of synthesis parameters on thermal behavior of phenol-formaldehyde resol resin. J. Appl. Polym. Sci. 83, 1415–1424 (2002)

J. Wang, H. Jiang, N. Jiang, Study on the pyrolysis of phenol-formaldehyde (PF) resin and modified PF resin. Thermochim. Acta 496, 136–142 (2009)

L.B. Manfredi, O. De La Osa, N. Galego Fernández, A. Vázquez, Structure-properties relationship for resols with different formaldehyde/phenol molar ratio. Polymer 40, 3867–3875 (1999)

J.T. Blucher, J. Dobranszky, U. Narusawa, Aluminium double composite structures reinforced with composite wires. Mater. Sci. Eng., A 387–389, 867–872 (2004)

E. Pippel, J. Woltersdorf, M. Doktor, J. Blucher, H.P. Degischer, Interlayer structure of carbon fibre reinforced aluminium wires. J. Mater. Sci. 35, 2279–2289 (2000)

R.Y. Lin, Interface evolution in aluminum matrix composites during fabrication. Key Eng. Mater. 104–107, 507–522 (1995)

M.H. Vidal-Sétif, M. Lancin, C. Marhic, R. Valle, J.L. Raviart, J.C. Daux, M. Rabinovitch, On the role of brittle interfacial phases on the mechanical properties of carbon fibre reinforced Al-based matrix composites. Mater. Sci. Eng., A 272, 321–333 (1999)

C. Qiu, R. Metselaar, Solubility of carbon in liquid Al and stability of Al4C3. J. Alloys Compd. 216, 55–60 (1994)

S.H. Li, C.G. Chao, Effects of carbon fiber/Al interface on mechanical properties of carbon-fiber-reinforced aluminum-matrix composites. Metall. Mater. Trans. A 35, 2153–2160 (2004)

H. Kwon, H. Kurita, M. Leparoux, A. Kawasaki, Carbon nanofiber reinforced aluminum matrix composite fabricated by combined process of spark plasma sintering and hot extrusion. J. Nanosci. Nanotechnol. 11, 4119–4126 (2011)

T.Y. Kosolapova, Carbides properties production and applications, 1st edn. (Plenum Press, New York, 1971)

J.K. Park, J.P. Lucas, Moisture effect on SiCP/6061 Al MMC: dissolution of interfacial Al4C3. Scr. Mater. 37, 511–516 (1997)

S. Meille, M. Lombardi, J. Chevalier, L. Montanaro, Mechanical properties of porous ceramics in compression: on the transition between elastic, brittle, and cellular behavior. J. Europ. Ceram. Soc. 32, 3959–3967 (2012)

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farhan, S., Wang, RM. Thermal, mechanical and self-destruction properties of aluminum reinforced carbon foam. J Porous Mater 22, 897–906 (2015). https://doi.org/10.1007/s10934-015-9963-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-015-9963-3