Abstract

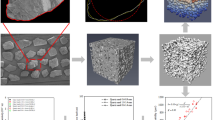

The three-dimensional void space structure generated by piling active carbon grains has a large impact on the filter operation, through the modification of the transport properties inside the bed. To gain insight into the relation between morphology and transport properties, the three-dimensional void space structure of activated carbon packed beds was studied by X-ray microtomography coupled with image analysis. Image analysis algorithms allowing the determination of the total void fraction, the void size distribution and the radial void fraction profiles were developed. This methodology was used to characterize the void space structure of two filters with the same length but different diameters, 15 and 28 mm. Commercial granular activated carbon with average particle size close to 1 mm was used. The comparison of the void size distributions indicated that void sizes are almost normally distributed around only one maximum for the large filter, while the distribution has a more complex shape in the small filter. The radial void fraction profiles showed an increase of the void fraction from the center of the filter to the wall accompanied with an oscillatory behaviour at the small scale. Power spectrum of radial profiles of the large filter shows a characteristic length matching well with the carbon particle size, indicating that the carbon grains are uniformly packed in the bed. In the small filter, power spectrum suggests an uneven packing of grains. For both filters, the total void fraction measured by image analysis was very close to the value determined ‘physically’ knowing the carbon mass, bulk density and filter dimension.

Similar content being viewed by others

References

K. Sutherland, Filters and Filtration Handbook, 5th edn. (Elsevier, Burlington, 2008)

M.B. Hochking, Handbook of Chemical Technology and Pollution Control, 3rd edn. (Elsevier, Amsterdarm, 2005)

L.K. Wang, N.C. Pereira, Y.-T. Hung (eds.), Air Pollution Control Engineering (Humana Press Inc., Totowa, 2004)

R.T. Yang, Gas Separation by Adsorption Processes (Imperial College Press, London, 1997)

W.H.B. Revoir, C.T. Respiratory Protection Handbook (CRC Press LLC, Boca Raton, 1997)

P.A. Schweitzer, Handbook of Separation Techniques for Chemical Engineers (McGraw-Hill Companies, New York, 1999)

A.J. Sederman, M.L. Johns, P. Alexander, L.F. Gladden. Magn Reson Imaging 16, 497 (1998)

M. Suzuki, T. Shinmura, K. Iimura, M. Hirota. Study of Wall Effect on Particle Packing Structure using X-ray Micro Computed Tomography, in Proceedings of 5th World Congress on Industrial Process Tomography, ed. by, Bergen, Norway, 2007, pp. 304

W. Kwapinski, M. Winterberg, E. Tsotsas, D. Mewes, Chem. Eng. Technol. 27, 1179 (2004)

M. Suzuki, T. Shinmura, K. Iimura, M. Hirota, Adv. Powder Technol. 19, 183 (2008)

A. Leonard, H. Wullens, S. Blacher, P. Marchot, D. Toye, M. Crine, P. Lodewyckx, Sep. Pur. Technol. 64, 127 (2008)

P. Lodewyckx, S. Blacher, A. Leonard, Adsorption 12, 19 (2006)

K.A.M. Gasem, J. Robinson, R.L., L.R. Radovic. Sequestering carbon dioxide in Coalbeds, (Oklahoma State University, 2001)

L.A. Feldkamp, L.C. Davis, J.W. Kress, J. Opt. Soc. Am. A. 1, 612 (1984)

P. Soille, Morphological Image Analysis—Principles and Applications (Springer, New York, 1999)

M. Winterberg, E. Tsotsas, AICHE J. 46, 1084 (2000)

B. Eisfeld, K. Schnitzlein, Chem. Eng. Sci. 56, 4321 (2001)

S.M. White, C.L. Tien, Heat Mass Transfer 21, 291 (1987)

D. Vortmeyer, J. Schuster, Chem. Eng. Sci. 38, 1691 (1983)

L.H.S. Roblee, R.M. Baird, J.W. Tierney, AICHE J. 4, 460 (1958)

C.G. du Toit, Nucl. Eng. Design 238, 3073 (2008)

A.L. Negrini, A. Fuelber, J.T. Freire, J.C. Thomeo, Braz. J. Chem. Eng. 16, 421 (1999)

K. Schnitzlein, Chem. Eng. Sci. 56, 579 (2001)

A.J. Sederman, P. Alexander, L.F. Galdden, Powder Technol. 117, 255 (2001)

J. Theuerkauf, P. Witt, D. Schwesig, Powder Technol. 165, 92 (2006)

R.F. Benenati, C.B. Brosilow, AICHE J. 8, 359 (1962)

K.V. Sita Ram Rao. Wall Effects in Packed Beds, vol. PhD Thesis, Indian Institute of Science, (Bangalore, India, 1994)

W. van Antwerpen, C.G. du Toit, P.G. Rousseau, Nucl. Eng. Design 240, 1803 (2010)

A.J. Sederman, M.L. Johns, A.S. Bramley, P. Alexander, L.F. Gladden, Chem. Eng. Sci. 52, 2239 (1997)

D. Toye, P. Marchot, M. Crine, A.M. Pelsser, G. L’Homme, Chem. Eng. Process 37, 511 (1998)

S. Torquato, T.M. Truskett, P.G. Debenedetti, Phys. Rev. Lett. 84, 2064 (2000)

G.D. Scottand, D.M. Kilgour, Brit. J. Appl. Phys. 2, 863 (1969)

Acknowledgments

M.C. Almazan Almazan acknowledges financial support of Ministerio de Educación y Ciencia (MEC) and Fundación Española para la Ciencia y la Tecnología (FCYT) as a postdoctoral contract. The authors also acknowledge the Interuniversity Attraction Pole (IAP-P6/17) for financial support. A. Léonard and N. Job thanks the FRS-FNRS (Fund for Scientific Research) for their Research Associate and Postdoctoral Researcher positions, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Almazán-Almazán, M.C., Léonard, A., Job, N. et al. Three-dimensional void space structure of activated carbon packed beds. J Porous Mater 18, 761–766 (2011). https://doi.org/10.1007/s10934-010-9438-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-010-9438-5