Abstract

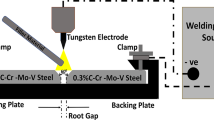

Formation of residual stress as a result of welding process is a familiar fact, but its relation with material composition is unknown. This study aims to investigate the effect of carbon content on welding residual stress in carbon steels. For this purpose, samples of ultra-low carbon interstitial free, low carbon and medium carbon steels are selected. Welding is performed as a beam on plate in spite of a joining process. Weld grooves are prepared at center of the rectangular samples. Automated submerged arc technique is preferred for welding process in order to ensure same welding parameters at each sample. Ultrasonic sound waves are used to determine residual stress. This non-destructive technique provides bulk residual stress which is average of shear and normal stresses through thickness of a material. A new approach is practiced to verify experimentally determined bulk residual stress with finite element simulation results. The model geometry of numerical analysis is divided into equivalent parts and average of shear and normal stresses is calculated. Non-destructive ultrasonic technique seems to be in good agreement with finite element analysis.

Similar content being viewed by others

References

Scott, M., Barnett, D., Ilic, D.: The nondestructive determination of residual stress in extruded billets from acoustoelastic measurements. In: IEEE Symposium on Ultrasonics, pp. 265–268 (1979)

Sanderson, R., Shen, Y.: Measurement of residual stress using laser-generated ultrasound. Int J Press. Vessel. Pip. 87(12), 762–765 (2010)

Doxbeck, M., Hussain, M.A., Frankel, J., Abbate, A.: Use of laser generated creeping longitudinal waves to determine residual stresses. In: IEEE Symposium on Ultrasonics, pp. 725–728 (2000)

Uzun, F., Bilge, A.N.: Immersion ultrasonic technique for investigation of total welding residual stress. Procedia Eng. 10(0), 3098–3103 (2011). doi:10.1016/j.proeng.2011.04.513

Murata, Y., Morinaga, M., Hashizume, R., Takami, K., Azuma, T., Tanaka, Y., Ishiguro, T.: Effect of carbon content on the mechanical properties of 10Cr–5W ferritic steels. Mater. Sci. Eng. A 282(1), 251–261 (2000)

Liu, L., Li, Q., Liu, X., Gao, Y., Ren, X., Liao, B., Yang, Q.: Stress field simulation of carburized specimens with different carbon content during quenching process. Mater. Lett. 61(4), 1251–1255 (2007)

Guo, J., Yang, S., Shang, C., Wang, Y., He, X.: Influence of carbon content and microstructure on corrosion behaviour of low alloy steels in a Cl containing environment. Corros. Sci. 51(2), 242–251 (2009)

Zhang, C., Xia, Z.-X., Yang, Z.-G., Liu, Z.-H.: Influence of prior austenite deformation and non-metallic inclusions on ferrite formation in low-carbon steels. Int. J. Iron Steel Res. 17(6), 36–42 (2010)

Li, Q., Wang, T.-S., Li, H.-B., Gao, Y.-W., Li, N., Jing, T.-F.: Warm deformation behavior of steels containing carbon of 0. 45 % to 1. 26 % with martensite starting structure. Int. J. Iron Steel Res. 17(5), 34–37 (2010)

Zhang, X., Wang, S., Zhang, Y., Esling, C., Zhao, X., Zuo, L.: Carbon-content dependent effect of magnetic field on austenitic decomposition of steels. J. Magn. Magn. Mater. 324(7), 1385–1390 (2012)

Narayan, S., Rajeshkannan, A.: Influence of carbon content on strain hardening behaviour of sintered plain carbon steel preforms. Int. J. Iron Steel Res. 18(9), 33–40 (2011)

Serajzadeh, S., Taheri, A.K.: An investigation into the effect of carbon on the kinetics of dynamic restoration and flow behavior of carbon steels. Mech. Mater. 35(7), 653–660 (2003)

Itabashi, M., Kawata, K.: Carbon content effect on high-strain-rate tensile properties for carbon steels. Int. J. Impact Eng. 24(2), 117–131 (2000)

Guo, J., Shang, C.-J., Yang, S.-W., Wang, Y., Wang, L.-W., He, X.-L.: Effect of carbon content on mechanical properties and weather resistance of high performance bridge steels. Int. J. Iron Steel Res. 16(6), 63–69 (2009)

Committee AIH: ASM Handbook: Heat Treating, vol 4. Asm Intl, Russell Township (1991)

DuPont, J., Marder, A.: Thermal efficiency of arc welding processes. Weld. J. Incl. Weld. Res. Suppl. 74(12), 406s (1995)

Phani, K.K., Phani, D., Sengupta, A.K.: Estimation of elastic properties of nuclear fuel material using longitudinal ultrasonic velocity—a new approach. J. Nucl. Mater. 366(1—-2), 129–136 (2007). doi:10.1016/j.jnucmat.2006.12.045

Thurston, R.: Wave propagation in fluids and normal solids. Phys. Acoust. 1 (Part A), 1–110 (1964)

Lu, J., James, M., Roy, G.: Handbook of measurement of residual stresses. Fairmont Press, Lilburn (1996)

Hughes, D.S., Kelly, J.: Second-order elastic deformation of solids. Phys. Rev. 92(5), 1145 (1953)

Murnaghan, F.D.: Finite Deformation of an Elastic Solid. Dover Publications, New York (1967)

Egle, D., Bray, D.: Measurement of acoustoelastic and third-order elastic constants for rail steel. J. Acoust. Soc. Am. 60(3), 741–744 (1976)

Vangi, D.: Stress evaluation by pulse-echo ultrasonic longitudinal wave. Exp. Mech. 41(3), 277–281 (2001)

Hibbitt, H.D., Marcal, P.V.: A numerical, thermo-mechanical model for the welding and subsequent loading of a fabricated structure. Comput. Struct. 3(5), 1145–1174 (1973)

Andersson, B.: Thermal stresses in a submerged-arc welded joint considering phase transformations. J. Eng. Mater. Tech. 100(4), 356–362 (1978)

Shim, Y., Feng, Z., Lee, S., Kim, D., Jaeger, J., Papritan, J., Tsai, C.: Determination of residual stresses in thick-section weldments. Weld. J. 71(9), 305–312 (1992)

Nickell, R.E., Hibbitt, H.D.: Thermal and mechanical analysis of welded structures. Nucl. Eng. Des. 32(1), 110–120 (1975)

Friedman, E.: Analysis of weld puddle distortion and its effect on penetration. Weld. J. 57(6), 161 (1978)

Mahin, K., MacEwen, S., Winters, W.: Evaluation of residual stress distributions in a traveling GTA weld using finite element and experimental techniques. Model. Control Cast. Weld. Process IV:339–350 (1988)

Friedman, E.: Thermomechanical analysis of the welding process using the finite element method. J. Press. Vessel Technol. 97(3), 206–213 (1975)

Mahin, K., Winters, W., Holden, T., Hosbons, R., MacEwen, S.: Prediction and measurement of residual elastic strain distributions in gas tungsten arc welds. Weld. J. 70(9), 245s–260s (1991)

Bae, K., Na, S., Park, D.: A study of mechanical stress relief (MSR) treatment of residual stresses for one-pass submerged arc welding of V-grooved mild steel plate. Proc. Inst. Mech. Eng. Part B 208(3), 217–227 (1994)

Goldak, J., Chakravarti, A., Bibby, M.: A new finite element model for welding heat sources. MTB 15(2), 299–305 (1984). doi:10.1007/BF02667333

ANSYS Release 13, Finite Element Analysis Software Help Document. ANSYS Inc., Pennsylvania (2010)

Kundu. T., Placko, D.: Advanced Ultrasonic Methods for Material and Structure Inspection. Wiley, New York (2013)

Hsu, N.: Acoustical birefringence and the use of ultrasonic waves for experimental stress analysis. Exp. Mech. 14(5), 169–176 (1974). doi:10.1007/BF02323061

Burrascano, P., Callegari, S., Montisci, A., Ricci, M., Versaci, M.: Ultrasonic Nondestructive Evaluation Systems: Industrial Application Issues. Springer International Publishing, New York (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uzun, F., Bilge, A.N. Ultrasonic Investigation of the Effect of Carbon Content in Carbon Steels on Bulk Residual Stress. J Nondestruct Eval 34, 11 (2015). https://doi.org/10.1007/s10921-015-0284-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-015-0284-x