Abstract

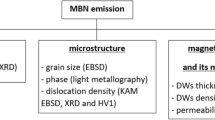

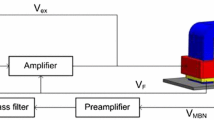

The aim of this study is to monitor nondestructively the degree of spheroidization in steels by Magnetic Barkhausen Noise (MBN) method. Various series of specimens consisting of either lamellar pearlite or partially/completely spheroidized carbides were produced from AISI 1060 steel by appropriate heat treatments. All specimens were characterized by metallographic examinations, hardness and MBN measurements. The results show that MBN signals are very sensitive to the variations in the microstructure caused by the spheroidizing heat treatment. The change of microstructure, from coarse lamellar carbides to uniformly dispersed spherical carbides in ferrite matrix, is reflected as higher Barkhausen activity due to less effective pinning of domain walls.

Similar content being viewed by others

References

Montalenti, G.: Barkhausen noise in ferromagnetic materials. Z. Angew. Phys. 28, 295–300 (1970)

Gaunt, P.: Magnetic coercivity. Can. J. Phys. 65, 1194–1199 (1987)

Williams, H.J., Bozorth, R.M., Shockley, W.: Magnetic domain patterns on single crystals of silicon iron. Phys. Rev. 75, 155–178 (1949)

Yamaura, S., Furuya, Y., Watanebe, T.: The effect of grain boundary microstructure on Barkhausen Noise in ferromagnetic materials. Acta Mater. 49, 3019–3027 (2001)

Blaow, M., Evans, J.T., Shaw, B.A.: Magnetic Barkhausen noise: the influence of microstructure and deformation in bending. Acta Mater. 53, 279–287 (2005)

Saquet, O., Chicois, J., Vincent, A.: Barkhausen noise from plain carbon steels: analysis of the influence of microstructure. Mater. Sci. Eng. A 269, 73–82 (1999)

Moorthy, V., Shaw, B.A., Evans, J.T.: Evaluation of tempering induced changes in the hardness profile of case-carburized EN36 steel using magnetic Barkhausen noise analysis. NDT&E Int. 36, 43–49 (2003)

Moorthy, V., Vaidyanathan, S., Jayakumar, T., Raj, B.: Microstructural characterization of quenched and tempered 0.2% carbon steel using magnetic Barkhausen noise analysis. J. Magn. Magn. Mater. 171, 179–189 (1997)

Davut, K., Gür, C.H.: Monitoring the microstructural changes during tempering of quenched SAE 5140 steel by magnetic Barkhausen noise. J. Nondestruct. Eval. 26, 107–113 (2007)

Koo, K.M., Yau, MY, Ng, D.H.L., Lo, C.C.H.: Characterization of pearlite grains in plain carbon steel by Barkhausen emission. Mater. Sci. Eng. A 351, 310–315 (2003)

Gur, C.H., Ozer, M., Erdogan, M.: Investigation of the variations in microstructure and mechanical properties of dual matrix ductile iron by magnetic Barkhausen noise analysis. Res. ND Eval. 19, 44–60 (2008)

Kaplan, M., Gür, C.H., Erdogan, M.: Characterization of dual-phase steels using magnetic Barkhausen noise technique. J. Nondestruct. Eval. 26, 79–87 (2007)

Kameda, J., Ranjan, R.: Nondestructive evaluation of steels using acoustic and magnetic Barkhausen signals—I. Effect of carbide precipitation and hardness. Acta Metall. 35, 1515–1526 (1987)

Jiles, D.C.: Magnetic properties and microstructure of AISI 1000 series carbon steels. J. Phys. D 21, 1186–1195 (1987)

Lo, C.C.H., Jakubovics, J.P., Scruby, C.B.: Non-destructive evaluation of spheroidized steel using magnetoacoustic and Barkhausen emission. IEEE Trans. Magn. 33, 4035–4037 (1997)

Krauss, G.: Steels: Heat Treatment and Processing Principles. ASM International, Materials Park (1989)

Samules, LE: Optical Microscopy of Carbon Steels. ASM, Ohio (1980)

Atasoy, Ö.E., Özbilen, S.: Pearlite spheroidization. J. Mater. Sci. 24, 281–287 (1989)

Tian, Y.L., Kraft, R.W.: Mechanisms of pearlite spheroidization. Metall. Trans. A 18A, 1403–1414 (1987)

Brooks, C.R.: Microstructural observations of spheroidization from a lamellar structure in iron meteorite. Mater. Charact. 45, 71–80 (2000)

Chattopathyay, S., Sellars, C.M.: Kinetic of pearlite spheroidisation during static annealing and during hot deformation. Acta Metall. 30, 157–170 (1982)

Chattopadhyay, S., Sellars, C.M.: Qualitative measurements of pearlite spheroidization. Metallography 10, 89–105 (1977)

Ranjan, R.: Microstructural Characterization of Ferromagnetic Materials Using Magnetic NDE Techniques. Materials Science and Engineering, p. 115. Iowa State University, Iowa (1987)

Brailsford, F.: Physical Principles of Magnetism. Van Nostrand, New York (1966)

Ryu, K.S., Nahm, S.H., Park, J.S., Yu, K.M., Kim, Y.B., Son, D.: A new non-destructive method for estimating the remanent life of a turbine rotor steel by reversible magnetic permeability. J. Magn. Magn. Mater. 251, 196–201 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Davut, K., Gür, C.H. Monitoring the Microstructural Evolution in Spheroidized Steels by Magnetic Barkhausen Noise Measurements. J Nondestruct Eval 29, 241–247 (2010). https://doi.org/10.1007/s10921-010-0082-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10921-010-0082-4